Table of Contents

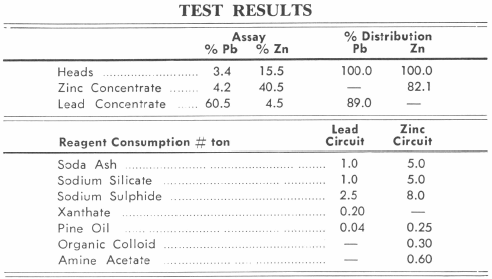

The problem of treating oxidized lead-zinc ores for the production of high-grade lead zinc concentrates is a complex problem due to the nature of the ores and to the soft sliming characteristics of the lead and zinc minerals.

The ore for treatment is a lead-zinc carbonate ore in a mixed siliceous-lime carbonate gangue. The association of the minerals and gangue requires a 65 mesh grind for liberation. The problem is to produce marketable grades of lead and zinc concentrates.

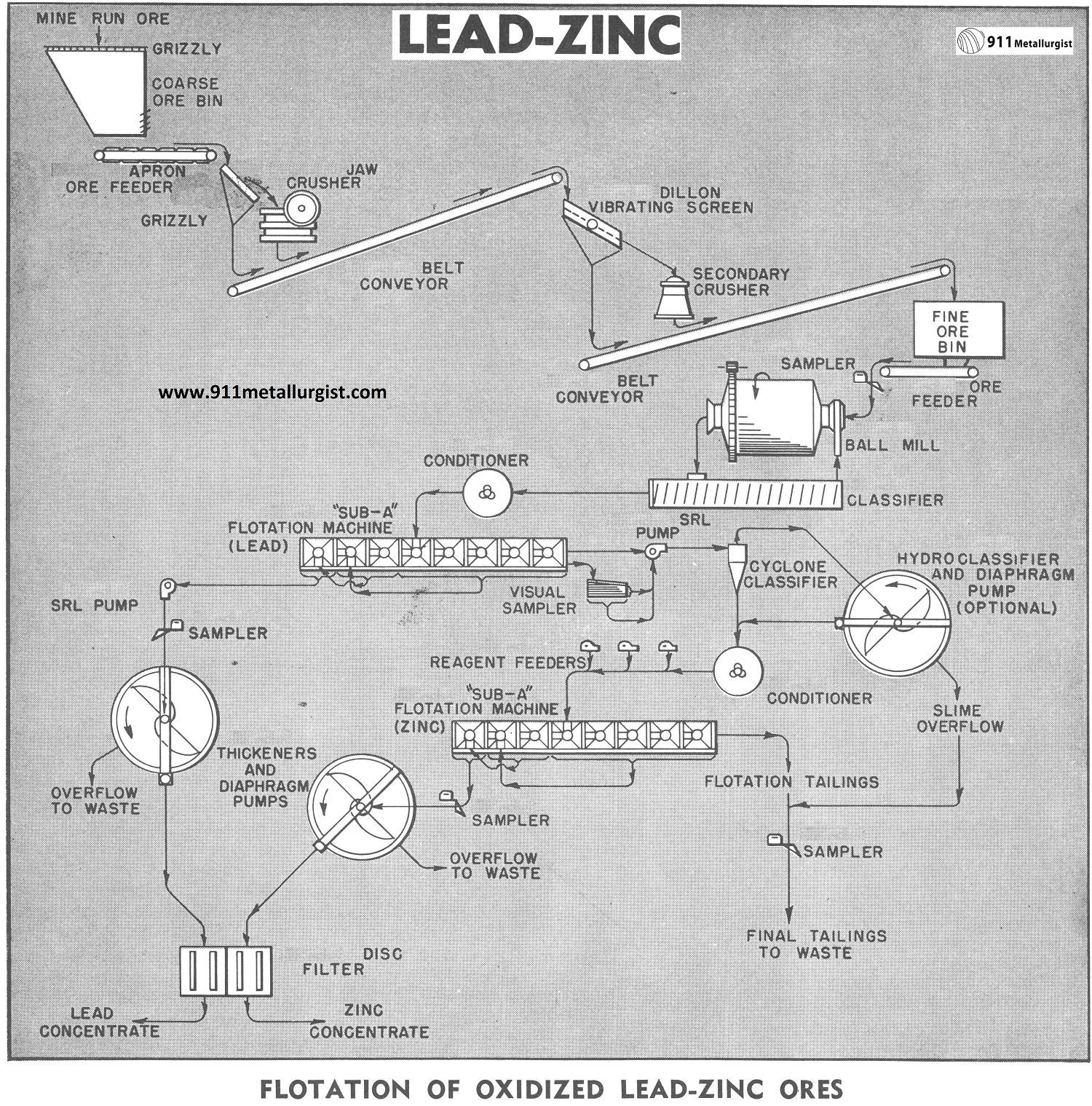

The Flowsheet

This flowsheet was developed from an exhaustive study of the minerals involved. Many theories were explored to answer the objective of producing marketable grades of lead and zinc economically. The simplicity and flexibility of this flowsheet make it particularly desirable in a period of low base metal prices. The use of a sulphidizer to activate the oxidized lead minerals and control and/or removal of reagent consuming slimes is provided ahead of the oxidized zinc flotation section.

Crushing Section

The flowsheet uses a two- stage open circuit crushing section with a capacity of 100-275 tons per 24 hours to reduce the ore to minus ¾ inch for feed to the ball mill. The size of crushing equipment will depend on the size of ore and tonnage of material delivered to the crusher.

GRINDING

The crushed ore minus ¾ inch is fed by means of a belt ore feeder to a Ball Mill which operates in closed circuit with a spiral classifier to produce a minus 65 mesh classifier overflow product.

Conditioning and Flotation

The classifier overflow passes to a Conditioner where sodium sulphide is added to sulphidize the oxidized lead minerals. The sulphidized lead minerals are subjected to flotation using xanthates or mercaptans and pine oil to produce a flotation concentrate which is cleaned two times to produce a high grade marketable lead concentrate.

The flotation tailing from the lead section passes to a wet cyclone to make a primary sand-slime separation. The cyclone overflow passes to a Hydroclassifier which is operated to overflow a turbid overflow which contains the minus 20 micron slimes. This step is often necessary to remove the fine slimes which interfere in the flotation of the oxidized zinc minerals.

The combined underflows from the Hydroclassifier and cyclone represent the feed to the zinc flotation section. The combined products flow to a zinc conditioner where soda ash, sodium silicate and an organic colloid are added to disperse the pulp and complex the slimes which might interfere with flotation. The additional reagents required for the zinc flotation consist of sodium sulphide, primary amines and a frother which are added to the conditioner discharge in the order stated and prior to entering the flotation machines. The rougher zinc concentrate is cleaned two times to produce a high grade zinc concentrate.

The lead and zinc flotation was conducted in “Sub-A” Flotation Machines which provides for the maximum grade of concentrates and the maximum flexibility for the continuous retreatment of the cleaner middlings.

Thickening and Filtering

The final lead and zinc concentrates are pumped by concentrate pumps to Thickeners for dewatering prior filtration. The thickener underflow at approximately 50% solids is pumped to a Disc Filter by means of a Diaphragm pump. The filter cakes pass to concentrate bins for storage.

Sampling

Automatic Samplers are used to sample the feed, concentrate and tailings. A portion of the tailing from the lead flotation section is removed and treated on the Visual Sampler. The flotation results and conditions can be controlled easily by observing the concentrate streak on the table.

ORE TESTING LABORATORY

The Ore Testing Laboratory is available to help you determine the proper flowsheet for your Ore. There is no substitute for experience. Consultation is without obligation. Charges for test work represent out out-of-pocket expenses only and are recommended as a means of eliminating risk in mining investments.

Source: This article is a reproduction of an excerpt of “In the Public Domain” documents held in 911Metallurgy Corp’s private library.