Table of Contents

We investigated a particle agglomeration technique for improving the flow of leaching solution through heaps of clayey or crushed, low-grade gold-silver ores, wastes, and tailings. This technology has been adopted on a broad scale by the precious-metals-processing industry. This report presents information on five commercial operations that have benefited from agglomeration technology and that represent a cross section of current heap leaching practice. The technology is cost effective because of decreased leach times and improved precious metal recoveries.

Exploration identified numerous low-grade precious metal deposits, mine waste materials, and tailings piles throughout the Western United States. The increase in precious metal prices during this period generated interest in processing these low-grade feed materials by low-cost heap leaching technology. Heap leaching with cyanide was applied to many of the materials; however, many conventional operations were unsuccessful because excessive amounts of clay in the feed or fines generated during crushing prevented a uniform flow of cyanide solution through the heaps.

As part of its research program to improve the recovery of gold and silver from low-grade domestic resources, the Bureau of Mines investigated agglomeration pretreatment to overcome the percolation problems associated with heap leaching. Agglomeration of the clays and fines before heap building permitted a uniform and rapid flow of cyanide leaching solution through the heaps. Previous Bureau publications describe bench- and pilot-scale experiments showing the advantages of particle agglomeration as a pretreatment for materials that are difficult to treat by standard heap leaching techniques.

This report shows how the Bureau’s research on agglomeration-heap leaching has been adopted and applied by the precious-metals-processing industry. It describes five commercial operations, ranging in size from 20 to 3,000 tpd and representing a cross section of current heap leaching practice, that have benefited from agglomeration technology. The problems they experienced in trying to apply conventional heap leaching to ores containing clay ranged from complete plugging of the heap, with no solution flow, to slow solution flow, with long leaching times for precious metal recovery. Agglomeration pretreatment effectively resolved the heap permeability problems encountered by these operators.

Agglomeration Concept

Most precious metal ores require crushing to minus 1 in or finer before agglomeration. Crushing to these sizes liberates precious metal values and improves overall recovery. Crushed ores can be agglomerated by mixing 5 to 10 lb portland cement per ton of dry feed, wetting with 8 to 16 pct moisture as either water or strong cyanide solution, mechanically tumbling the wetted mixture, and curing the agglomerated feed for a minimum of 8 hr before heap leaching. The quantity of cement added during agglomeration usually provides the protective alkalinity required for cyanide leaching. After agglomeration and heap building, leaching is conducted with conventional heap leaching techniques.

During agglomeration, the clay and fine particles contained in the ore adhere to the coarser particles and create a coating of fines around the coarse particles. The agglomerates produced are of sufficient green strength after curing to withstand wetting with minimal degradation. Agglomeration overcomes the major problems associated with particle segregation during heap building, fines migration, and solution channeling during leaching by producing a porous, permeable feed.

A permeable feed material stacked in a heap permits the uniform flow of leaching solution and contact of the cyanide leaching solution with the exposed precious metal particles and decreases the leaching time required to obtain targeted precious metal recovery.

Why is Agglomeration Needed

The main reason for agglomerating heap leachable ores is to prevent percolation problems in a heap. This is considerably different than the reasons for pelletizing iron ore where the purpose is to bond very finely ground material into coarser, strong particles that can withstand the rigors of transportation and the loading forces in a blast furnace. Most percolation problems in heaps are caused by the segregation of coarse and fine particles during heap construction. This segregation creates localized areas with significantly lower permeability because fines plug the channels between coarse particles. As a consequence, the leach solutions follow the path of least resistance, percolating downward through the coarse ore-areas and bypassing or barely wetting areas that contain large amounts of fines. Lower extraction, longer leach time, and higher reagent consumption are the results.

Permeability problems are compounded in heap leaching because of the vertical migration of fine particles after the heap has been built. These fines eventually accumulate in pockets or layers and impede uniform solution flow. The fines move because they are not attached to a coarser particle or because of the sluicing action of leach solution flowing over the surface of particles at a rate that breaks the bond between fine and coarse particles. Some fines are also created by the decomposition of ores after being wetted. The movement of fines within the heap causes channeling of solution flow which, as previously stated, causes decreased metal recovery, slower recovery rate, increased leach time, and increased reagent consumption.

Percolation problems are minimized if the fines can be attached to the coarser particles so they are uniformly distributed and rendered immobile within the heap. Comparative tests of nonagglomerated and agglomerated gold and silver ores (Heinen, 1979) showed that percolation rates through agglomerated material usually are improved by a factor of 10 to 100 times. This reduces leach time for economic recovery to less than one-third of that for nonagglomerated material, and total recovery may be increased. Cyanide consumption is also reduced in most cases because of the shortened leach time.

Overall, agglomeration allows the application of low cost heap leaching technology to gold and silver ores and tailings which may not be economically processed by conventional methods, according to Phariss (1982).

Commercial Agglomeration Heap Leaching Operations

Gold Heap Leaching 20 TPD

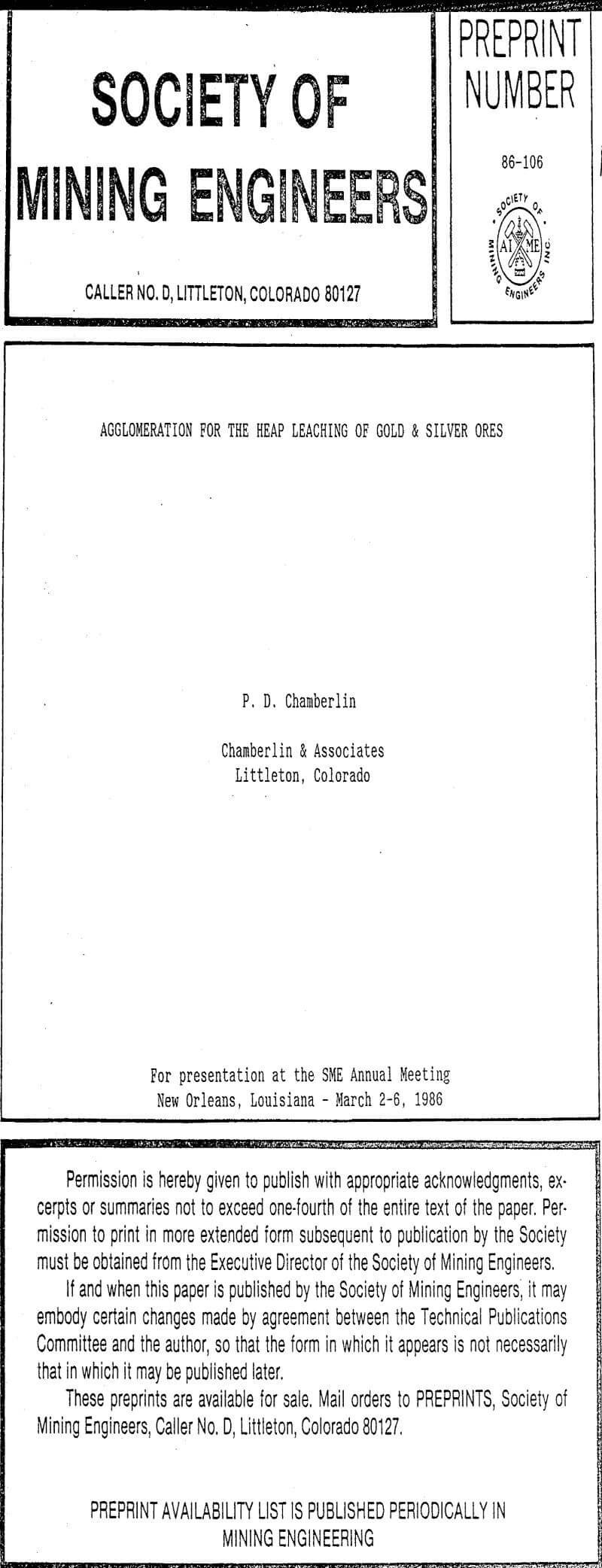

A small Arizona operation (fig. 1) processing 20 tpd of gold ore changed to agglomeration technology after conventional heap leaching was unsuccessful because of inadequate leaching solution percolation.

The oxidized disseminated deposit contains an average 0.2 tr oz of gold per ton. The host rock is porous and the gold particles are exposed. The ore is mined from an open pit, transported to the crushing plant by a front-end loader, crushed to a nominal 3/8-in feed size, and conveyed to a drum agglomerator.

The drum agglomerator is 3 ft in diameter and 7 ft in length. A static scraper, located lengthwise in the top portion of the drum, prevents excessive buildup of clayey material. A spray bar adjacent to the scraper emits a spray that covers a 5-ft length of the drum. The drum slopes 5° from feed to discharge end and rotates at 17 rpm. Feed retention time is 20 sec. The drum can agglomerate 10 tph of dry feed.

The minus 3/8-in feed material is mixed with 10 lb portland cement (type II) per ton of dry feed before discharge from the feed conveyor, and the mixture is blended in the first foot of the drum. The ore- binder mixture is wetted by the spray bar with a solution containing 2 lb NaCN per ton. Total moisture required for agglomeration is 10 pct. On discharge from the drum, the agglomerated ore is conveyed to an impervious leaching pad and stacked into a 7-ft-high heap that contains 100 tons. The agglomerated ore is cured in the heap for 48 hr before leaching.

The heap is leached in 5 days by spraying solution containing 1 lb NaCN per ton over the heap at a rate of 0.033 gpm/ft². The cement added during agglomeration is sufficient for protective alkalinity. The dissolved gold is recovered from the pregnant solution by passing the solution upward through four 14-in by 5-ft carbon columns at a rate of 20 gpm/ft². The barren solution is recycled to the heap.

The loaded carbon is stripped with an alkaline-alcohol solution. The precious metal values are electrowon from solution on steel wool cathodes in a cylindrical electrowinning cell. The gold-laden cathodes are treated with nitric acid to dissolve excess iron, and the resultant sludge is fire refined to produce a dore bullion.

Gold recoveries obtained by agglomeration and heap leaching average 90 pct. Agglomeration pretreatment improved heap permeability, percolation rate, gold recovery, and decreased the leaching period required to obtain the targeted recovery.

Gold Vat Leaching 1500 TPD

In this operation; the agglomerated feed is leached in large vats rather than in heaps. The operation is located in the Colorado Rocky Mountains southwest of Denver at an elevation of 10,000 ft.

The gold ore occurs in an oxidized disseminated deposit and averages 0.06 tr oz of gold per ton with trace amounts of silver. The host rock is porous and the gold is liberated by crushing. The ore is mined from an open pit and is friable. Seventy-five percent of the deposit can be mined with dozers and front-end loaders. The remaining 25 pct must be drilled and blasted. The operation mines and processes 1,500 tons of ore per day. All the material mined is ore; there is no waste rock.

The mined ore is transported by front-end loader to the in-pit crushing plant where it is crushed to a ½-in size by two-stage crushing. The minus ½-in feed is conveyed uphill one-fourth mile to the processing plant. The ore transport conveyor system is cheaper to operate than truck transport, which keeps the mining costs extremely low.

The transport conveyor discharges the crushed ore onto a surge pile outside the agglomeration-vat leaching building. The enclosed building permits year-round operation. From the surge pile the ore is fed to an 8-½- by 32-ft rotating drum (fig. 2). The drum slopes 8°, with the feed end elevated, and rotates at 10 rpm. The walls of the drum are not scraped because the agglomerated feed does not build up excessively.

The ore is mixed with 10 lb of binder (3 lb portland cement (type II), 7 lb fly ash) per ton of feed in the first few feet of the drum. The material is sprayed with a pH 12 solution containing 10 lb NaCN per ton. A 20-ft spray bar inside the drum is used to increase the moisture content of the feed to 13 pct. Mechanical tumbling occurs along the length of the drum. The agglomerated feed is conveyed to a stockpile from which the leaching vats are loaded by a front-end loader. Curing occurs while the vats are being loaded.

The feed is placed into one of four inclined vats measuring 80 by 50 ft. The deepest portion of the vat is 9 ft. Each vat contains 1,000 tons of agglomerated feed and requires 4 hr to load.

The ore is leached by spraying solution at the rate of 0.05 gpm/ft² until the vat is full. The solution in the vat is circulated and sprayed by pumps throughout the leaching cycle to insure an adequate dissolved oxygen content (fig. 3).

Gold recovery is 90 pct in a 3-day leaching and washing cycle. The vats drain in approximately 8 hr. The moisture retained by the leached residue is 13 pct, the same amount of moisture required for agglomeration, so there is no entrained gold-bearing solution in the residue. The plant capacity was designed for 1,000 tpd, but changing the leaching- washing cycle from 4 to 3 days allows 1,500 tons of agglomerated ore a day to be processed.

The pregnant solution from the vats is pumped to a carbon adsorption system for gold recovery. The carbon system consists of four adsorption tanks, each containing 1.5 tons of 6- by 12-mesh coconut shell activated carbon. When the lead carbon is loaded to 200 tr oz of gold per ton, it is educted to the desorption circuit. Fresh carbon is kept in the last tank in the solution flow sequence to insure a good barren solution. The barren solution is pumped to a holding tank for recycle to the leaching vats. All reagent makeup is done during agglomeration.

The loaded carbon is desorbed in 8 hr by caustic cyanide solution at 116° C and 25 psig pressure. The pregnant solution from desorption is passed through one of four cylindrical electrowinning cells where the gold is deposited on steel wool cathodes. The cathodes are directly fire refined to produce dore bullion containing 80 pct gold and 17 pct silver.

Preliminary metallurgical testing had shown conventional heap leaching to be unsatisfactory. Agglomeration increased permeability, percolation rate, and gold recovery. Agglomeration permits a very short leaching cycle, which allows for increased gold production.

Silver Heap Leaching 2000 TPD

A silver agglomeration-heap leaching operation is located near Tombstone, Ariz. Two types of materials are mined: old waste material that was used for mine backfill and virgin ore adjacent to the waste material. The waste material is mined with front-end loaders to expose the virgin ore. The virgin ore is drilled and blasted and moved by front-end loader. The silver content of the two feed materials varies. The cutoff grade of feed to the heaps is 1.0 tr oz of silver per ton. Approximately 2,000 tpd of ore is mined and agglomerated.

The mined ore and waste are moved from a stockpile to the crushing plant where they are crushed to a nominal ½ in. Lime (7 lb/ton of ore) is used as the binder for agglomeration and is mixed with the ore during secondary crushing. The crushed ore-lime mixture is conveyed to an underground ore stockpile. Some moisture is sprayed onto the ore on the crusher discharge conveyor to decrease dusting.

The ore from the underground stockpile is agglomerated on a reverse belt conveyor designed by the operators (fig. 4). The 4- by 25-ft belt agglomerates ore at a rate of 200 tph. The agglomerating conveyor can be set at an angle between 35° and 45°, and the belt travels upward while the ore moves down the belt. The angle and speed of the belt can be varied to provide the desired retention time of ore on the belt. Water is sprayed at several locations along the length of the belt and gives the agglomerated feed a moisture content of between 10 and 12 pct. A small amount of moistened fines adheres to the belt and rides up the conveyor. A scraper was placed on the bottom side of the drive roller to eliminate excessive fines buildup on the belt.

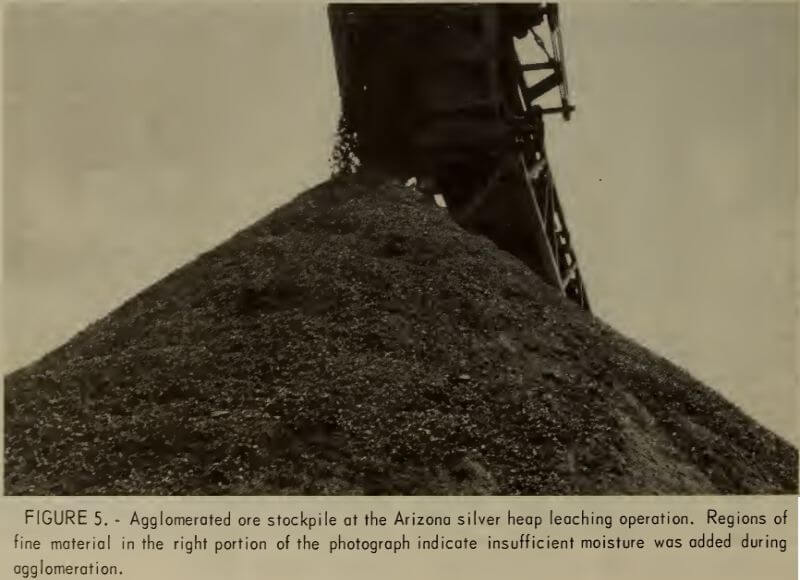

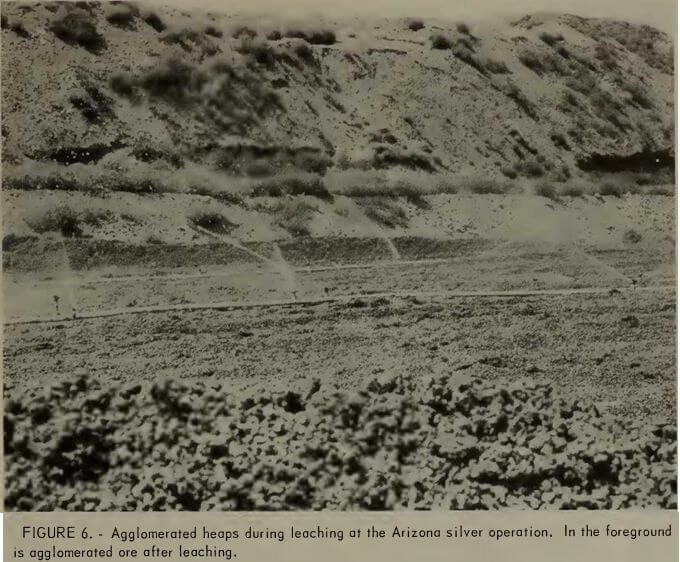

The agglomerated ore is transported to a stockpile by a radial arm stacker (fig. 5). The material from the stockpile is trucked 500 ft to a ¾-acre impervious leaching pad and is allowed to cure during heap building. Five heaps, each containing 6,000 tons of agglomerated ore stacked 10 to 11 ft high, are leached on the pad (fig. 6). Three heaps are at different stages of leaching, while the other two are either being prepared for leaching or being removed from the pad.

The heaps are sprayed with pH 10.5 solution containing 2 lb NaCN per ton at a rate of 0.0075 gpm/ft². The leaching solution percolates through the heap, is collected on the impervious leaching pad, and drains into plastic-lined solution trenches. The leaching and washing cycle is 7 days. The leached residue is transferred to an auxiliary leaching pad and sprayed with cyanide solution 1 day per month for additional precious metal extraction.

Precious metal values in the pregnant solution are recovered by Merrill-Crowe zinc precipitation technology. The precious-metal-bearing zinc precipitates are refined on site and yield dore bullion. The dore is shipped to another facility for refining. The barren solutions are recycled to the heaps.

Heap leaching was unsuccessful before agglomeration pretreatment was applied to the ore. Conventional heap leaching recovered only 37 pct of the leachable silver from 3-in feed material treated in 90-day leaching cycles. Severe percolation problems were encountered. Agglomeration permitted finer crushing, which liberated additional silver values for dissolution by cyanide. Agglomeration heap leaching increased silver recovery to 90 pct of the leachable silver and decreased the leaching time to 7 days.

Gold Heap Leaching 2500 TPD

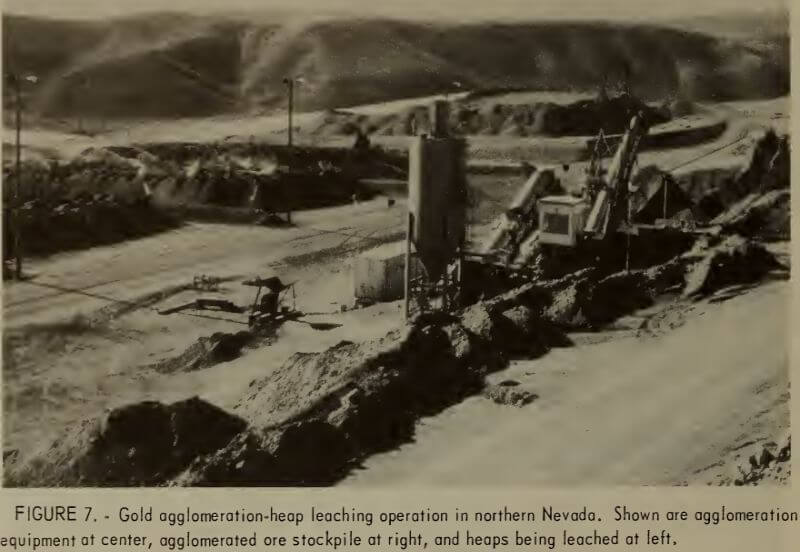

An operation in northern Nevada (fig. 7), which has produced gold by agitation cyanidation and countercurrent decantation for several years, discovered a new ore deposit several miles from the working mine. Higher grade ore from the new deposit is transported to the original mill for gold recovery. Ore containing less than 0.07 tr oz gold per ton is heap leached at the site. Average ore grade for the heap material is 0.034 tr oz gold per ton. The ore is mined by open pit methods and is trucked to the heap leaching site approximately one-half mile from the new pit. About 2,500 tpd of ore is mined and heap leached.

The ore is crushed to minus 5/8 in by a primary jaw crusher and a secondary cone crusher. Portland cement (type II), at the rate of 7 to 10 lb/ton of ore, is added to the ore at the jaw crusher discharge conveyor and is mixed with the ore during secondary crushing. The ore-binder mixture from secondary crushing is conveyed to a radial arm stacker. Water is sprayed onto the mixture at the discharge end of the stacker and gives a final moisture content of 9 to 13 pct. The ore is agglomerated by cascading down the sides of the conical-shaped agglomerated ore stockpile. Additional tumbling, sufficient to effect agglomeration, occurs when the front-end loader loads the rear dump truck with agglomerates from the stockpile and when the truck dumps the agglomerated feed onto the impervious asphalt leaching pad. The agglomerated ore is cured for 2 to 3 days while the heap is being built.

Five 17,000-ton heaps, approximately 12 ft high, are built on the leaching pad. Three heaps are in different stages of the leaching cycle while the remaining two are either being prepared for leaching or being removed from the pad.

The agglomerated heaps are leached by spraying 0.004 to 0.005 gpm/ft² of pH 10-11 solution containing 1.0 lb NaCN per ton of solution. The portland cement added during agglomeration provides most of the alkalinity during leaching, but small quantities of NaOH are added to the

barren solution to maintain the desired value. The leaching and washing cycle is 20 days. Leached residues are transported to a tailings disposal area.

The pregnant solution draining from the leaching pad flows by gravity to a reservoir and is pumped through a series of five carbon adsorption tanks for recovery of dissolved gold values. The gold- loaded, 12- by 30-mesh, coconut shell activated carbon is transported to the millsite for desorption by an alkaline alcohol solution. The values desorbed from the carbon are electrowon on steel wool cathodes, which are refined on site to produce dore bullion.

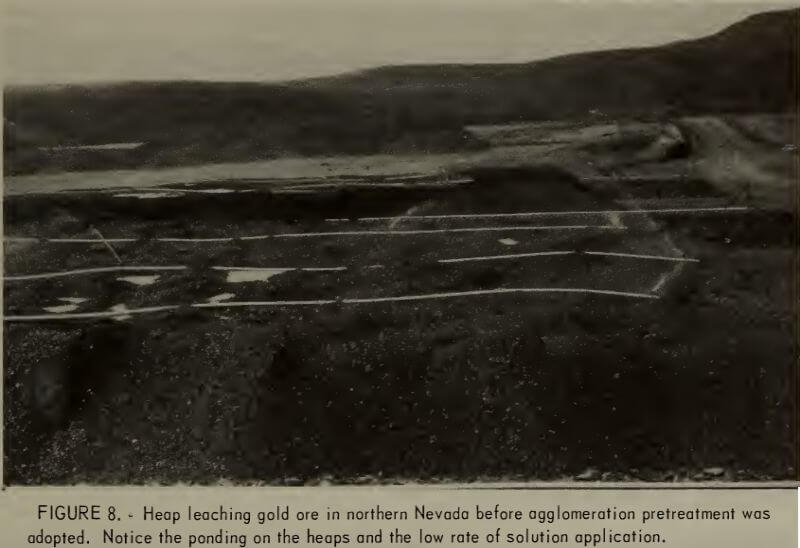

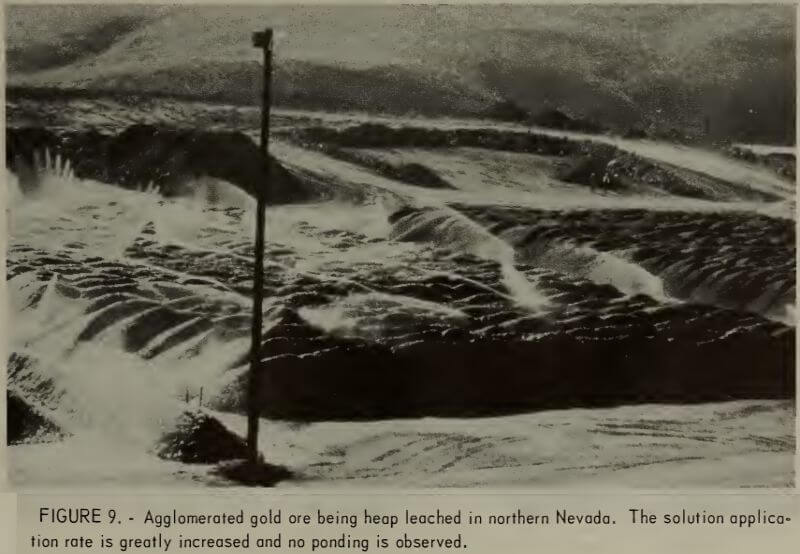

This operation initially tried conventional heap leaching to process the low-grade ore. Conventional heap leaching was unsuccessful because of the high clay content of the ore, particle segregation, and fines migration, which resulted in leaching solution channeling (fig. 8). Agglomeration pretreatment increased gold recovery by 60 pct while decreasing the leaching cycle from 50 days to 20 days (fig. 9). Even with agglomeration, some ore retains approximately 30 pct moisture, and long washing periods are required to recover the dissolved values from the agglomerates. The longer washing cycle extends the total leaching cycle to 30 days for some heaps.

Gold Heap Leaching 3000 TPD

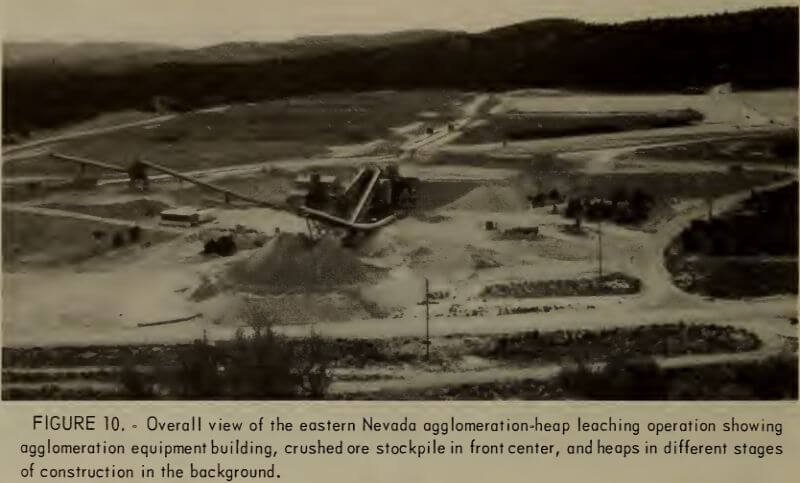

The largest of the operations surveyed is located in eastern Nevada and processes approximately 3,000 tpd of ore (fig. 10). The ore is a silicified siltstone containing finely disseminated

free gold. Gold-bearing carbonaceous ore occurs at depth in the deposit. The average grade of the deposit is 0.10 tr oz gold per ton. The ore is mined by open pit methods and is trucked a short distance to the crushing circuit.

The run-of-mine ore is crushed to a nominal ¾ in by a primary jaw crusher, a standard cone crusher, and a short-head cone crusher. The crushed ore is conveyed into a building where it is agglomerated.

Two types of ore are processed. Some of the oxidized ore contains no clayey material, and crushing it generates very few fines. Only 6 pct of the material is minus 200 mesh. Consequently, it does not require a cement binder for agglomeration. This portion of the ore is agglomerated with cyanide solution to start the leaching process during heap building.

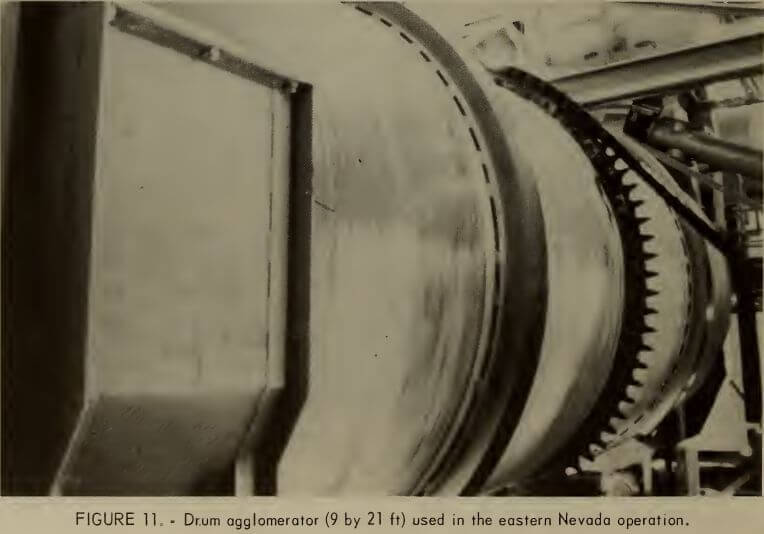

The second type of crushed ore is mixed with 4 to 10 lb of portland cement (type II) per ton of feed in the first portion of a 9- by 21-ft rotating drum agglomerator (fig. 11). Cyanide solution is sprayed onto the mixture in the middle portion of the drum and gives a final moisture content of approximately 8 pct. The mixture agglomerates in the last portion of the drum. The design capacity of the drum agglomerator is 215 tons of dry ore per hour, but it has been operated at 450 tph.

The agglomerated ore is conveyed to a stockpile where it is loaded by front-end loader into trucks for haulage to the impervious leaching pad. The agglomerates cure during the heap building process.

The permanent heaps are built by driving the truck onto the heap and dumping the feed over the edge. A tracked dozer levels the heap, and the surface is ripped before leaching. This heap building procedure is not recommended for agglomeration-heap leaching of ores that are susceptible to compaction. Each heap contains approximately 120,000 tons of agglomerated ore stacked 15 ft high (fig. 12).

The heaps are leached by sprinkling a pH 11.5 solution containing 0.5 lb NaCN per ton of solution at a rate of 0.003 to

0. 005 gpm/ft². The total leaching and washing cycle is from 20 to 80 days and depends on the ore being processed. The pregnant solution collects on the impervious pads and drains to plastic-lined ditches. The solution flows by gravity to a 7-million-gal pregnant solution pond.

Pregnant solution from the pond is pumped through a series of five activated carbon tanks at a rate of 1,000 gpm. The barren solution exiting the fifth carbon tank is pumped to the barren solution pond for reagent makeup and recycle to the heap. The loaded carbon from the lead tank is stripped with a caustic cyanide solution at 120° C and 35 psig pressure. The gold-bearing solution is cooled to 85° C before electrowinning. The solution is pumped through two rectangular electrowinning cells where the gold is deposited on steel wool cathodes. The cathodes are refined on-site to produce dore bullion containing 92 pct gold and 6 pct silver. The dore bars are shipped to a custom refinery for processing.

Recoveries by agglomeration-heap leaching range from 70 to 90 pct, and depend on the ore being processed. Conventional heap leaching was used before the agglomerating equipment was on-line. Gold recoveries were less than 50 pct because of fines migration and the high clay content, which caused blinding and channeling of leaching solution. Agglomeration technology has helped maintain targeted recoveries in shorter leaching periods for heaps with high clay content.

Summary and Conclusions

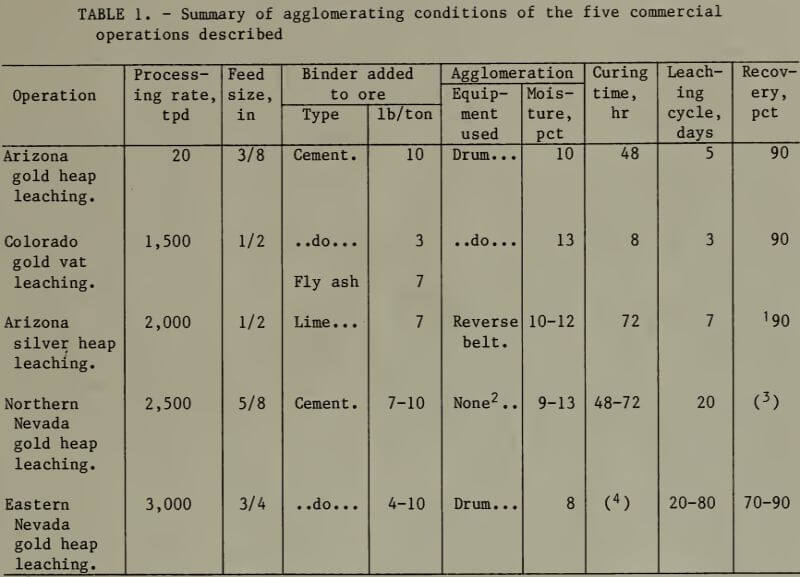

The precious metals industry has rapidly adopted agglomeration-heap leaching technology. The five operations described in this report demonstrate the versatility and applicability of the technology to heap leachable ore types for different size operations. A summary of agglomerating conditions for the operations is shown in table 1. In the Western United States, there are 36 commercial operations using agglomeration-heap leaching technology.

For the operations described, agglomeration pretreatment technology effectively improved heap permeability and permitted better contact of the cyanide leaching solution with the precious metal. As a result, percolation rates increased, leaching periods decreased, and precious metal recoveries were improved over those of conventional heap leaching technology. Agglomeration pretreatment provides certain other advantages. Since the heaps are more permeable and drain rapidly, soluble losses are minimized and intermittent sprinkling is permitted. This is important in arid climates because solution loss by evaporation is minimized by spraying the heaps during night hours when winds and ambient temperature are low. During the period that the heap is not being sprayed, the residual cyanide in the heap continues to dissolve precious metal and enriches the pregnant solution when spraying is resumed. The greater permeability of the heaps permits better washing of dissolved values from the heap and decreases the residual cyanide content of the washed, spent heap.

Even though more reagents and equipment are required for agglomeration-heap leaching than for conventional heap leaching, it is cost effective because of the decrease in leaching time and improved precious metal recoveries.