From time immemorial the methods of assaying any materials for silver and gold were in reality nothing but laboratory smelting methods. The writer arrived in Butte, Mont., he found that these metals, contained in copper bullion, were still determined by the all-fire assay, both in the same charge. There seems to be no record as to when and where the so-called combination method (dissolving the copper in nitric acid and precipitating the silver as chloride, etc.) was first introduced; but in the early nineties of the past century it became evident that for the sake of accuracy of the gold assay this metal must be determined by the all-fire method which, on the other hand, was quite unsatisfactory for silver. The combination method became the standard method for silver and the all-fire the standard for gold. From that time on probably most assayers were longing for a reliable single method for both metals, since the simplicity of the combination method, with its accurate results for silver, contrasted strongly with the unchemical, tedious and expensive all-fire method for gold.

To many, the comparative cost of the all-fire and sulphuric-acid assay-methods may be of interest. For the Anaconda laboratory, of Perth Amboy, it has been calculated with accuracy, that the materials per assay, exclusive of those used in the parting for gold and for the correction-assay (these being approximately the same for both methods), amount to 8.5 cents for the sulphuric-acid method and 75.5 cents for the all-fire method; a saving of 67 cents per assay. The saving in labor, too, is considerable, although its value in our case has hot been established.

The first recorded attempt to modify the combination method in a way to obtain accurate gold results was made by L. D. Godshall, who suggested to reprecipitate any gold that might have gone into solution with the copper by conducting hydrogen-sulphide gas into the solution in sufficient quantity to precipitate all the silver with no copper, or only a minimum quantity thereof. A. R. Ledoux and Cabell Whitehead pointed out the defects of such a method. About the same time W. R. Van Liew showed that accurate gold results could be obtained by modifying the combination method in the way that dilute nitric acid was added in several portions to the metallic copper and the reaction conducted under ice-cooling. The time required for this method was a factor very much against its becoming popular. A new idea was introduced by Thomas B. Swift, who first amalgamated the surface of the copper by means of mercuric nitrate before dissolving the metal with nitric acid. In this method, the surface of each copper particle would remain coated with mercury during the whole process of solution and the mercury would absorb the gold and protect it from any solvent action. The author gave no data regarding silver.

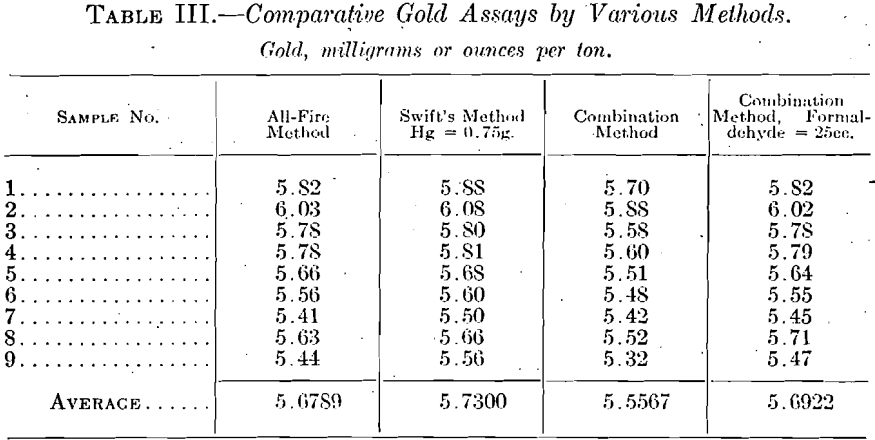

During the period in which the afore-described efforts for a simplified gold assay were made, attempts along the same line were also carried on in the Anaconda laboratory. The idea was to find a reducing medium which would quickly precipitate the gold from the nitric acid solution without precipitating copper in any form. Good results were obtained by boiling the copper nitrate solution (one assay ton of copper), which contained little nitric acid in excess and no nitrous products, with 25 cc. of formaldehyde, strength about 37 per cent. A few comparative results by methods of that time are given in Table III.

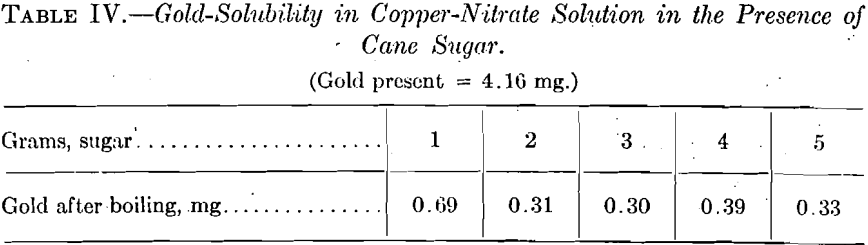

A peculiar phenomenon was observed in trying cane sugar for the same purpose; instead of reducing and precipitating the gold which had been dissolved by the nitric acid, the greater portion of the total gold would be dissolved when the solution was boiled; Table IV gives the data.

It was at first thought that chlorine was present in the sugar and that it was responsible for the solution of the gold, but a test of the sugar solution as well as of the burnt residue revealed but an indistinct trace of that element, so that the following facts may satisfactorily explain the phenomenon. When the copper nitrate solution is boiled with the addition of sugar the latter is quantitatively converted into oxalic acid and this forms, with the copper, an insoluble oxalate. The nitric acid is reduced to free nitrous acid and this will, the oxalic acid being inert, dissolve the gold.

Experiments on these lines were discontinued when, early in 1908, it was learned that Frederic F. Hunt, of New York, had devised a new combination method which yielded good results for silver and for gold. This method consisted in adding to 1 assay ton of copper 10 cc. of.water and 100 cc. of sulphuric acid of 1.84 specific gravity; first heating on a hot-plate and finally on an open flame until complete sulphatizing of the copper was accomplished. There was no solution of the gold and when the silver, or a part of it, was dissolved it was precipitated as chloride and the remaining procedure was the same as that well known in the old combination method. Some difficulty was experienced in sulphatizing the copper to completeness when the sample was too coarse and when

the copper contained appreciable amounts of sulphur. A little later in the same year Albert M. Smoot, of Ledoux & Co., New York, informed the writer that copper first amalgamated superficially and heated with 80 cc. of sulphuric acid (sp. gr. 1.84) per assay ton of copper was an improvement over Hunt’s method. Difficulties in the complete sulphatizing of the copper in certain bullions continued and led to numerous tests in the Anaconda laboratory which resulted in the final adoption of the following routine, by which even coarse drillings and copper shot may be completely sulphatized and of which the resulting gold and silver chloride may be scorified with a total of 20 g. of lead in 2-in. scorifiers and cupelled in 1-in. cupels; the lead buttons weighing 5 g.

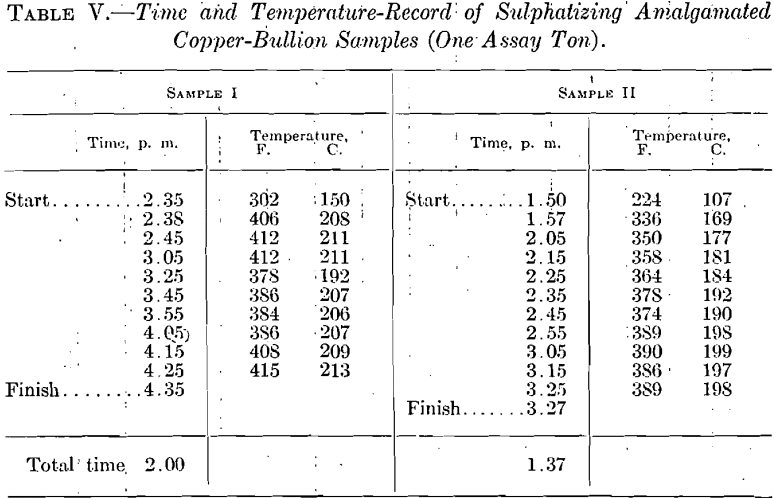

Stock Solutions

Mercuric nitrate, 25 g. of mercury per liter; sulphuric acid, sp. gr. 1.84; sodium chloride, 19 g. per liter (10 cc. will precipitate 350 mg. of silver). The copper bullion drilling sample has been ground to pass a 16-mesh screen and if by test it has been found that the coarse and fine parts, separated by a 40-mesh screen, differ appreciably in precious-metal content the parts are weighed separately in their proper ratio. The fine, 29.166/C/F + 1 grams (C = weight of coarse; F = weight of fine portion of sample), is weighed first and the remainder of the assay ton made up with the coarse. This is now placed in an 800-cc. Jena beaker, Griffin shape, 30 cc. of water and then 10 cc- of the mercuric-nitrate solution added (Hg = 0.25 g.). The beaker is shaken until all the copper appears amalgamated over its surface, then 100 cc. of sulphuric acid is added; the beaker is covered with a 5-in. watch glass and placed on an electric hot-plate. The time necessary to complete the reaction depends on the state of division of the sample; as also on the temperature of the plate. Table V. gives the time and temperature record of two samples.

For about one hour the liquid appears to boil, which, however, is only a bubbling, due to the evolution of sulphur-dioxide gas, from the reduction of the sulphuric acid and the oxidation of the copper. This completed, the supernatant liquid assumes a very dark green color, finally changing to a light grayish blue which, as experience has taught, is the indication of the finishing point. Boiling over an open flame has been abandoned, the excessive heat having been found unnecessary and the act of boiling being bound to entail some loss. The beaker is next removed from the plate and placed to cool on an asbestos sheet. Complete cooling is unnecessary as there is very little free sulphuric acid present. Four hundred and fifty cubic centimeters of water with the necessary amount of sodium chloride solution, the latter, depending on both the amount of the silver and the amount of mercury present, are used. With 80 to 100 mg. of silver and 0.25 g. of mercury for Anaconda material 30 cc. of the stock solution or 0.57 g. of sodium chloride is always a safe quantity. The beaker is again placed on the hot-plate and the solution brought to a

boil, which dissolves the copper sulphate and coagulates the silver chloride. On removal of the beaker 150 cc. more water is added, the total amount now being 600 cc., which is capable of keeping in solution all copper sulphate after, cooling. It is then a matter of expediency to filter immediately or the day after.

Details as to the furnace operations of this method are not deemed to be within the scope of this paper; they are much a matter of individual taste. For the description of mechanical and labor-saving devices the reader is referred elsewhere.

It should be noted that with comparatively pure copper the amount of mercuric nitrate may be reduced, while with copper high in sulphur content an increase in the amount of the mercuric nitrate will be required.

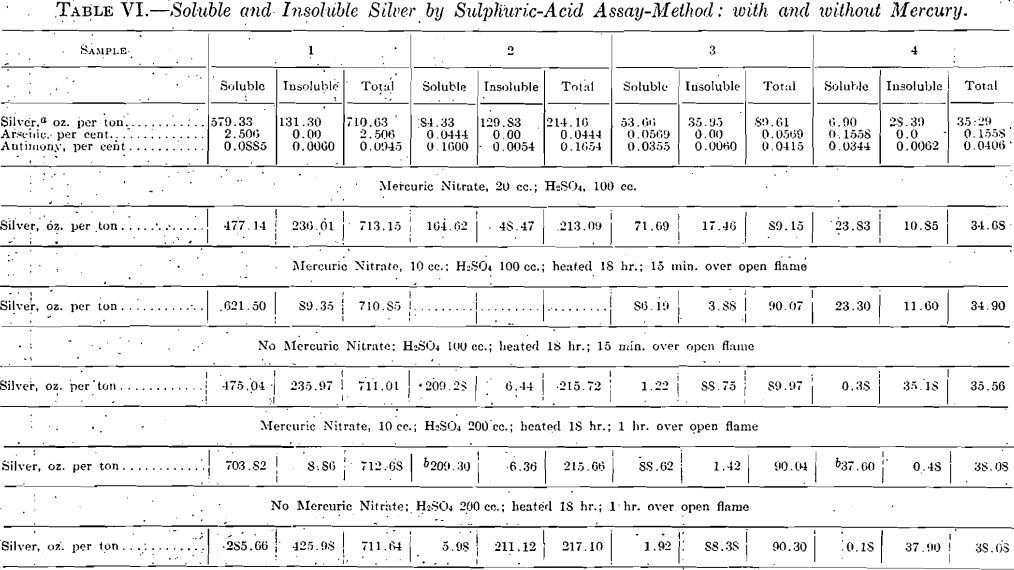

It has been noted as a peculiarity of this method that with certain low-grade bullions none of the silver is rendered soluble and that upon addition of sodium chloride solution no silver chloride is formed. Table VI. gives a variety of data on this subject. It is shown that all of the arsenic and, nearly all of the antimony is dissolved. It was also qualitatively proven that no selenium or tellurium remains in the residue. The insoluble silver, therefore, is not combined with any of these elements.

It was found that with all of the insoluble silver residues: there remained some mercury and with sample No. 4 always a little copper; the latter probably being in the form of sulphide, as this sample contained

by far the most of that element. We may conclude that, although the presence of mercury facilitates the solution of the silver as it does that of the copper, all copper and all mercury must be dissolved before all silver can go into solution. In the ordinary process of the assay, there is not enough sulphuric acid present and the heating is not continued sufficiently long to meet these conditions; therefore, with little silver present none is dissolved, and with much silver present only a portion is rendered soluble.

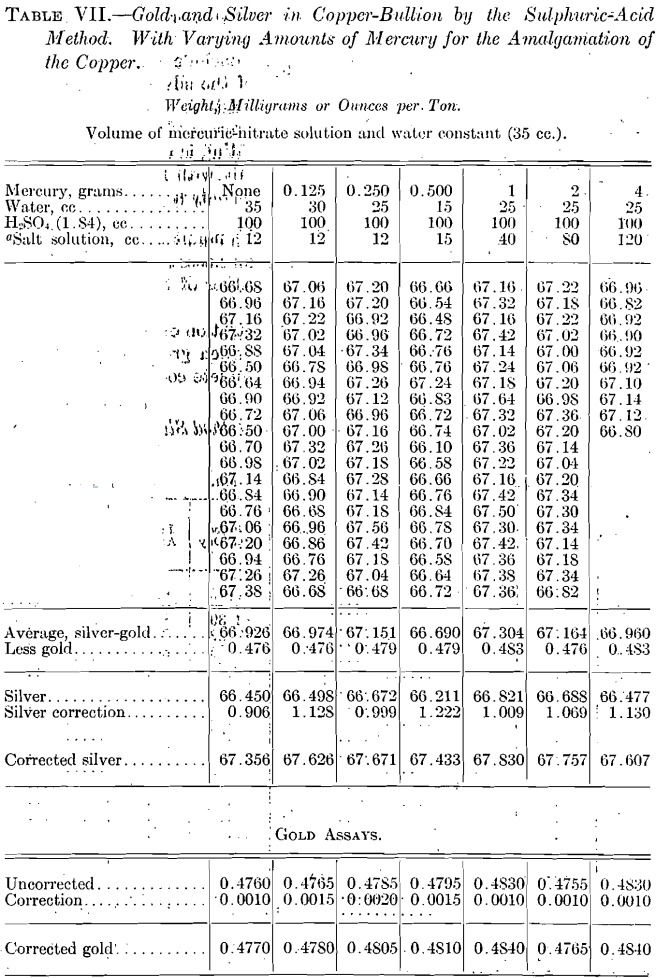

Table VII. demonstrates that, an increased amount of mercury has no marked effect on the silver results if only the necessary increase in the amount of sodium chloride be provided. Neither of the two substances can influence the gold results.

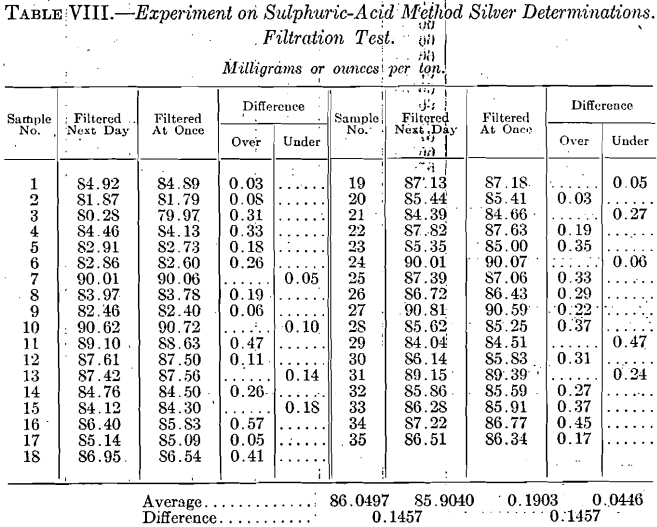

Table VIII. demonstrates that immediate filtration of the silver chloride may be chosen for ordinary purposes, while when great accuracy is desired it is safer to leave it for settling and complete cooling over night.

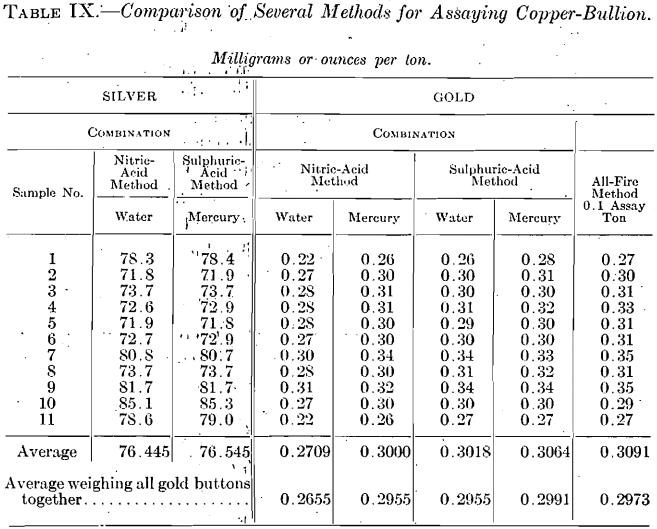

Table IX. gives comparative results for silver and gold; the former by two and the latter by four methods.

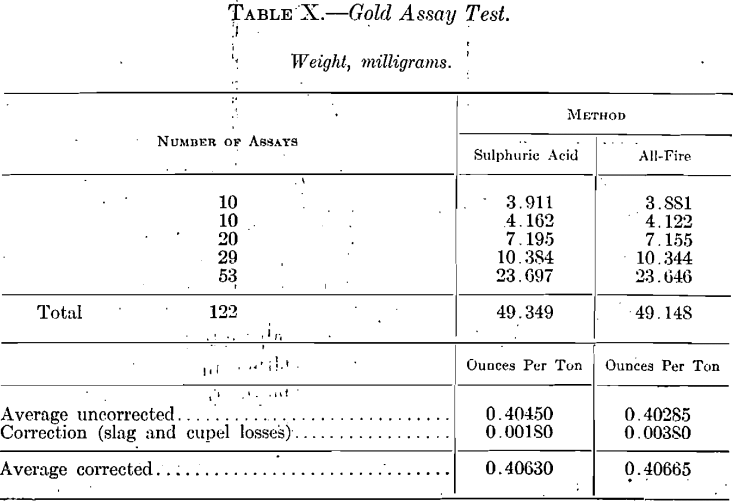

In Table X. are given probably somewhat more convincing, comparative figures for gold as determined by the once standard all-fire method

and the now adopted sulphuric acid combination method. Clearly, the figures for the all-fire method are lower than those for the sulphuric acid method when the scorification and cupellation losses are not taken into account; but when corrections are made for these losses they may justly be deemed identical for all practical and commercial purposes.

This leads to the consideration of the corrected versus the uncorrected silver and gold assays. Nearly 20 years ago Carl Stetefeldt published a paper in which he pointed out that, in assays- for silver in silver and siiver-lead ores the losses entailed in the commercial assay methods amounted to from 5 to 20 per cent. depending on the grade and composition of the ore, of which no account was taken. There can be little doubt that the silver losses in assaying hopper ores are; equal, if not greater, than those in Stetefeldt’s ores. Unless such losses are carefully deter-

mined and the proper corrections made on till materials from the mine to the refinery, the statistics of milling, smelting and refining-efficiency must be a deception; they are unable to tell us the truth on conservation. In order to understand this it must be remembered that percentage- losses in assaying are by far the lowest in the high-grade or final products of the metallurgical establishments. For an example, let us take the loss for silver in these materials at 2 per cent, and that in the ore as probably not less than 10 per cent.; accordingly, the mill receiving the ore would be charged with only 90 per cent, of the silver which it has actually received. Suppose that in its highest product it shows, by the same assay methods, a yield of 95 per cent., the apparent loss through its whole process would then be 5 per cent., while the true loss would be made up of the factors 10 + 5—2, or 13 per cent.

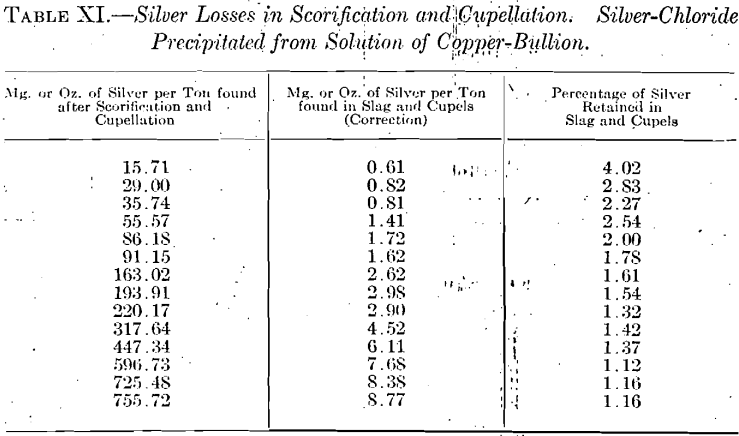

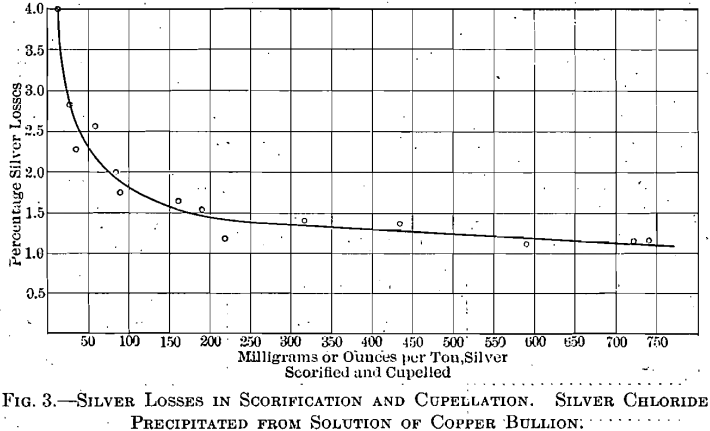

There are many data given in chemical and metallurgical literature on the assay losses of silver and gold, but Table XI., giving data on silver only, taken from actual practice in our own laboratory and derived from uniform methods, gives a wider range than anything the writer can now recall.

It clearly shows the slow increase in percentage loss toward the high-silver end, or the rapid increase of these losses toward the low-silver end of the table. Fig. 3 shows the same data plotted and the general trend illustrated by a curve. There are no corresponding data for gold available, but it may be stated that the loss percentages for that metal, in the materials and by the methods under discussion, are far smaller than for silver. A similar relation holds true as regards value losses of the two metals, which is illustrated in Table XII, the figures being taken from a full month’s run of Anaconda copper-bullion. While these values look small when considered for the single, ounce, they are of commercial importance when the great quantities produced per year are taken

Corrected assays should not only be made for commercial reasons on high-grade products, but they should be universally advocated for the sake of accuracy itself, for the establishment of correct efficiency records and true conservation statistics.

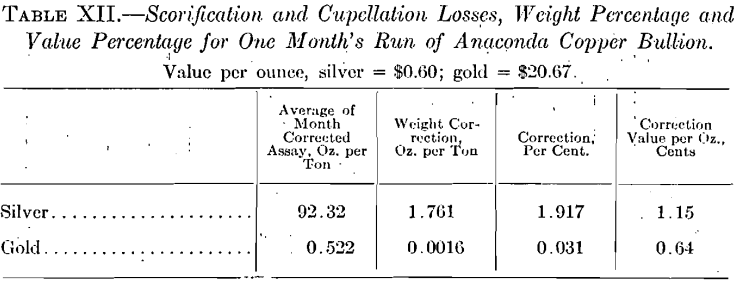

In making these assay-loss corrections for such uniform material as the Anaconda copper or that of other large producers it is perfectly permissible to collect assay slags and cupels for a whole month’s run and to apply the correction found to the individual results of the month following. The mode of operation is as follows: The slag and cupels are crushed in a small jaw-crusher and thoroughly mixed. The whole or an aliquot part may be taken for the reduction-fusion in G crucibles, each of which is charged, in grains, with 200-slag and cupels, 70 borax, 70 bicarbonate of sodium and 10 flour. The resulting lead buttons are scorified and cupeled; the resulting silver-gold buttons by weighing and parting yield the corrections sought.

In order to obtain full recovery of the silver and gold from slags and cupels it is necessary to reduce practically all the lead from each crucible charge. For this 10 g. of flour with a salt cover suffice; the salt cover serves no other purpose than the prevention of combustion of the reducer.

Inquiry into the absolute accuracy of the heretofore-described assay methods naturally suggests itself. We have already seen the slag and cupel losses for silver and gold and have noted that corrections are made for them. There are, however, other losses, such as by volatilization, by solution of the silver chloride, and in mechanical ways; their values are

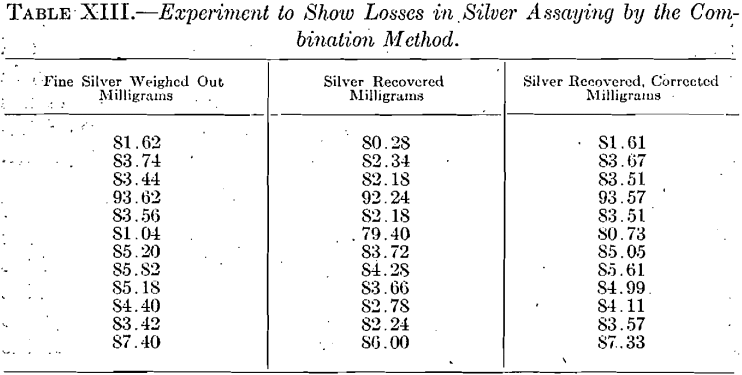

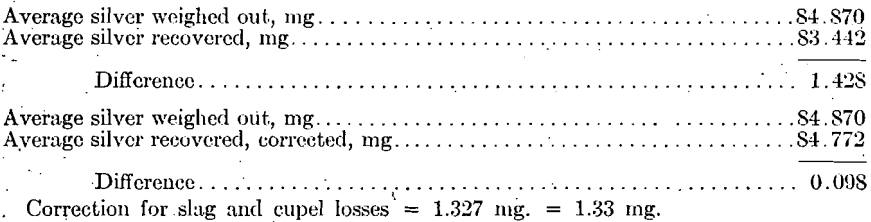

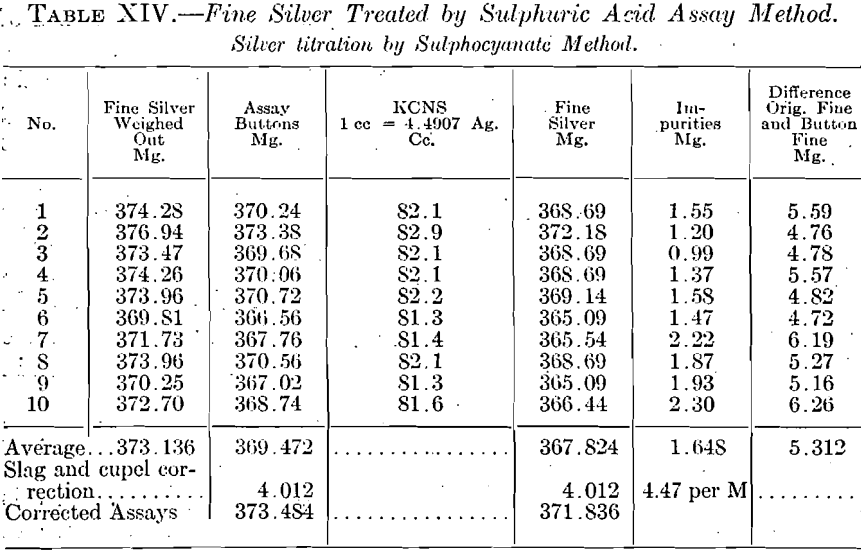

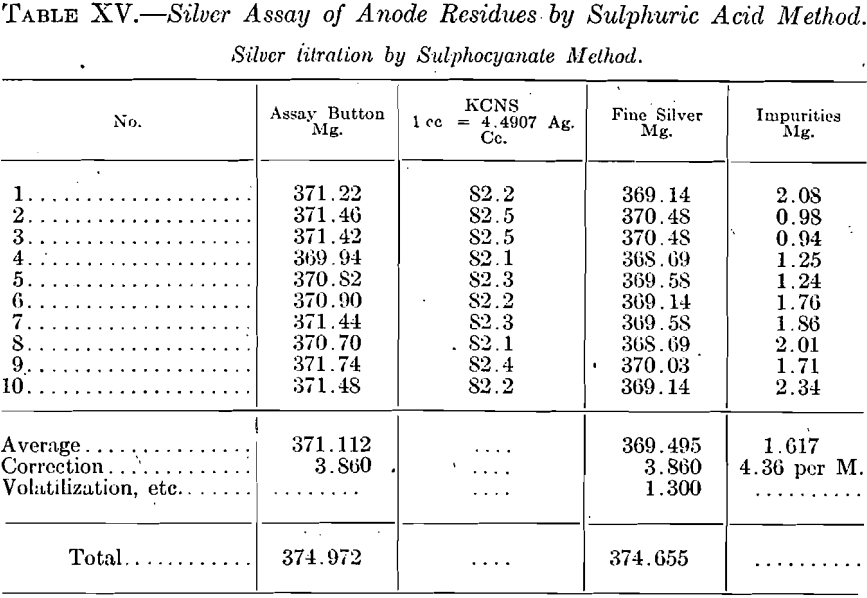

of very difficult determination by direct methods. These losses are entirely or in part offset by the amount of impurities which remain with the buttons and are weighed as precious metals. It is a simple matter to analyze a sufficient number of silver buttons. Thirty grams of these, each weighing between 80 and 100 mg., were found to contain 0.16 per cent, lead and 0.15 per cent, bismuth, total 0.31 per cent., or the buttons to be of a fineness of 996.9. Table XIII. shows a test in which fine silver was subjected to exactly the same process as the silver in the assay of copper bullion, i. e., the fine silver was dissolved in a copper solution free from silver and precipitated as chloride, etc. It will be seen that the final and corrected result shows a small deficit, amounting to 0.098 oz. per ton, or to 0.12 per cent, of the total silver. More extended tests were undertaken with more silver and in comparison with higher grade materials, anode residues or slimes. Here, too, the fine silver was subjected to the same treatment as the slimes, a sulphuric acid combination assay, and through the furnace process slimes and silver alternated in position, in scorifiers as well as in cupels. One-tenth of an assay ton of slimes was taken; all of the same sample. The fineness of the buttons was determined by titration by Volhard’s method, with potassium sulphocyanate. The results of such a test are given in Tables XIV. and XV.

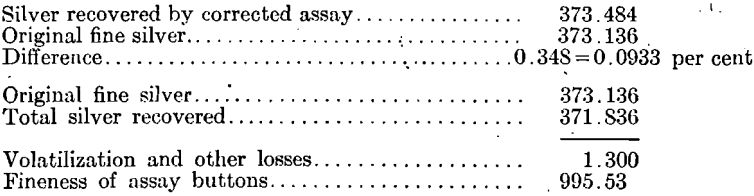

In these tables it will be observed that the large silver buttons are of slightly lower fineness than that which was given for those of lighter weight. Of chief interest is the fact, that when to the fine silver of the assay buttons of the slimes is added the slag and cupel correction and the volatilization and miscellaneous loss correction, as determined by the assay treatment of fine silver, the results correspond very closely to the usual results when the slag and cupel correction is added to the assay button of the slimes. Repeated tests confirmed this and the conclusion follows, that impurities in assay buttons and volatilization and miscellaneous losses balance each other. It follows that the assay of anode residues for silver by this assay method is correct in every case to within about plus or minus 0.1 per cent, of the total silver, an accuracy which could hardly be attained by any other chemical method. Of course, this degree of accuracy is only obtained with a sufficient number of determinations, averaged to one result, in our case 10, with 0.1 assay ton each of the material.

The contract assay methods for such materials are still of an archaic kind, of the all-fire nature, elastic beyond reason, in which results differing several per cent. are often obtained. It is to be hoped that concise methods will soon take the place of the old.

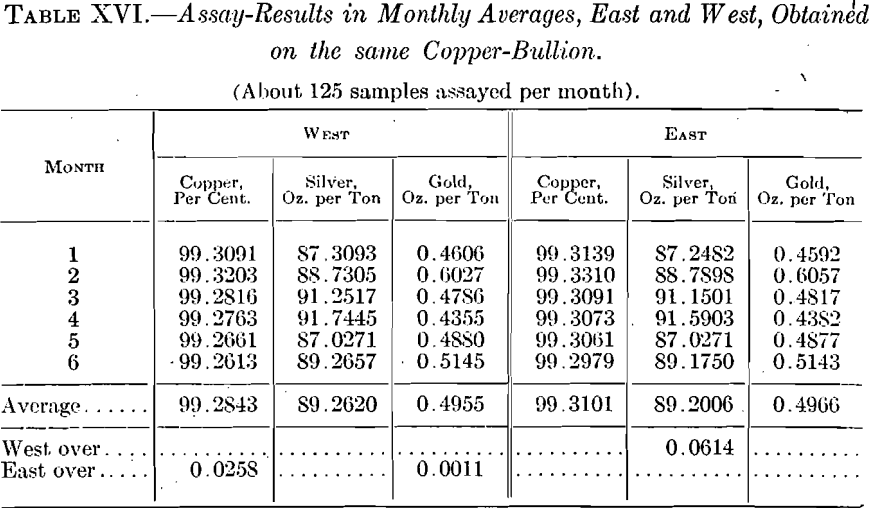

For the western (smeltery) and the eastern (refinery) end of the Anaconda Company, sampling has been established on a scientific basis and the most accurate assay methods are employed to determine the values of the copper-bullion shipped from one to the other. Any inaccuracy in sampling will offset the accuracy of analysis, or vice versa; an equal degree of accuracy is requisite for both. The concordance of results obtained in monthly averages at the two places is illustrated in Table XVI.

The data given in this paper were, in the greater part, determined and accumulated in the interest of the Anaconda Copper Mining Co., in its laboratory at the Raritan Copper Works, Perth Amboy, N. J. In this work the laboratory staff must naturally have contributed its share and the writer herewith especially acknowledges the services of K. W. McComas and W. L. Raup, Jr.

Difference………………………………0.317 = 0.106 per cent.

Fineness of assay buttons, 995.64.