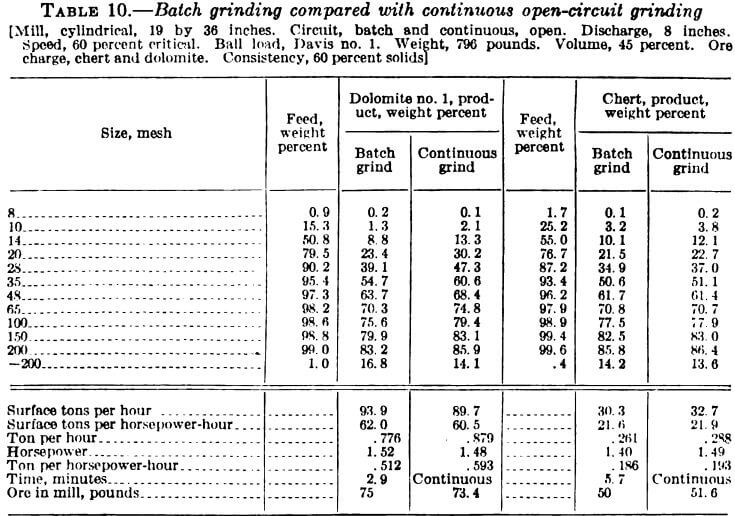

When the amount of ore in the mills was the same, no appreciable difference between batch and continuous open-circuit ball-mill grinding was found. This should be so, because the progression in particle size for the duration of a batch run would be expected to be the same as the progression from the feed to the discharge ends in a continuous run. Table 10 illustrates the marked similarity of the two wet-grinding methods. It includes tests with both chert and dolomite.

In examining the batch product of the dolomite, allowance should be made for the poor adjustment of the time period in the batch grind. The time should have been about 2.5 instead of 2.9 minutes. In other words, the tons per horsepower-hour should have been greater, so that the reduction would have been somewhat less. In continuous work the rate of feed and size of discharge were adjusted so that each pair of tests had about the same amount of ore in the mill. If the pulp in the continuous tests had been extremely dilute, or if the continuous run had been in closed circuit, the products would have been different from the batch grind.

When batch tests and continuous open-circuit tests are made with due consideration of fundamentals, the respective products may be expected to be identical.