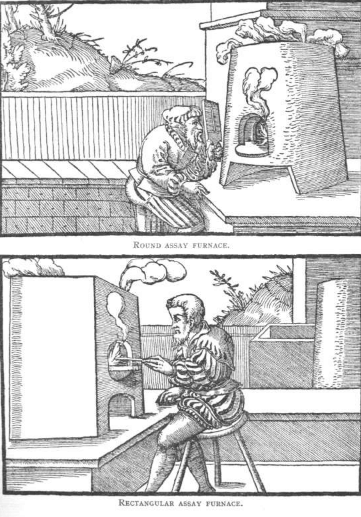

Wood burning assay furnaces are made with single and double muffles and are much like the soft coal furnaces except that a larger firebox and grate are used. Wood is usually sawed in 2-foot lengths and with dry wood the muffle may be easily heated sufficiently for assaying. Hard wood is much to be preferred as it does not bum out as rapidly, but almost any kind of dry wood may be used.

The large firebox and the grate, which is set about 8 inches below the bottom of the fire-door are the principal distinguishing characteristics of a wood-burning assay furnace.

Last fall, having a number of ore samples from mine-development work carried on in spite of the “Revolution,” I was forced to do my own assaying again, after a lapse of many years. This gave me an opportunity to build a furnace for crucible assaying, using wood for fuel, along lines which had been developing in my mind since the time 20 years ago, when as general factotum at a little mining camp in western Chihuahua, Mexico, I had converted a crucible charcoal furnace into one using the reverberatory principle.

Wood-burning furnaces have been described in technical literature, but I believe the present application will prove helpful to those of the profession who are working in out-of-the-way places. The furnace is shown in detail in Figs. 1, 2 and 3.

Remembering the trouble caused by stoking my first charcoal furnace too heavily, I fired this one with but a few sticks of wood at a time. By this method I could run out a charge of 12 crucibles in 30 to 35 min., using 50 sticks of ordinary stove wood. Later I fill up the firebox, holding about 40 sticks, get everything ready, put the crucibles into the melting chamber and “fire up.” Just as soon as the fire is well started the draft door is closed and the furnace allowed to heat up slowly for 5 min. Then the draft is opened (the door to the ash-pit) and the fire allowed to roar, which it does. In 20 min. from the time the fire is lighted the fire door is opened, the fire stirred along the grates, and 5 or 6 more sticks of wood thrown in. In 25 min. from the start, the draft is closed again, the cover of the melting chamber pushed back and the charges poured. The melts will be found to be perfect, and the crucibles to pour absolutely clean, if everything has gone right, as will usually be the case. A new charge may be put in, and fired with 8 to 10 sticks of wood at a time, and be ready to pour within 20 min.; but it is just as well to leave the crucibles in the melting chamber a full 25 min.

By using 10 sticks of wood to start the fire and adding 5 sticks as often as needed, which will be as soon as the last sticks fed in are in perfect combustion, the smelting can be completed in from 30 to 35 min., using from 35 to 40 sticks of wood. I consider this to be the best method of stoking.

I use the Battersea No. 10 crucible, having no others, but the base of these is so small that they are very apt to tip over in the strong draft; and often two and three will go over at a time, unless great care is used in setting them on the hearth. This precludes the putting in of a second charge, as, due to the heat, the crucibles cannot be set with the necessary care.

The crucible to use with this furnace, whatever size be used, is the wide-based, flower-pot shaped crucible made by American manufacturers. With this class of crucible one can run as many charges as he cares to without the fear of a mishap of any nature.

In “drawing,” one asbestos glove is necessary; and, when nails are used, they can be withdrawn easily with the cupel tongs.

When I built my furnace, I built at its back, and leading into the same chimney, an ordinary charcoal, muffle furnace. Later, as charcoal was hard to get, I decided to try wood with it also, and altered it to the shape shown in the drawing. It works splendidly, and once heated up, is easy to keep hot.

When firing the muffle furnace, burning charcoal, I noticed, when the crucible furnace was in use, that the flame from this passed up the chimney beyond the top of the muffle flue. I mentioned this to R. C. Sanford, of the Palmarito mine, who was examining my plant, and he suggested putting the muffle in the chimney. I could not do this very well, but he did, when he built a furnace, after the plans I loaned him.

How well the furnace works, and the success attained by putting the muffle in the chimney of the crucible furnace can be judged from the following extract from a letter Mr. Sanford wrote me recently.

“On my return to Palmarito I at once started to build a furnace, and it has been in operation for some time now, and is a success in every way. I took great care in following the inside dimensions in your plans.

“In place of building a separate furnace for the muffle, I put the muffle in the chimney of the crucible furnace (as an experiment), 34 in. from the floor of the furnace and 1½ in. from the chimney wall. While the muffle is placed higher than need be, it does perfect work.

“Mr. Price, of the Potrero mine, has also built a furnace from your plans and has set his muffle somewhat lower. When I last saw him he had not started using his furnace, so I do not know what success he has had with it.

“The furnace has certainly been a wonderful help at the present time with gasolene so scarce and high priced; but without doubt we shall continue to use it even when gasoline is more plentiful and cheaper. It is as quick, is cheaper, and does the work as well as a gasolene furnace, so it is to our advantage to continue using it.

“You are to be congratulated on your success in devising it.”

Since receiving this letter I have seen Mr. Price, and he was as enthusiastic in the praise of the wood-burning furnace as Mr. Sanford.

The only disadvantage of putting the muffle in the chimney is that it puts the mouth of the muffle rather low for comfortable work, as the floor should not be over 24 in. below the top, A, of the melting chamber, which would leave the muffle about 44 in. above the floor.

The whole furnace can be constructed of ordinary brick and mud mortar, but the arches, and all parts exposed to the greatest heat, should be lined with fire brick.

The chimney, built as shown, need not be over 12 ft. high; and if a damper were put in near the top it would do away with the need of a door to the ash pit. But, as there is no heat at this place, a piece of 2-in. plank, wide enough and high enough to cover the opening, is all that-is needed, although a well-fitting door looks better and is more convenient.

The top to the melting chamber, A, should be a solid fire-brick piece 22 in. square and 1½ in. thick; but a piece of asbestos board 2 by 22 by 22 in. would do; or a piece of sheet steel ½ in. thick by 22 in. square.

I use a piece of cast iron 1 in. thick, but it requires the aid of a helper to move, as it weighs over 125 lb. This heats, but not excessively, and makes a splendid place to warm up the molds.

The grate bars are shown longitudinally but may be placed crossways, and where regular grates are not to be had, 1-in. round iron cut in 18-in. lengths and 1 in. at each end flattened to 1½ in. wide, will answer capitally.

An ordinary piece of 1/8-in. sheet steel makes a good door, and this may be bolted to a 4-in. post set 2 ft. in the ground so that the door makes a snug fit. Unless one has regular furnace fronts, this class of door is the very best that can be devised.

The furnace shown will hold sixteen 30-g. crucibles, but 12 work to perfection if set as indicated in the plan, and in the order shown, “drawing” from the side D and pouring No. 1 first, and so on to the end. This keeps the last crucible in the greatest heat until poured.

Should any of the charges seem to be slightly frozen, if the crucible be given a whirling motion in the flame for a moment, it will liquefy and pour readily, as a rule.

The top of the furnace, over, the firebox, makes a handy place upon which to set the molds to receive the pour. A top finish of cement prepares it perfectly for this purpose.

This is a furnace that will give good results always, whether built with the utmost refinements of the art or as crudely as may be permitted.

The muffle, whether set in the furnace separately or in the chimney of the crucible furnace, should not be of a size less than 6½ by 10 by 16 in., outside measurements, and as nothing ever hits it, it will last for months, if care be taken with the bottom.

No draft is needed, as the heat can be controlled by stoking.