Table of Contents

Objective

Reduce the number of conveyor-related accidents in the mining industry by providing recommendations for effective operation of conveyor belt cleaning systems.

The Problem

Troughed belt conveyors provide effective and efficient materials transport and their use has increased throughout the mining industry. Carryback, the spillage that accumulates under the belt, is a problem even with belt cleaning systems installed. Mining personnel arc exposed to safely and health hazards as they attempt to clean up this spillage.

Approach

To investigate the influence of metal-segmented-blade belt cleaners on the amount of carryback spillage, the Bureau identified and tested the following parameters:

- amount of pressure applied to the cleaner blades,

- friction between the blades and conveyor belt, and

- wear rates of different metal blades.

The test parameters were quantified by recording the amount of carryback material passing the metal cleaner blades and the weight loss of the blades. The dala collected were used to identify the following critical operational parameters of a segmented-blade conveyor cleaner system: (1) the existence of an optimal operating pressure for the conveyor and cleaning systems and (2) elimination of recessed patterns on the working side of the conveyor bell.

Test Facility

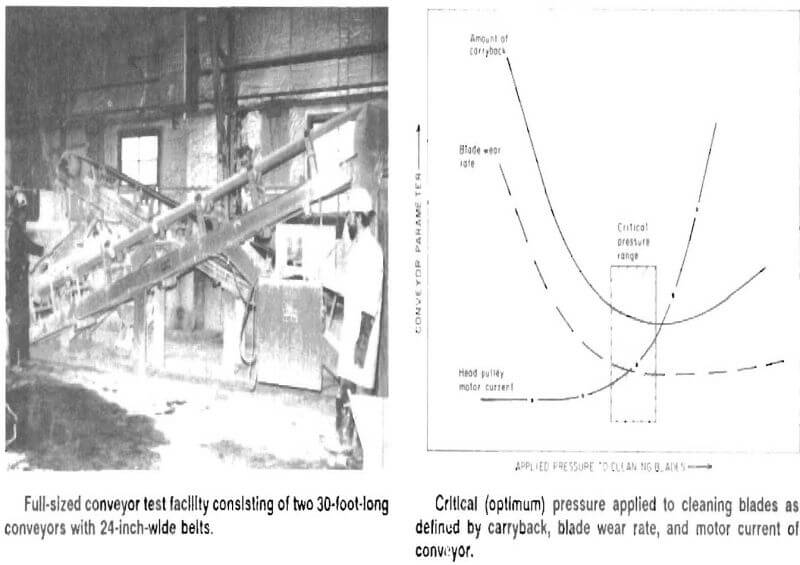

A full-sized conveyor test facility was constructed to gather the data, It consists of two 30-foot-long conveyors with 24-inch-wide belts and 24-inch-diameter pulleys. A special test fixture bracket was designed to hold test blades perpendicular to the rubber belt with air-actuated cylinders. The recycling conveyor was fitted with a large storage hopper to provide a constant sand lime slurry mixture to the test runs.

Investigation Results

Carryback rate and blade wear rate versus pressure curves indicate the existence of a critical pressure range. The critical pressure range for the test conveyor system was 11 to 14 psi applied to each cleaner blade. Above 14 psi no significant decrease in carryback was observed during the 8- to 24-hour test runs. Blade wear rate did not increase above this pressure hut the conveyor belt-blade friction increased. The conveyor head pulley drive motor current increased 26% when the pressure applied to the blades was increased from 14 to 20 psi.

Nonuniform wear patterns were observed in the edge of all the cleaning blades during the 8- to 24-hour test runs. The channels or grooves worn into the blade edges were from abrasion and erosion caused by the sand particles and the slurry mass. Once the grooves were worn into the blades, increasing the blade-to-bell contact pressure did not eliminate the carryback. Metal blades (¼ by 6 by 2 inches) made from mild stainless, alloy, and tool steel were tested. The Rockwell C hardness of the blades ranged from 11 to 50. The wear rates decreased with increasing hardness, but eventually the nonuniform wear pattern of peaks and valleys became visible and the carryback amount increased to 5 to 10 grams per square foot. Wear rates varied from 1 to 6 mils per year for the test blades.

Company logos or other patterns recessed into the conveyor belt working side allowed material to be carried between the blade and bell, which accelerated blade wear by 55% to 60%. The wear pattern of the metal blade edge will be characteristic of the recessed pattern filled with the conveyed material in the belt.

This study showed the existence of a critical operating pressure applied to belt cleaning blades for maximum cleaning and minimum wear of the blades and belt. Cleaner blade service life can be lengthened by using metal with greater hardness. All advantages can be negated with any defect on the belt surface that allows additional carryback. This additional carryback will shorten the cleaning system’s service life and increase maintenance around operating conveyors.