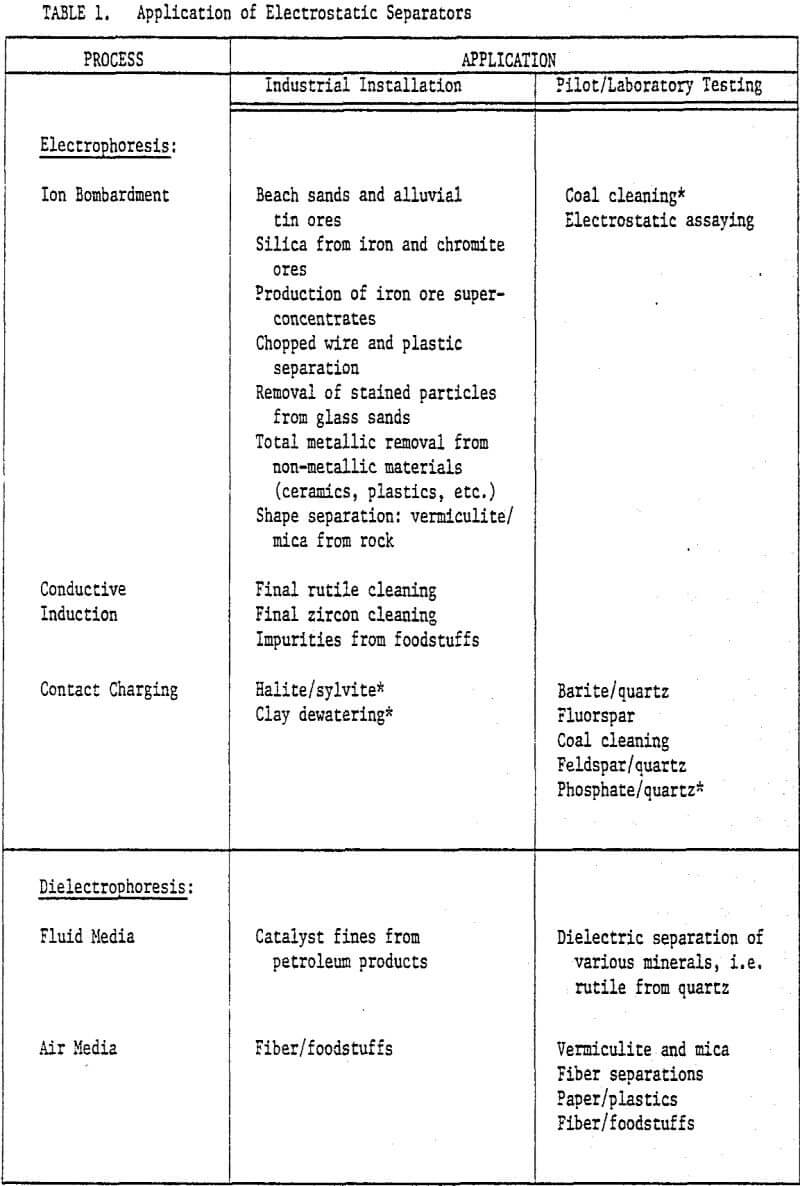

Electrostatic separation is one of the most misunderstood physical processes used to beneficiate minerals. Nonetheless, millions of tons of titanium ores, iron ores and other minerals are processed every year economically, efficiently and safely. Over the past ten years major advances in electrostatic separation and its application have occurred. New processes include dewatering clay slurries, separating halite and sylvite, and shape separation of vermiculite and gangue minerals.

Electrophoresis

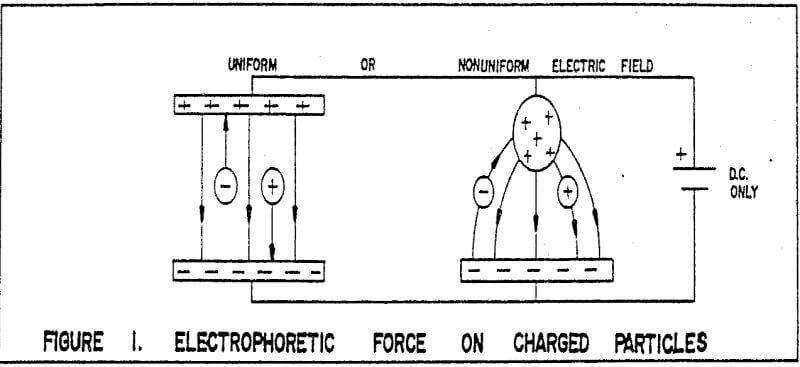

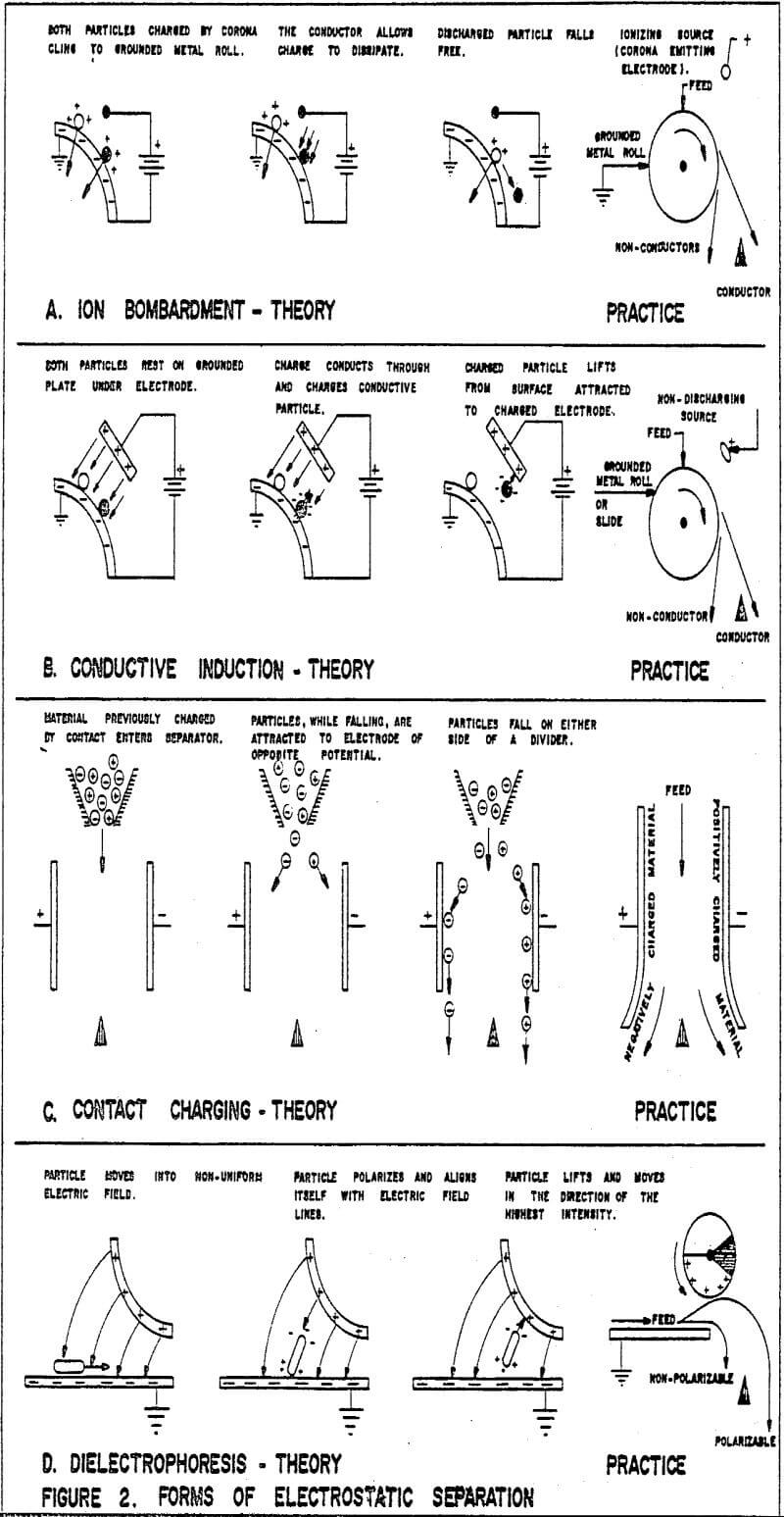

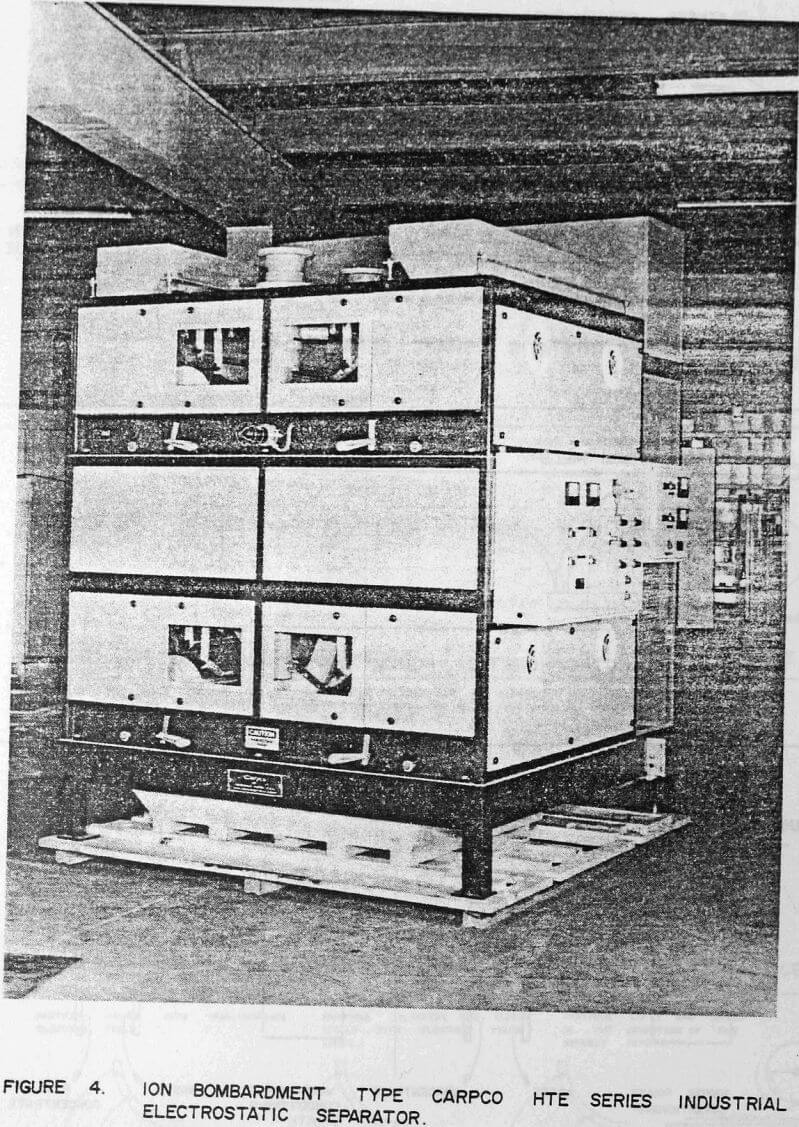

Electrophoresis is the motion of a charged body or particle under the influence of an electric field. Simply put, like charges repel and unlike charges attract one another. An electrostatic mineral separation uses electrophoresis when the force acting on a particle is due to the interaction of an electric field and a charged particle. The electric field can either be that from a high voltage source or from the charged particle’s own electric field. Particle charging can occur in three forms — ion bombardment, conductive induction or contact charging.

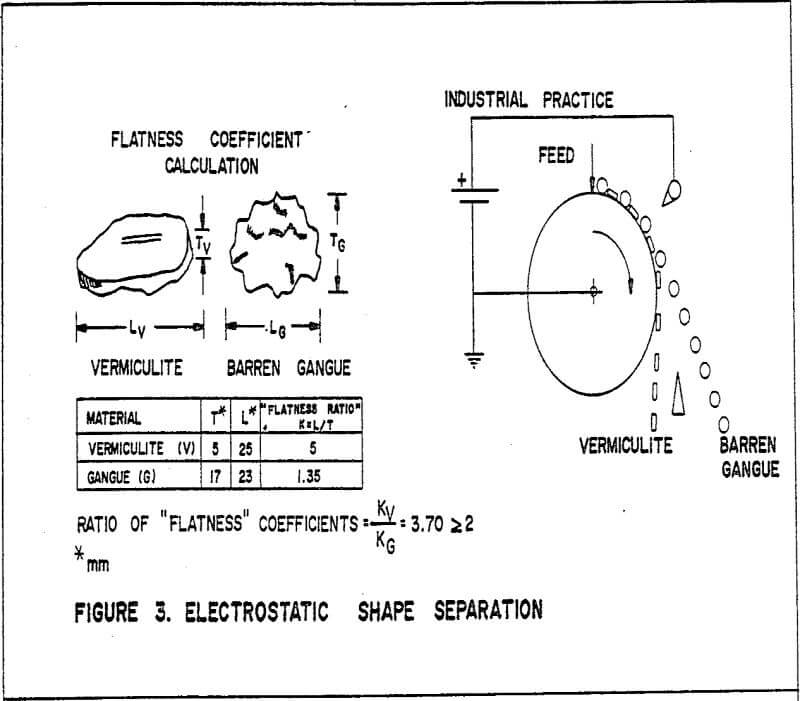

Shape separation is a new form of ion bombardment separation. Unlike conventional ion bombardment in which separation is based on conductivity, shape separation uses advanced roll construction and controlled charging techniques to separate materials based on the particle’s shape and density without consideration to the constituents inherent conductivities. The separation characteristics of large particles can be determined by the simple calculation of the “flatness” coefficient.

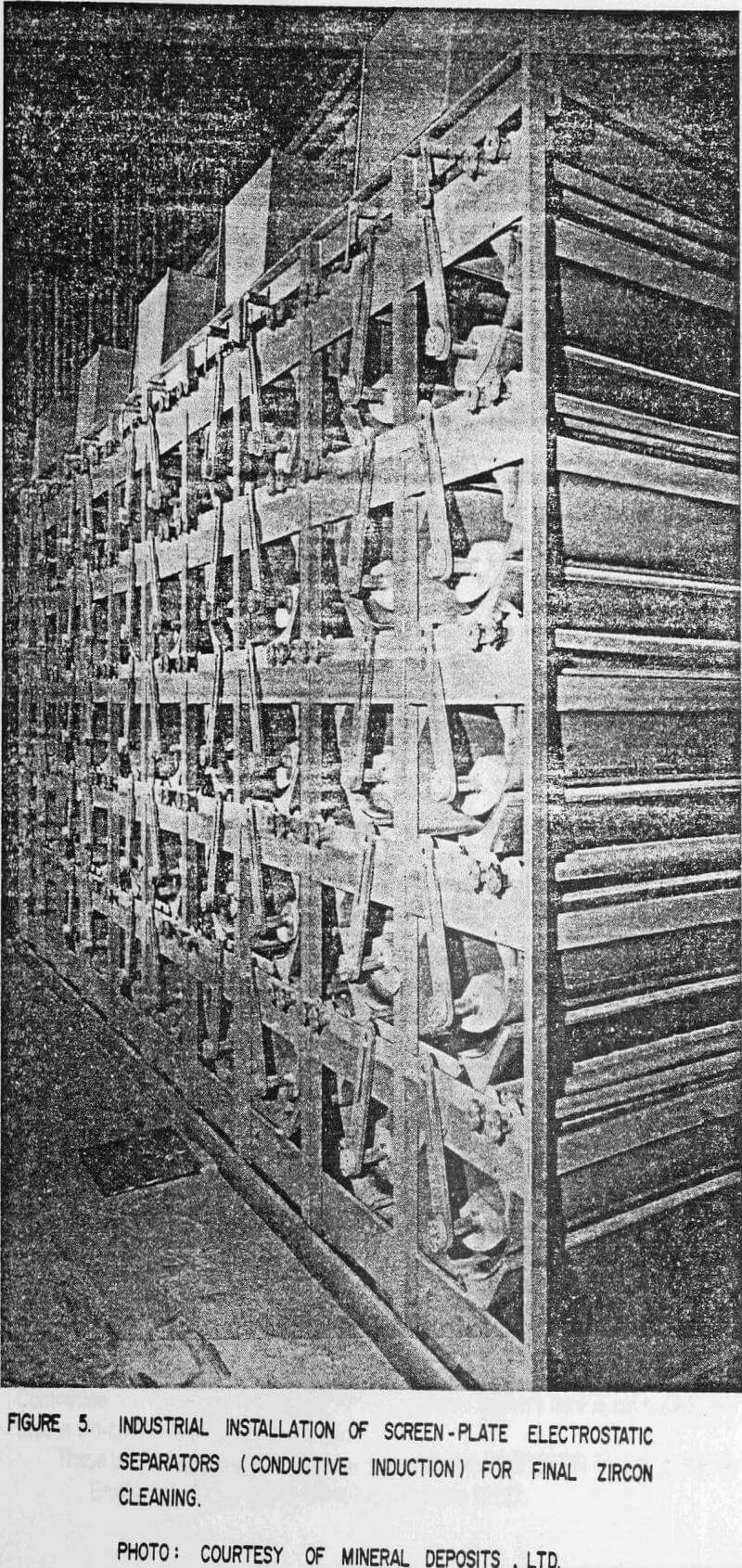

Conductive induction is similar to that of ion bombardment in that large differences in particle conductivity are needed to effectively separate materials. Particle charging is less; therefore, the forces generated by this type of separation are generally weaker than that of ion bombardment, and per-stage efficiency is decreased.

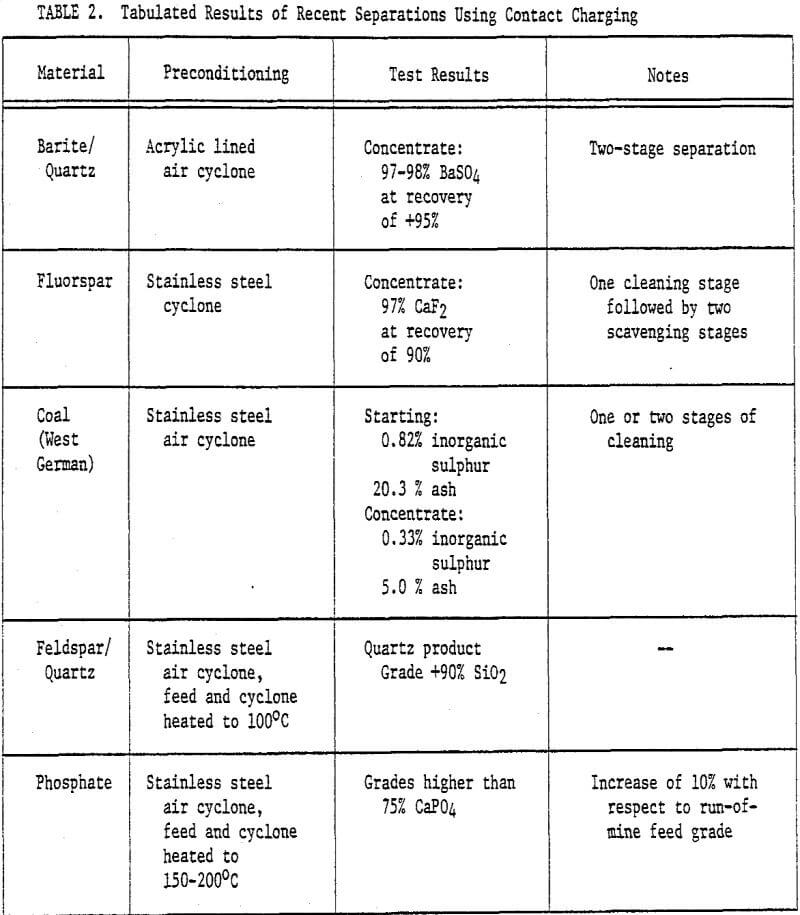

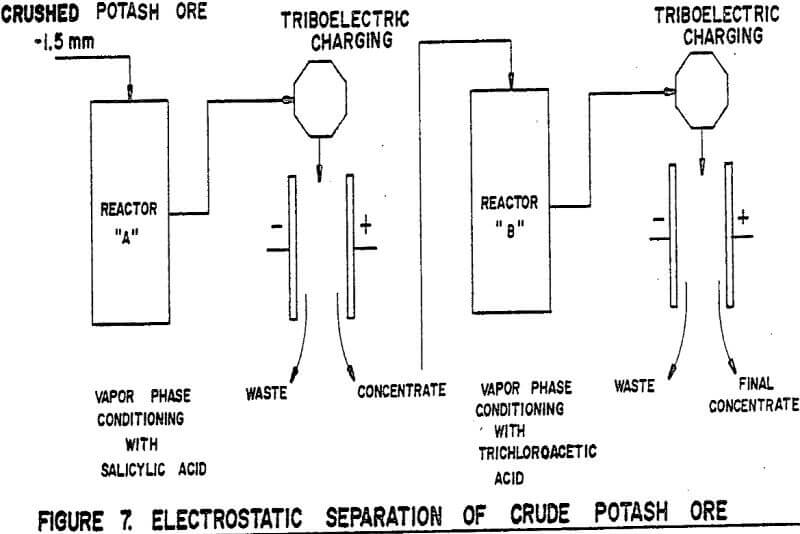

Contact electrification is one of the oldest methods used to separate nonconductive minerals electrostatically. Contact charging occurs when two minerals of different composition are repeatedly brought into contact with one another. A rule of thumb often used for predicting the sign of the surface charge resulting from contact electrification is Cohen’s rule, which states that “when two dielectric materials are contacted and separated, the material with the higher dielectric constant becomes positively charged.”

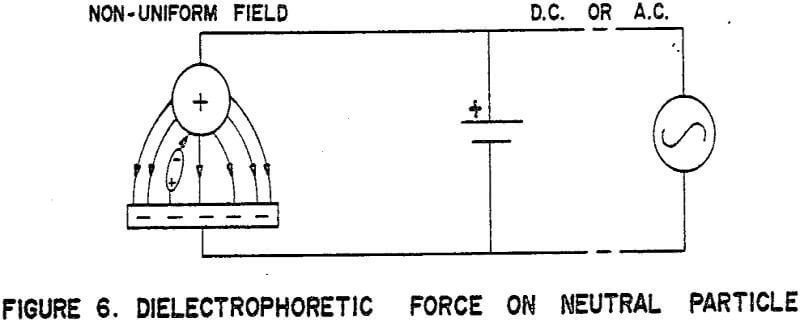

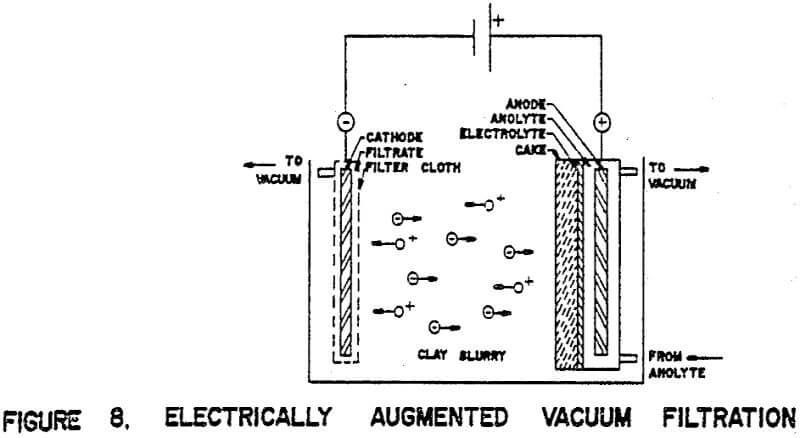

Dielectrophoresis is the movement of neutral particles in a non-uniform electric field. Dielectrophoresis differs from electrophoresis in that:

Dielectrophoresis produces motion of bodies suspended in a fluid medium. The direction of that motion is independent of the sign of the field. Accordingly, either a.c. or d.c. fields can be used. Electrophoresis produces a motion of the suspended particle in which the direction of the resultant path depends upon both the sign of the charge on the particle and upon the sign of the field direction. Reversal of the field reverses the direction of travel.

Electrophoretic Applications

Minerals: One of the largest ongoing ion bombardment electrostatic applications is at Wabush Mines in Labrador, Canada. This 1000 tph installation uses a two-stage circuit (rougher— scavenger) equipped with high-tension roll separators to reduce the silica content of a wet gravity concentrate from 6.5% down to 2.5% SiO2 at yields of 92%. This hard rock iron ore plant incorporated the first major use of electrostatic separation in minerals outside the beach sands industry.

Electronic Scrap: With the rapid growth of integrated circuit technology, vast amounts of electronic scrap have been generated from production and assembly operations. Significant amounts of precious metals such as gold and silver are often incorporated as part of the design of integrated circuits or printed circuit board manufacture.

Middling circuit — Excessive fines are generated and lost when fine, liberated wire is regranulated. These values can be recovered via electrostatic separation, leaving unliberated particles for rechopping.

Plastics recovery — As the value of petroleum and plastics made from it increases, so will the need to recycle these materials. Thermosetting plastics such as nylon, PVC and polyethylene can be recovered from chopped wire and cable for reuse.

Electrostatic Assaying: A roll-type electrostatic separator with modifications has been successfully developed as a control technique to effect the removal of trace amounts of metallic particles from large quantities of granular nonconductive materials.

Typical Size:

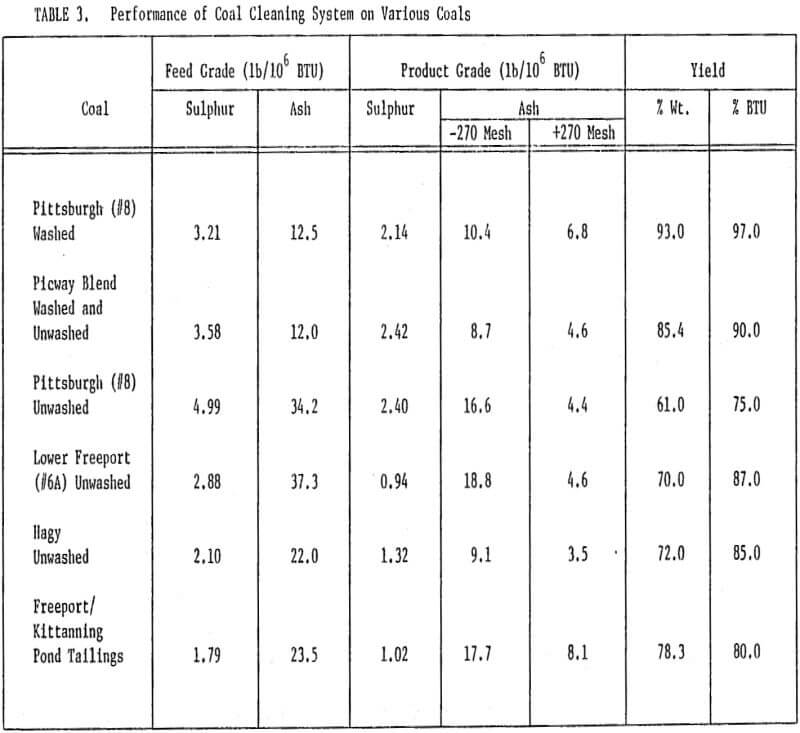

Coal: Recently a new process has been developed for the pretreatment and electrostatic separation of coal from inorganic sulphur (pyrite) and ash. Pilot plant and laboratory work have been performed with good results. The process is, reportedly, to be used at the power plant where the coal will be pulverized, pretreated, separated electrostatically and the concentrate burned as fuel.

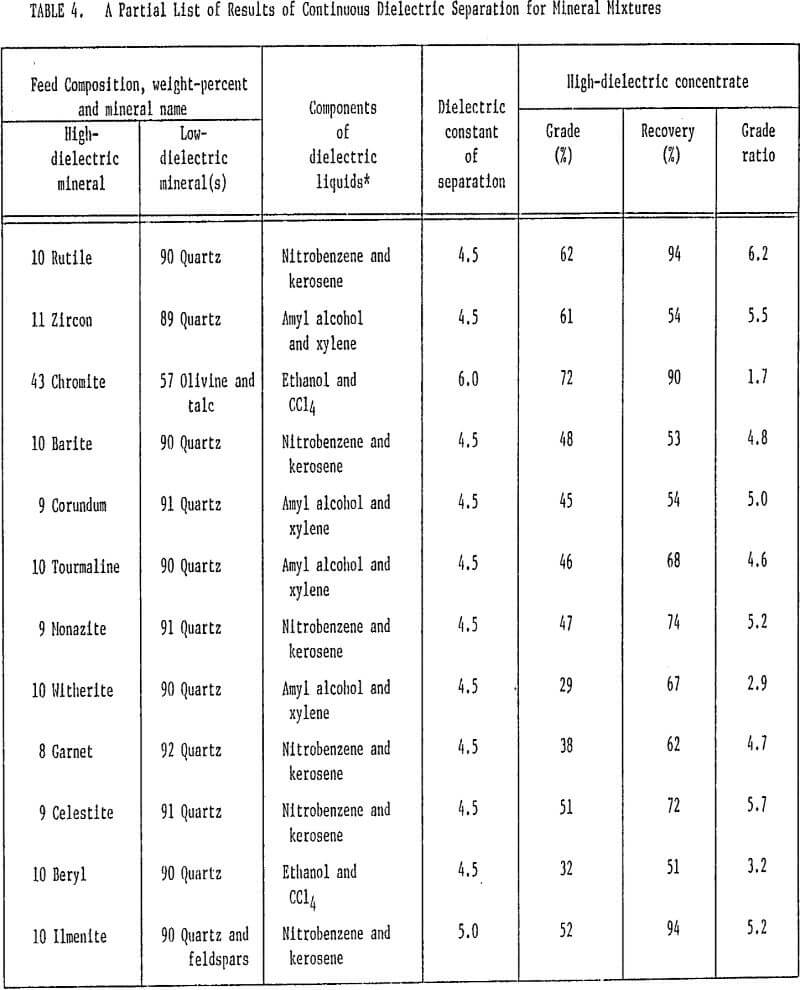

Dielectrophoretic Applications

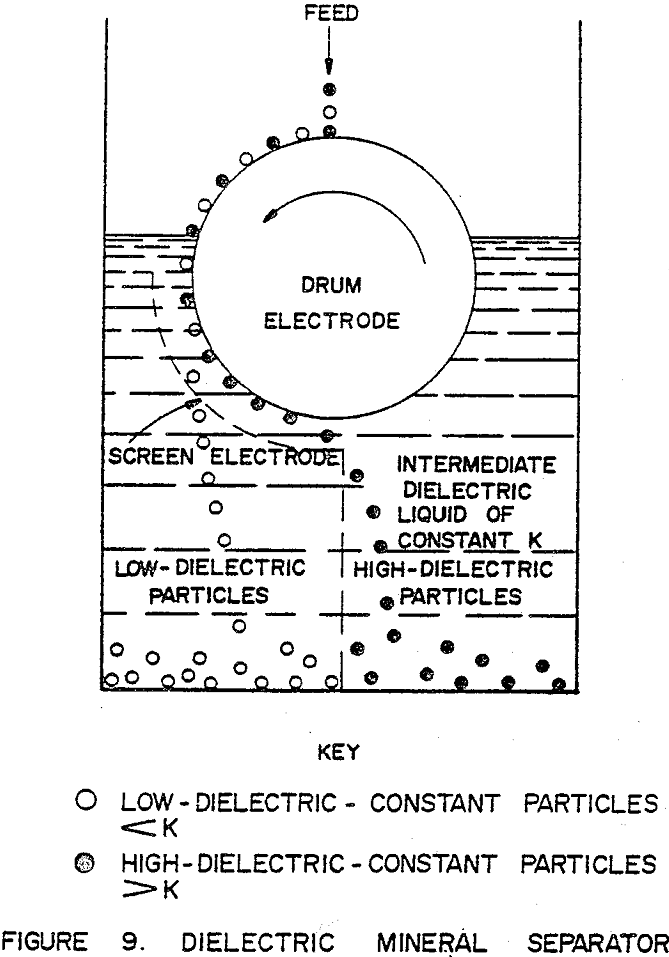

The process uses a drum with fine wires placed along its surface, parallel to its axis. A screen electrode is in solution beneath the drum, and an a.c. potential is placed across the electrode and drum assembly. Particles of a higher dielectric constant are fed onto and attracted to the region of high electric field gradient (the wires) on the drum’s surface. Lower dielectric constant material is repelled to a region of low field gradient by an intermediate dielectric fluid and falls through the screen electrode.