Table of Contents

Receded Disk Impellers

Impellers for the “Sub-A” Flotation Machine are built in two types with corresponding wearing plates:

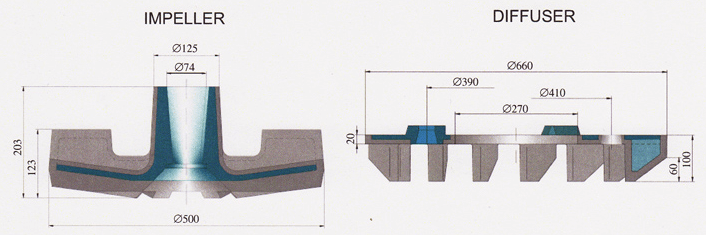

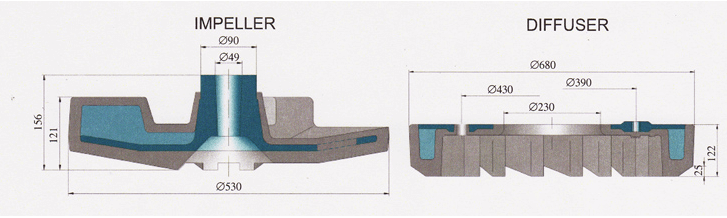

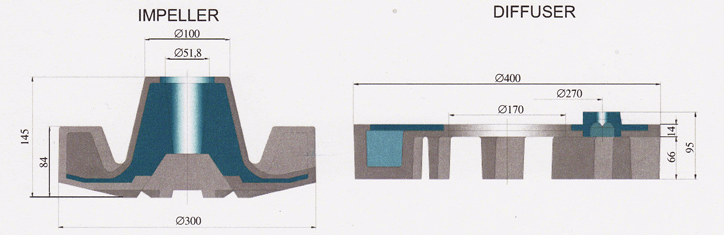

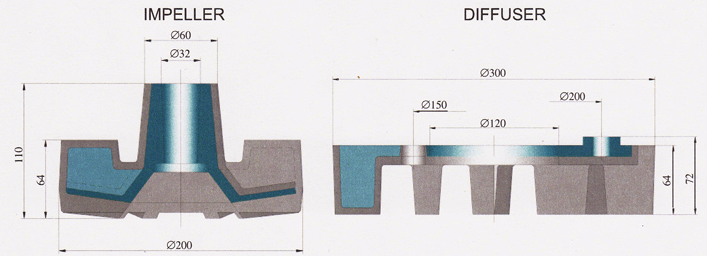

- Receded Disk Impellers and Diffuser Wearing Plates

- Conical Disk Impellers and Wearing Plates.

The receded disk impellers and diffuser wearing plates have been proved in commercial installations for many years and are one of the important developments made in the “Sub-A” Flotation Machine. The receded disk impellers and diffuser wearing plates are furnished with all machines unless otherwise specified. The advantages of these parts are as follows:

- Have permitted the increased speed of the impeller without any increase in horsepower.

- Give more aeration with an accompanying greater diffusion of air.

- At higher speeds the air is in a more finely divided state as the bubbles are smaller, and the added aeration results in a deeper froth column.

- Requires less operating attention, particularly toward the end of the machine with a uniform active cell.

Agitation is intense in the agitation zone but elsewhere it is held at a minimum and at the same time the air is finely dispersed throughout the pulp so that the cell surface presents the appearance of a smooth and quiet blanket of froth, conducive to good flotation. Molded rubber parts are recommended due to their lighter weight, perfect balance, and longer life.

In keeping with a long established policy, it is possible to use these parts on any “Sub-A” Flotation Machine irrespective of age, without the necessity of making any major changes, thus adhering to the standard policy of “No yearly models but continually improving.

Conical Disk Impellers

The conical disk impellers and wearing plates, as illustrated, are obtainable for all sizes of machines. The conical disk impellers and wearing plates have been used in “Sub-A” Flotation Machines for many years but are rapidly being replaced by the receded disk impellers and diffusers for general purposes. Conical disk impellers are recommended for Unit Flotation Cells and applications such as treatment of dense pulp and coarse material. Diameters of all impellers have a definite relationship to cell sizes, thus insuring uniform circulation of the pulp.

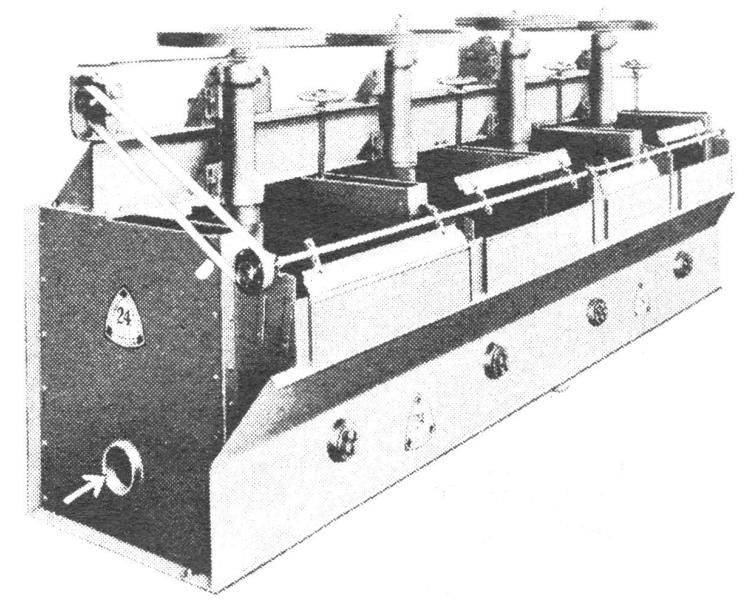

Types of Drives

The “Sub-A” was the first flotation machine to use the Multi-V-Belt Horizontal Drive, vhich has proved so successful. “Sub-A” Flotation Cells have been carefully designed to be driven either by a motor and V-belts or by V-belts to a main drive shaft. In the motor driven type the impeller shafts are driven by V-belts, sheaves, and vertical ball bearing motor. This type of motor drive is much more economical and desirable than a direct motor driven unit because it makes any speed range available and does not require a special motor shaft assembly.

The standard drive on all flotation machines of an even number of cells is one motor driving two cells through V-belt drives. If an odd number of cells is ordered, a drive which will prove most economical in first cost and provide the greatest operating efficiency will be furnished. Adjustment of belt tension is provided for in the motor mounting.

Paddleshaft Drive

The paddleshaft drive is taken generally from the last impeller shaft by means of V-belt drive to a speed reducer, which in turn drives the paddleshaft at slow speed. The No. 30 paddleshaft drive is from a gear motor. The quick removal of the mineral froth, in the form of a concentrate, increases the recovery; quick removal of this mineral froth is very important and when a high grade concentrate is desired, the rotating paddles can be regulated as desired.

Positive Pulp Level Control

Every “Sub-A” Cell is actually an individual flotation machine with its own pulp level, controlled by its weir overflow. Correct overflow normally requires this positive pulp level control in each cell even though this adjustment when once made is infrequently changed. There are three methods of regulating pulp level:

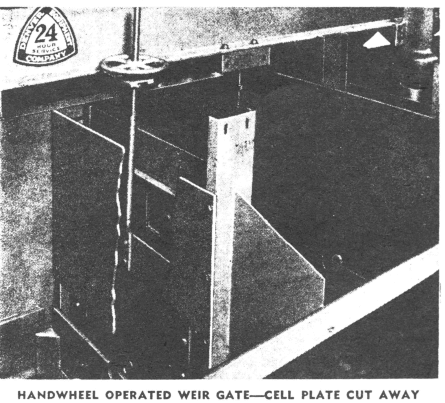

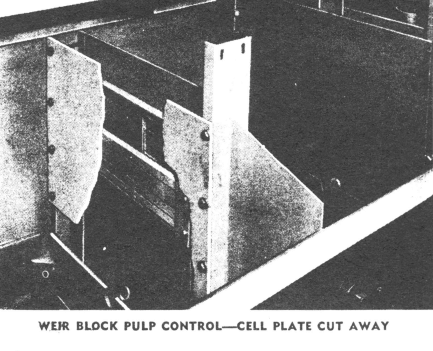

Weir Blocks, as illustrated, slide easily into place at the weir, and consist of wood slats held down by means of a steel wearing bar. On the smaller machines, especially, adjustment by this means is easy as the weir is readily accessible. Actual plant practice shows in the normal circuit that it is not necessary to change the pulp level frequently. Handwheel operated weir gates can be provided, as illustrated, so that changes in pulp level in each individual cell can be accomplished by turning the handwheel which is located far above the froth level. Changes in level can be made quickly and easily with minimum effort.

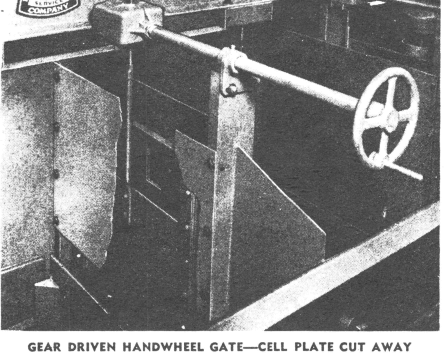

Gear driven handwheel gates, as illustrated, can be provided and are especially useful on large size flotation machines. This arrangement brings the control of the pulp level out. to the front of the machine making it unnecessary to reach over the froth lip. The use of a gear box with handwheel control reduces the effort required for raising or lowering the gate, and provides a method of quick and easy adjustment.

Interior Cell Design

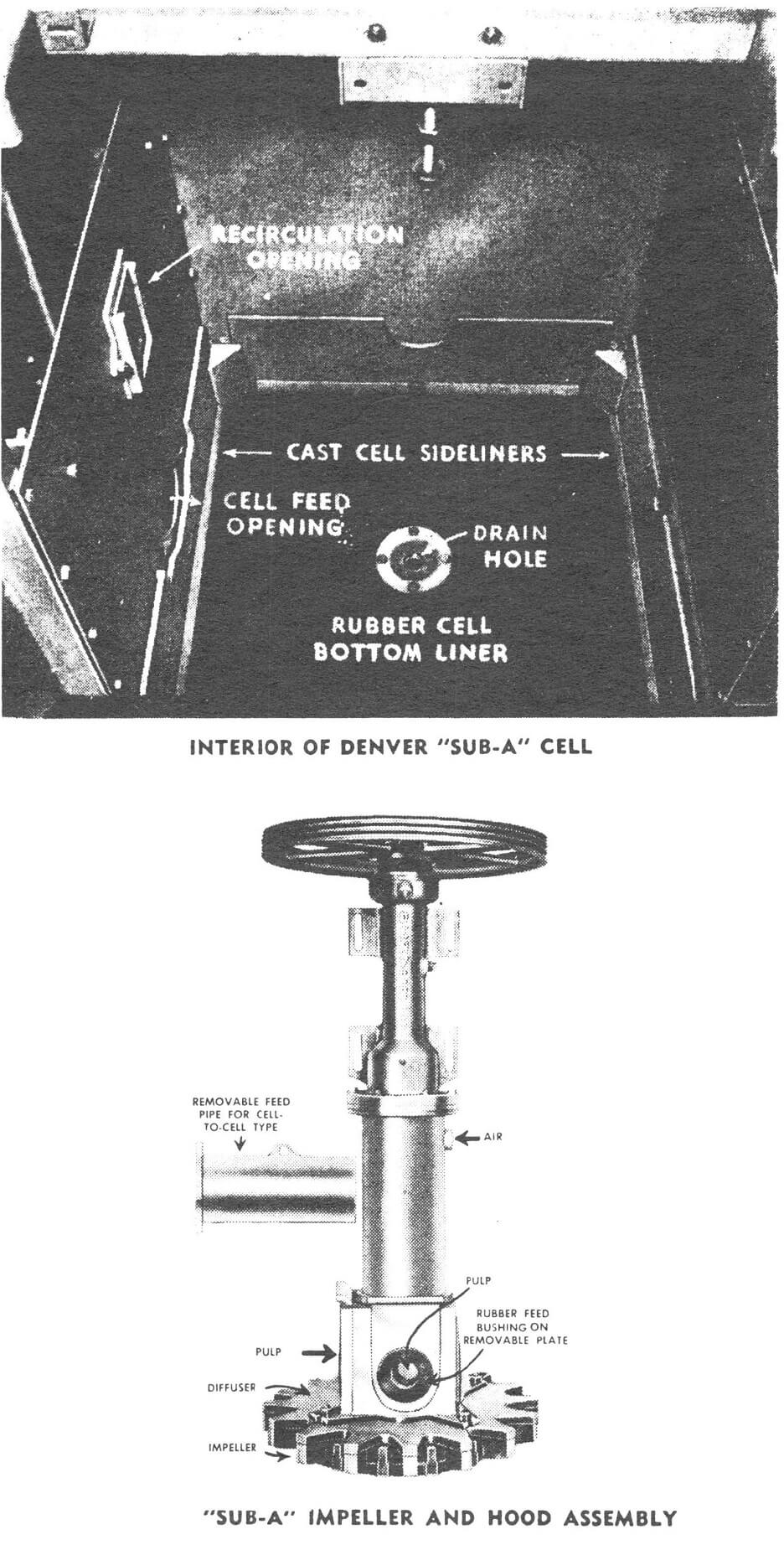

Cell liners fit easily into the cell and consist of four cast iron liners and a rubber bottom liner. This bottom liner consists of a rubber compound similar to that used on the molded rubber parts, firmly bonded to a steel backing so that it does not rip or blister. This liner is held in place at the edges by the side liners.

Cell drainage is through an easily accessible port at the back of each cell.

A small recirculation gate is provided near the top of each cell so that if desired, a portion of the pulp can be removed from the middling zone and returned to the impeller for retreatment. This recirculation feature influences the production of high grade concentrates in some cases. A gate is provided for this recirculation opening so that an adjustment of the zone and amount of recirculation can be varied.

Flotation Cells are provided with openings in the partition plates for by-passing the pulp from cell to coll without the pulp circulating through each hood feed pipe. In normal operation these partition gates are left closed; however, this arrangement is advantageous when large tonnages are fed to the flotation machine. This arrangement also allows the machine to be operated in “groups” of cells with the same positive control and circulation applied to each’ group.

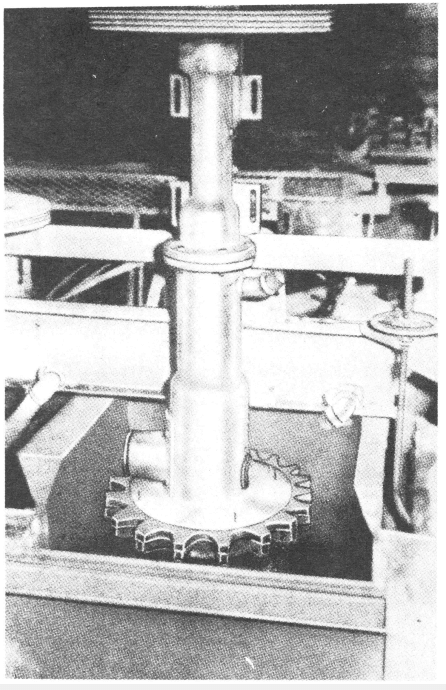

Impeller Assembly

The impeller assembly, consisting of steel shaft, totally-enclosed spindle bearings, standpipe, air-bonnet, hood, wearing plate, and impeller, fits easily into the cell as a unit. Diffuser and receded disk impellers, as illustrated, are furnished but conical disk impellers can be used if desired. The hood rests on corners of the cell side liners and is provided with keystone plug plates in front and back with recirculation openings. These recirculation opening in the plug plates can be opened, closed or bushed to small sizes as desired but in normal operation are closed. The keystone plug plate can be removed to provide an opening to the impeller for the return of middlings or feed, by means of return feed pipe which is easily placed to fit between the hood and front or back plate of the cell. Openings are provided in front of each cell for the return of middlings into any cell by gravity or these openings can be used to introduce feed into the cell if desired.

Adjustment of Impeller

Adjustment of the impeller is easily and quickly accomplished from the rear of the machine by means of the threaded rod holding the end of the spindle bearing housing. Proper adjustment of the clearance between impeller and wearing pirate is important, and is easily done by loosening the bolts holding the spindle bearing housing and raisingvor lowering the entire housing by means of the adjustment provided by this threaded rod. After the proper clearance is secured the housing is tightened in place. Guides on each bearing housing keep rotation of impeller in perfect alignment and make vertical adjustment easy.

Special Features

Each “Sub-A” Cell is provided with an air bonnet on the shaft assembly so that low pressure air may be connected if desired. To assure complete diffusion of air in the pulp an automatic seal is built in each weir casting.

When desired, a discharge may be taken at partitions on “Sub-A” Flotation Machines by reversing the weir casting and providing a special weir plate.

Feed may enter any cell of a “Sub-A” Flotation Machine, through the front or back.

The hand of the “Sub-A” may be easily changed in the field by reversing the position of the weir casting with plate and partition plate. The hood assembly is turned through 180 degrees and the feed liner is changed with the liner in the opposite segment.

Source: This article is a reproduction of an excerpt of “In the Public Domain” documents held in 911Metallurgy Corp’s private library.