Table of Contents

The speed of drilling rock has become an important factor in mining operations, while the placement of holes, kind, and quantity of explosive used are equally important. These are a function of the rock hardness and toughness. Both of these factors must be considered in compiling a table that will enable a mine operator or engineer to estimate drilling speeds in a given rock, knowing its hardness, and from its toughness, the dynamite required.

The hardness of a homogeneous rock may be defined as its resistance to a penetrating medium, such as a drill-steel bit, and toughness, its resistance to withstand rupture by the tearing apart of its minerals or parts of the same mineral. Rock hardness, as it has here been defined, is a function of the hardness of the component grains composing it, as well as grain size,

shape, arrangement, and binding minerals. Rock toughness depends on substantially the same factors, but is measured by a totally different method.

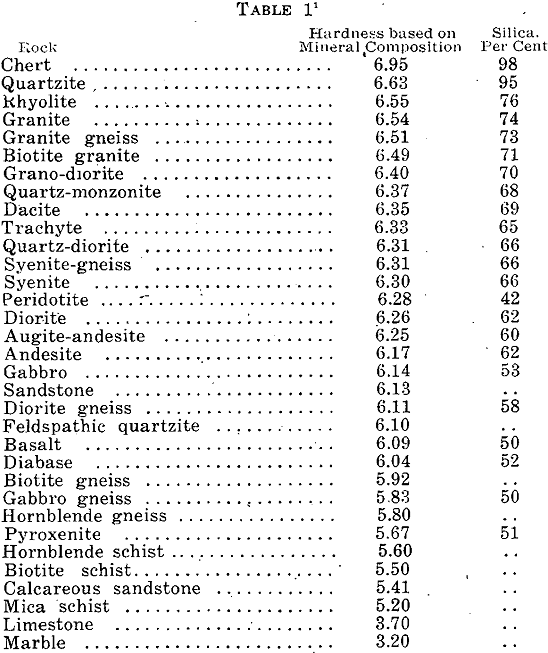

The units in which rock hardness is usually expressed are either relative values or alphabetical designations which carry no definite quantitative meaning. R. M. Raymond has suggested the measurement of composite rock hardness, based on mineral hardness as obtained by the Moh scale. This is done by multiplying the percentage of each mineral in a rock by the Moh mineral hardness and dividing by 100. These values convey a clearer conception in the minds of men interested in rock work and are the basis of the units used in Tables 1 and 2.

The hardness of rocks as it has been variously defined may be determined by different methods. The first method is one in which the proportionate average of the hardness of minerals making up a rock is the basis for classification. The other factors of grain size, shape, arrangement, and binding power are not considered.

There exists, as may be seen from the foregoing table, a very definite relation between the hardness as here determined and the percentage of silica in a rock.

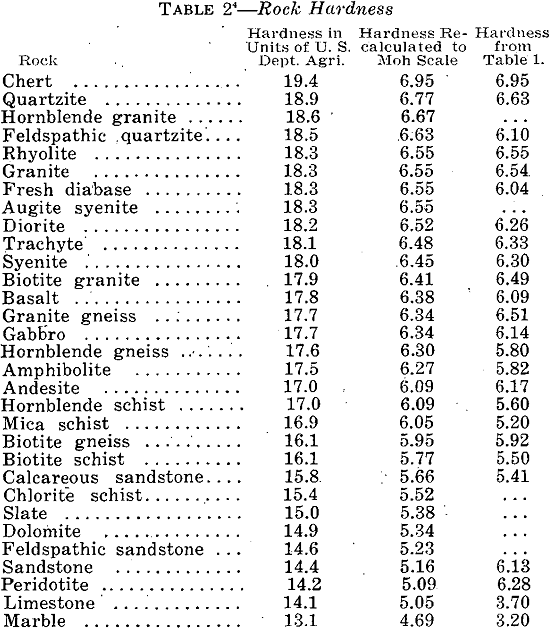

The second method, developed by the Office of Public Roads and Rural Engineering, U. S. Department of Agriculture, uses as the measure of rock hardness the loss of weight of uniformly-shaped rock specimens held against a revolving disc, with quartz grains as an abrasive. The units used in these tests are expressed in the first column of Table 2. The values are obtained by arbitrarily selecting 20 as the hardness figure for comparison with other tests and deducting from this one-third of the loss of weight of the specimen per 1000 revolutions of the disc.

By using the value of rhyolite in these units, and also its corresponding value, 6.55 from Table 1, the second column in Table 2 was calculated. In these tests, however, abrasion is the critical factor measuring hardness, while impact is negligible. As impact is an important factor in drilling, this method measures rock hardness only in part. However, other writers have used these data as the best available from which to compile rock tables. Since these were prepared, many more rock determinations have been made which are the basis for Table 2.

Harley has devised a third very useful method for classification. Determinations of hardness for underground work are obtained by the drill-test method, but instead of expressing the hardness as the function of the drilling speed, the energy required to cut a unit volume from a drill hole is used. The latter method eliminates those variables which exist in the former, such as type of drill, air pressure, and bit size. The units used by Harley are alphabetic and convey little meaning without careful study. The hardest rocks, or those requiring the largest energy input to drill a unit volume of drill-hole, are classed as A+, A, and A—, using three groups for each letter.

The softest rocks or those requiring the least energy input per unit volume drilled are classed D+, D, and D—, with the rocks of intermediate hardness between. The application of this nomenclature to the different rocks such as granites, syenites, diabases, etc., is not given. By this method, whether the drill-speed or energy-volume measurements are used, the comparative results will be influenced by the age and condition of the machine, the kind of drill steel, method of tempering, and shape of bit. By using a stoper drill as recommended by Harley, operated vertically, the personal equation in drilling is largely eliminated.

These results represent values of hardness made on hundreds of specimens and are average figures for rocks classed under any given name. With the exception of a few discrepancies, the hardness values from Table 1 check in a general way the values obtained by the totally different method represented in Table 2.

Tables 1 and 2 are interesting, but a more valuable classification could be obtained by comparing both drilling speeds and energy determinations per unit volume of drill-hole cut. These data could be obtained from mine operators on rocks of different types and classes. In order that testing conditions be as uniform as possible, the following are suggested:

The machine drill should be of standard make, preferably Ingersoll-Rand, as these rock drills are widely distributed and have been carefully tested on Quincy granite. A stoper drill, operated vertically, is preferable, for this eliminates variations due to the drill runner, and also reduces friction of the drill bit on the side of the hole. Air pressure should be constant at 80 or 90 lb. per sq. in.

The bit should be a double-taper cross-bit, with a 90 deg. cutting edge. The bits should preferably be 1 7/8, 1¾ and 1 5/8-in. diameter. The hole should be collared to a depth of about 2 in., then a new steel used and run for about 1 min. The depth of hole and its average diameter should be obtained so that both the drilling speed and energy per unit volume cut can be calculated. From five to ten tests on each different type of rock would give useful results. As complete a description as possible of the rock should likewise be given so that it may be properly classified.

In this test there are still a number of variables. By using as new a machine as possible, however, or one recently overhauled, the difference of energy developed by new and old machines will be considerably decreased. Steel tempered by standard methods should largely eliminate the variable hardness of the drill-bit.

A table of the relative toughness of rocks should indicate the relative amount and strength of explosive required for its most economical breaking. Toughness in a homogeneous rock is largely determined by the shape and arrangement of the component grains and by the strength of the binding minerals.

The difficulty in compiling such a table is that rocks are not homogeneous, uniform massive, and unaltered. Moreover, in any series of practical tests in any given rock to obtain toughness directly by a powder consumption method, the character and proximity of fractures, bedding planes, slips and shear planes, as well as the degree of alteration will introduce further variables.

In addition to toughness, in any given rock, the following factors will influence the powder consumption per unit of rock broken: (a) the strength and character of the explosive; (b) depth, size, number, and orientation of holes; (c) desired size of the blasted product, and (d) number of free faces of rock blasted.

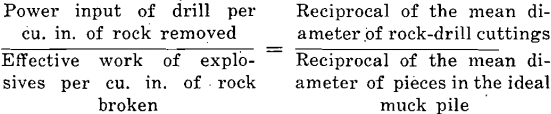

Harley takes into account some of these factors in arriving at approximate determinations of the explosive energy required in blasting. He develops a relation between the power input of a rock drill in cutting a hole and the effective powder energy required to break a rock. The work done in both of these cases is measured by the reciprocal of the mean diameter, of the comminuted rock. His equation follows:

This relation is corrected by two factors, one that is a function of the number of and distance between slips, shear planes, and lines of weakness, and the other a toughness factor that is a function of structure, texture, and chemical composition.

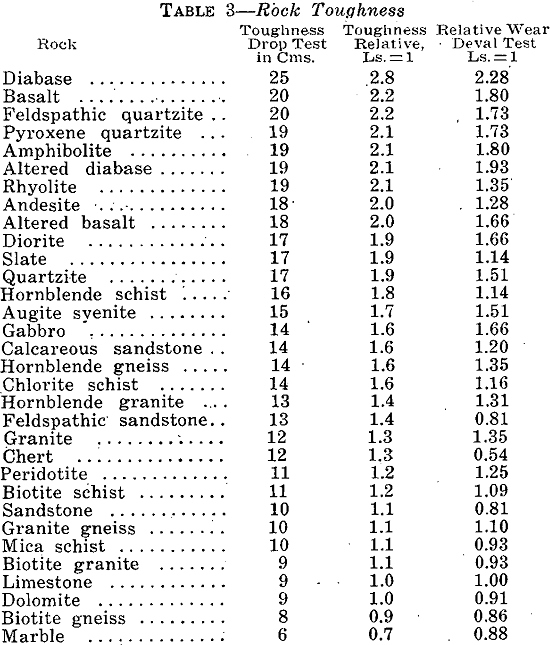

However, no such data as the foregoing are obtainable at present for compiling a rock table, but a very extensive series of toughness tests have been made by the U. S. Department of Agriculture. In these determinations, a Page impact machine causes a falling weight to repeatedly strike the specimen with greater and greater force and eventually to crush it. The height in centimeters of the blow at failure is recorded as the toughness of the material. These values are given in the first column of Table 3.

In the second column are the relative values, using limestone as one. The third column represents the relative values of wear produced on rock particles, treated in the Deval abrasion machine, which is a cylindrical mill, whose axis is at an angle to the axis of rotation. The feed is sized and no rock or metal balls added. Wear in this mill is produced by impact and abrasion, so that the results should, to some extent, measure the hardness of the rock, but to a larger extent its toughness. These wear values check in a general way the toughness values.

The foregoing compilations of tables of rock hardness and toughness have been obtained by using the Moh scratch test determinations of mineral hardness and the data of the U. S. Department of Agriculture. Alphabetical values for the hardness classification of rocks have been replaced by quantitative values, as those, possess a clearer and more definite meaning to the engineer. To supplement these hardness values, a standardized method of determining drilling speeds and energy consumption per unit volume drilled has been suggested. With the data from these tests available, a table can be compiled from which the drilling speed in any given rock, under standard conditions, may be closely estimated.

The table for relative toughness should likewise be supplemented by information regarding character and quantity of explosive required for breaking the most economical rounds in all kinds of rock. If determinations along the lines proposed by Harley were carried out in a large number of rocks, very useful information would certainly be available.

Discussion

G. A. Packard, Boston, Mass.—The value of knowing the relative hardness of rock has been recognized and several machine drill companies have tried to devise some way by which they could determine how many inches per minute any specific drill could be expected to drill in the rock in a particular district. One of the first methods was by testing the rock with the Brinell test, which is done by exerting a certain definite pressure on a small steel ball placed on the rock and then measuring the amount of indentation. That was found to be unsatisfactory because the rock often split before they would get any indentation.

Then they tried the scleroscope, which is based on the rebound of a falling ball on the rock to be tested. That was found to be somewhat more satisfactory. I have been told that one of; the companies went so far as to obtain specimens of rock from different mines in the same district and from different mines in different districts and made scleroscope tests on these samples. I think they made two tests on every sample, one with the grain of the rock and one across the grain, and they found quite a considerable variation.

I think the variations were as much as the difference between 60 and 90. They decided that it was impossible, by those methods, to obtain any satisfactory results. Nevertheless, it is certainly an important subject in comparing work in drilling and blasting.

G. S. Rice, Washington, D. C.—The Bureau of Mines has not made much progress in this problem of standardizing the strength of rocks. We had begun the study of their relative resistance to unit-strength blasting. We thought that we might be able to get up a comparative scale by attempting to measure craters. This was done by selecting, in different mines, places where the rock was fairly homogeneous, putting in a hole of fixed depth and blasting it with a definite quantity of dynamite of a certain strength, then determining the amount of material which was blown out. A good deal of difficulty was experienced and that series was suspended for various reasons.

I am not sure it is the right method, but it is worthy of consideration by this committee; and I would like to see a special committee appointed to consider methods of standardizing in the two lines, drilling and blasting. Our preliminary studies indicated that the work of the Bureau of Roads could not be used except with caution because its purpose is so entirely different from the problems in mining. It is probably unwise to try to consider hardness and toughness in one scale because, for example, limestone appears near the bottom in all three tables, yet limestone under some conditions is pretty hard to break.

B. F. Tillson, Franklin, N. J.—I endorse the suggestion that the Institute and other agencies combine in making as thorough a study as possible of the two problems presented in this paper.

It seems surprising that mining engineers’ have gone along so many years without attempting, so far as I know, to make a more thorough study of the fundamentals of the business, and certainly the first thing in mining is to learn the mechanics of penetrating the rock so that you can place the explosive, and the next is the properties required to disrupt that rock.

I regret that I cannot endorse the suggestion of scales of hardness and toughness as a criterion in the matter. As far as the hardness of rock in drilling is concerned I think such a scale would only increase the confusion by associating the idea of the distinctive hardness with what I should like to term as drillability. Why not call it the drillability of rock that we are dealing with arid make a scale of that sort? Why not avoid the possibility of confusion in our minds of a numerical system and go to the alphabetical system which somebody else has suggested or any other system of nomenclature which may be desired?

Mr. Rice has referred to the question of limestone. If a standard rock-drill test be run for 3 min. in a Barre granite, before the first minute has passed the bit is dull, there is no sharp cutting edge. So the average for the 3-min. run in drilling speed per minute will fall below the work of the same machine in limestone, because at the end of the first minute or even the third minute in limestone the bit is not dull.

The limestone rock is not siliceous and has no abrasive qualities to spoil the cutting edge of the bit, but if you should consider only the first minute in the Barre granite you would find that the penetration rate per minute was higher than it was in limestone.

Another substance which is hard to drill is hornblende-gneiss. It acts as a cushion in absorbing the shock of the cutting edge of the bit, and evidently being resilient enough to absorb some of those blows without reaching its own elastic limit, the progress in cutting it is slow. In a harder rock, so far as the hardness scale in testing is concerned, you may find that its brittle nature will permit rapid progress so long as there is a cutting edge on the bit. As a matter of fact, a drill steel which has no cutting edge at all may be used and you will make some progress in boring a hole without a cutting edge on the bit.

The theoretical concept was that if a cutting edge sharper than is used in practice were employed it would be better. Such a cutting edge cannot be maintained long enough as a matter of practical use. I have experimented with synchronizing the blows in the rotation of drill steel to try to chip the rock off in a series of steps. I do not believe we have secured that condition in practice.

What we have is an irregular, fairly plain surface on which we are impressing the cutting edge of the bit. What happens when a projectile strikes an armor plate without piercing it? At the point at which the projectile meets the armor plate a crater is produced and the material is raised on that side. On the other side of the armor plate a spall of metal is projected through the air at considerable velocity.

This projectile acts with a compressive force in the armor plate. All compressive forces, when they come to a free face in which the bounding material has a lesser density than the material in which the force is invoking stresses, are resolved into tensile stresses. The force of compression within the armor plate when it comes to the- free face becomes a tensile stress; the tensile stress causes a fragment of material to be thrown away.

When the drill-steel cutting edge strikes the rock, various factors come into play. There is a penetrating effect, that is resisted by both the shearing strains and the crushing strains of the rock immediately beneath the cutting edge. With a sharp-edged bit, that stress is resolved outward in the compressive forces at a slight angle to the free face and causes spalls from the resultant tensile forces to fly off. In a softer rock, one more easily penetrated, it penetrates farther, therefore a greater amount of force is developed at a slight angle to the free face and, therefore, the spall from the greater depth is larger.

The factors involved bear on not only the hardness of the rock, or the minerals that constitute it, but they also depend on the modulus of elasticity of the material, its tensile, shearing, and crushing strength. It seems to me that the strength of the combination cannot be worked out by an analysis of the different minerals, because it depends largely on the bonding of those minerals. Where there are a number of minerals bonded, their tendency to fly off in spalls is affected by that condition of bonding. A very brittle material, although it may be very hard, if it has a high elastic efficiency, is more likely to spall than a material which has a low elastic efficiency and absorbs within itself a larger percentage of energy probably transformed into heat instead of being effective as a disruptive force.

The rubber people make tests as to the abrasive quality of rubber, which is not the same thing as the tensile strength of the rubber; its penetrability is another and its resiliency is still another. The abrasive quality cannot be measured by the penetrability or the tensile strength of the rubber; it is a different function and has to be measured by methods similar to those used by the Department of Agriculture in determining the abrasive qualities of rocks, but I do not think that enters into it at all, so far as we are concerned. An abrasive test is highly valuable because abrasion is a quality required in rocks for road purposes but it is not in drilling.

So far as explosives are concerned, I surely hope that we can arrive at a method for determining the effective blasting force of an explosive. Of course there are conditions where the propulsive force in an explosion may be desirable in order to move the rock farther away from the face. We can find other mechanical methods of moving that rock cheaper than by explosives. What we desire, I think, is to find out how we can measure the effective force, that force which will stress the rock beyond its elastic limit, thereby fracturing it but letting it remain in its original position.

A. Notman, New York, N. Y.—I happened to be concerned in some of the first experiments along this line which were later followed up by Mr. Harley’s work, to which reference has been made in this paper. You may be interested in the reason for initiating it. At the Copper Queen mine we had been experimenting with day’s-pay work and contracts and had finally become discouraged with the problem of contracting, because we had an extraordinarily wide range of conditions to meet in breaking ground.

We had ground in which the best rock drills then available (along in 1911 to 1916) would not drill more than 1½ in. per min. and then we. had ground that you could stick your finger in, with all the possible variations in between. In setting contracts for definite periods of time, it became pretty much a gamble as to whether the foreman who set the contract or the miner who took it got the best of the bargain. As you can readily imagine; the company always got the worst of it, because if the fellow did not make any money on his contract, then it would have to be made up to him the next time.

We tried to develop some method better than day’s pay that would insure the company paying only for the work that was done; paying liberally for that but not paying for anything that was not done. We endeavored to standardize conditions under which development work was carried on, and to do that we went over thousands of feet of drifts that had previously been driven and on which we had performance records. At the same time we began collecting the data on the current work that was being carried on.

The factor used was the footage per man-shift. After examining the work of several years this way, we finally felt that we were sufficiently well informed to try a few untimbered drifts, on a bonus basis, based on a man having to do a certain standard performance in each character of ground that he encountered. That is to say, he was paid at the end of the period according to his performance in the ground that he actually worked. We were not guessing as to what he was going to encounter, but we paid him only on the work in the ground that he actually went through.

The classification of the ground has already been pointed out. It involved a great many factors. First of all, and to my mind still the most important factor, is the drilling speed that you can expect to get in that ground, because that determines how much hole you can make in it. After that you have got to know how many holes it is going to take to break the ground and then you become involved in all these myriad factors that enter into the question as to how readily the ground will break.

My conclusion is that while it may take a long time, (perhaps we may never reach the goal of being able to standardize ground for all the mines in all the districts) I do feel that any individual property, after a few years’ study and experience, can standardize its own conditions and determine what are the best methods to pursue in that particular ground. Of course, comparative study of results in different properties will help but, after all, the question begins right at home in starting to determine the factors for your conditions.

If you can see your way clear to use nomenclature or other factors that are interchangeable between properties, all well and good. I think that the real benefit of discussion will arise from people being interested in standardizing at home. I might say that the result of the campaign which was conducted at that time had a very important economic bearing. The performances were increased some 60 per cent on development work. I do not mean to say that the study itself effected that result, but a number of other factors were varied advantageously as a result of an intensive study of this particular phase. The probabilities are that a great many places will reap perhaps somewhat similar benefits from such an investigation.

Written Discussion

E. D. Gardner, Tucson, Ariz.—In discussing a problem that has as many angles and phases as the drilling and blasting of rock, it appears essential, as has been pointed out by Dean Probert, to define the terms used in order to prevent confusion. Gyss and Davis have used the term “hardness” of rock to define its resistance to drilling, and “toughness” to define its resistance to withstand rupture. It appears that these terms in this connection are used rather loosely, and I prefer the recently proposed words “drillability” and “blast- ability” as being more definite.

The U. S. Bureaus of Mines has been conducting an investigation of blasting problems in metal mines for four years, and a number of papers by myself and others have been published on different phases of the subject. The value of determining the qualities or characteristics of the rock affecting drilling and blasting was early recognized in this investigation and an effort has been made to work out a practical classification. A limited amount of progress has been made.

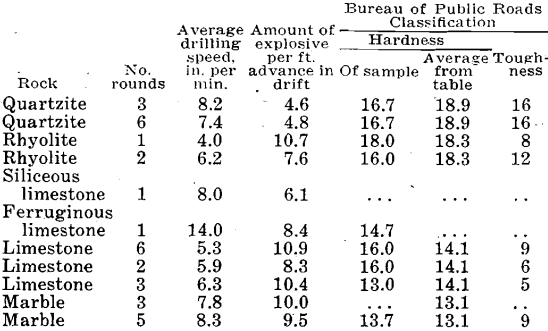

Rock samples from the places where blasting tests have been made have been tested by the Bureau of Public Roads. In addition to testing for hardness and toughness, the rocks have been tested for percentage of wear, weight per cu. ft., percentage of absorption, crushing strength, and shearing strength. The hardness and toughness of the rock undoubtedly have a relation to the speed of drilling. However, it has been found that these characteristics as determined by the Bureau of Public Roads methods have no constant relation to actual drilling speed. It is also probable that other qualities of the rock, such as compactness, influence the rate at which a rock can be drilled.

The classification of hardness and toughness used by the Bureau of Public Roads was designed to test material for road-building purposes and not for drilling speeds. As far as I know, the only reliable method of determining drilling speeds is by actual drill tests. However, one who is familiar with the ground and with drilling operations can quite frequently closely estimate the speed at which a face can be drilled by observation and by testing the rock with a pick point. It is quite possible that an accurate method of testing rock for drillability can be devised. A simple method of making such tests of rock would be of great value to the mining industry.

As pointed out by others, limestone is placed at the bottom of the scale in the tables by Gyss and Davis. Some of the most difficult rock to drill and break that I have had experience with has been limestone. Quartzite is near the head of the list, yet quartzite in some places is fast-drilling and easy to break.

Mr. Harley has worked out an interesting method of making drilling speed tests. It is necessary to know the drilling speed to properly classify ground for contract or bonus purposes. Also, this knowledge is useful in planning the proper sequence of operations in a mine. As the time of changing steel and adjusting the drill is about constant in most cases, the actual drilling .time is that desired. However, fractures or clayey seams in some ground cause the drill steel to stick in the holes, and when this is the case proper allowance must be made when classifying the rock.

Although the speed at which a face can be drilled under the conditions existing in the working place is the one used by the mine executive, a comparison with a standard test would be of value in checking the efficiency of his drilling operations. The following table gives the results of blasting thirty-five test rounds at eleven different places in the Copper Queen Mine, Bisbee, Ariz. A rock sample was taken from each place and tested by the Bureau of Public Roads. The results of hardness and toughness are given in the table, along with the average hardness for each rock, taken from the paper by Gyss and Davis.

From the table it can be noted that the hardness index as determined by the Bureau of Public Roads methods has no general relation to the drilling speed.

Rock in metal mines almost invariably contains planes of weakness and jointing planes. The plane of weakness in the rock is the greatest single factor governing the amount of explosive required to break a given round. This has been demonstrated by observing the results of blasting over 150 test rounds in various mines. The effect of planes of weakness is so important that, generally, any variation of resistance offered to the explosive due to differences of toughness of the rock, as defined in the paper under discussion, would be masked.

It will be noted from the table that the index for toughness cannot be applied to the quantity of explosive required to break a round in the series of tests shown. However, other tests indicate that the hardness and toughness of the rock as determined by the Bureau of Public Roads methods appear to influence the size of the broken material brought down by blasting.

Although there is a general relation between drilling speed and amount of explosives required to break a drift round, this relation is not by any means constant and can be used only in some cases for estimating the quantity of explosive required to break a round. The qualities of the rock that cause the ground to resist fracturing, or the formation of planes of weakness, by external forces probably indirectly influence the amount of explosive required to break a round. These same qualities that affect the planes of weakness also probably influence the speed of drilling, and when this is the case there is a direct relation between drilling speed and the amount of explosive required to break the ground.