Batch Laboratory Flotation Testing starts from the 3 fundamental types of flotation processes or methods which can be classed as either:

- Bulk flotation

- Differential flotation

- Sequential flotation

While all flotation processes are selective or differential in that one mineral or group of minerals is floated away from accompanying gangue, bulk flotation generally refers to separation of unlike mineral types such as sulfides from non-sulfides. Differential flotation (exemplified, for instance, by the concentration and subsequent successive removal of Cu, Pb, Zn and Fe sulfides from a single ore) on the other hand, is restricted to operations

involving separation of similar mineral types.

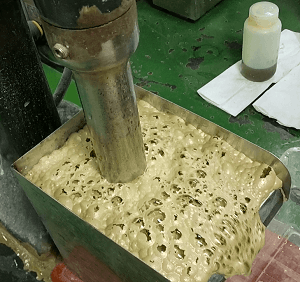

Batch Froth flotation Testing is a means of treating a pulp of finely ground ore so that it yields the valuable or desired mineral in a concentrate that will be amenable to further processing. The process involves the imparting of a water repellent (hydrophobic) character to the wanted mineral particles by chemicals that are called collectors or promoters. Under favorable conditions, these chemically coated particles become attached to the air that is bubbled through the pulp, and will thus “float” on the surface.

If the surface tension of the pulp is then reduced by a second chemical, called a frother, a stabilized froth containing the wanted mineral particles will form on the surface of the pulp. This froth can then be skimmed off to yield a concentrate in which the desired mineral is present in a much higher percentage than in the original ore.

When conducting a flotation experiment the following procedures should be completed before starting the tests.

Planning the lab flotation test:

The test objectives and therefore information required from the results should be established (e.g. sizings, assays, rates of flotation and treatment of products, etc). Knowing the information that is required, the test can be planned with regard to the following:

- Cell type and size to be used

- Feed sample weight required for each test

- Water quality and quantity to be used

- Floatation density, etc.

Flotation Reagents

All reagents to be used during the test should be prepared at the required strengths prior to commencement. The freshness of some reagents is important. Remember the more dilute the reagent, the more accurate is the addition rate but the higher the volume addition to the cell.

Flotation Equipment Preparation

All equipment should be thoroughly cleaned prior to the test (and after completion of the test), and all product trays and reagent dispensers properly labelled.

Sample Origin

It is sometimes helpful to gain information from previous tests of a similar type or performed on the same feed source, to become aware of any problems which may occur during the test (e.g. amount and nature of sulphides, feed size distribution, frothing problems, etc.)

Lab Equipment and Procedures.

Batch Laboratory Test Plant

Every mine large enough to justify the installation of a concentrating mill should be able to increase its profits by installing a conveniently arranged ore dressing laboratory. The laboratory may consist of a few essential items or of a very complete installation, depending upon the size of the mine and the complexity of the ore dressing problems encountered.

The Batch Laboratory Test Plant makes it possible to conduct tests for flotation, gravity concentration, amalgamation, cyanidation, or any combination of these processes. Batch laboratory machines can be supplied to suit the customer’s individual requirements as necessity at various times dictates. Mining companies frequently install a nucleus of equipment to which various additions are made as the value of testwork becomes increasingly apparent.

Many mining schools throughout the world have practically standardized on Batch Laboratory Equipment and have made complete installations of Batch Laboratory Test Plants. This wide acceptance is due not only to dependable metallurgical results, but also to the fact that Laboratory Machines demonstrate the principles of standard commercial machines. Government and private testing laboratories use Laboratory Machines because they require units from which standard, accurate results can be obtained and results which can be duplicated in commercial practice.

Continuous Laboratory Test Plant

The installation and operation of a commercial plant may involve problems which should be studied under small scale continuous operating conditions. The results secured from such study will eliminate the need for costly experimentation with large tonnages of ore when the commercial plant is placed in operation, and assures selection of the proper size and type of equipment. The Continuous Laboratory Test Plant offers ample opportunity for the study of many complex problems and thousands of tests have been conducted on widely varying types of materials and ores from customers throughout the world. Following are examples:

- The milling of ores by fine grinding and flotation requiring the establishment of closed circuits where middling or unfinished products are returned to various points in the flowsheet for additional treatment.

- The treatment of complex ores by new processes or by the use of new or unusual reagents in flotation.

- The milling of complex ores requiring the use of combined methods of treatment such as gravity concentration and flotation, or coarse flotation followed by slime flotation, or gravity and amalgamation followed by cyanidation.

- The cyanidation process for the treatment of gold and silver ores involving the continuous re-use of much of the cyanide solution after removal of the dissolved gold or silver by precipitation.

- The treatment of tonnage lots of ores and industrial materials by continuous pilot plant operation as a separate circuit or as part of a circuit in a commercial plant.

Recent advances in the art of flotation have broadened the scope of flotation testwork to include materials not previously considered. Besides the metallic minerals, industrial materials and products are now being successfully treated. Coal, cryolite, bauxite, phosphates, apatite, feldspars, syenite, ilmenite, and salt are being concentrated; also milkweed, resins, and grain.

Continuous Laboratory Test Plants are used extensively by universities and government bureaus for research in ore dressing, and by mining companies to determine method of treatment and layout for new projects. With the development of the No. 8 “Sub-A” Laboratory Flotation Machine, continuous testing in parallel with standard mill circuits has become mechanically practical. This allows changes in grinding, conditioning, emulsifying, and reagents to be made under identical mill feeding and mill operating conditions without interruptions or fluctuations in the main circuit.

Using as a basis the three sizes of “Sub-A” Laboratory Flotation Machines available, namely the Nos. 5, 7 and 8, these plants can be furnished to fit each particular requirement. The No. 5 has a capacity of 50 to 150 pounds an hour, the No. 7 of 200 to 500 pounds an hour, while the No. 8 will handle 1,500 to 2,500 pounds an hour. These capacities depend, of course, on the material being treated.