Table of Contents

- PAN, Gold Washing, Miner’s—Made of polished copper. Diameter 16 inches.

- PAN, Gold Washing, Miner’s—Made of polished steel. With rolled edges.

- PAN, Gold Washing, Miner’s—Similar but with copper bottom, for amalgamating. Diameter, 16 inches.

- PAN, Gold Washing, Miner’s—Similar but with silver plated copper bottom. Diameter 16 inches.

- PAN, Vanning Plaque, Richard—Made of iron, white enameled. Diameter, 10 inches.

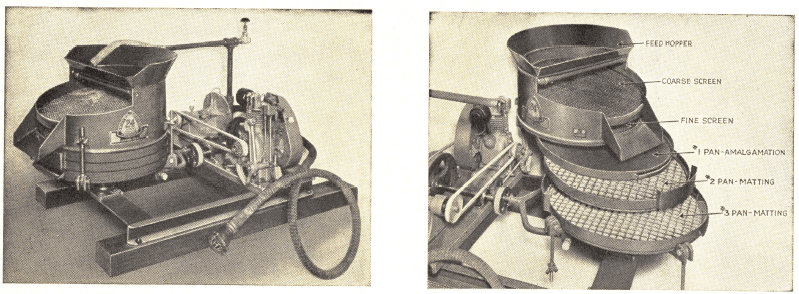

Denver Mechanical Gold Pans

PAN, Gold, Denver Mechanical (Placer Machine), No. 24—Utilizes the operating principle of the hand gold pan, but greatly increases the tonnage, making a practical, commercial gold saving unit. The motion is secured by tilting the nest of pans, and the shaking movement is obtained by a steel yoke and saddle which is connected to a rotating eccentric giving an oscillating motion. The drive is from a small ¾ H. P. gasoline engine which is also large enough to drive a small pump for furnishing the water necessary to operate the unit.

The gravel is fed into the hopper where it is thoroughly washed as it passes over a coarse screen, then over a finer screen, the final product falling on the first concentrating pan. There are three pans, all 24 inches in diameter. The first pan is usually of copper for coating with amalgam to recover the finer gold particles. The other two pans are of steel with rubber matting placed in the bottom and covered by wire which produces a swirling action to the mass with a natural aid in recovering the heavy gold or any floured mercury.

The unit will handle approximately as much as one man can shovel, and operating expense is low, as one gallon of gasoline will run the machine for about ten hours. The machine is made of metal and mounted on structural steel making it rugged for moving from one gold deposit to another. It is built for service, does not require a stock of repair parts and will give satisfactory recoveries on gold placer sands.

With steel frame, 3 pans, hopper and screens, with ¾ H. P. gasoline engine, flywheel and “V” rope drive, ¾ inch pump and 10 feet of suction hose with foot valve. Capacity, 1½ to 2 tons per hour of bank feed. Dimensions, 4’10″x2’10″x2’6″. Shipping weight, approximately 700 pounds.

PAN, Gold, Denver Mechanical (Placer Machine), No. 36—Similar to but larger, with 4 pans instead of 3 pans, and equipped with 1½ H.P. gasoline engine and 1 inch pump, giving a capacity of 4 to 5 tons per hour of bank feed. Shipping weight, approximately 1000 pounds.

TROMMEL SCREEN, 18 inch—While for most applications the standard Gold Pans are sufficient, in some instances the material to be handled contains considerable clay and for such work the Trommel Screen is suggested. The Trommel Screen gives thorough disintegration and breaking up of concentrate particles.

The equipment supplied consists of washing and screening sections with steel supports and steel mechanism, arranged to mount on a standard Denver Mechanical Gold Pan, either the No. 24 or the No. 36. Shipping weight, approximately 450 pounds.

We can also supply both the No. 24 and the No. 36 Denver Mechanical Gold Pan in Twin Units, with double the capacity of the standard pans. Further details on the standard pans and on the Twin Units will be supplied on request.

CONCENTRATING TABLE, Denver, Type 4—Suitable for use with Denver Mechanical Gold Pans.

- PAN, Sampling—Enameled steel for ore samples.

- PAN, Sampling—Made of seamless tin, for ore samples.

- PAPER, Cross Section, English—Ruled in 1/10 inch divisions, with heavy inch lines. Size of sheet, 8½x11 inches ; ruled area, 7×10 inches.

- PAPER, Cross Section, Metric—Printed from an engraved plate, one millimeter divisions with heavy centimeter lines. Size of sheet, 22×28 cm. ; ruled area, 18×25 cm.

- PAPER, Glazed, Black—For mixing pulverized ore, etc. In sheets 10×12 inches.

- PAPER, Glazed, White—For mixing pulverized ore, etc. In sheets 10×12 inches.