Table of Contents

3″ x 6″ Jaw Crusher

AKA

75*150 Rock Crusher

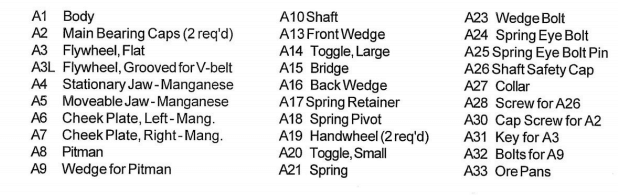

The extra heavy frame is cast in one piece and reinforced for greater strength where necessary. The shaft is of a special nickel chrome alloy and is practically unbreakable under the most rigorous conditions. Pulleys and balance wheel are of extra heavy construction and provide ample momentum. Jaws and cheek plates are manganese steel casting and have a very long life. Jaws are reversible and all are very easily replaced. The vibrating jaw is mounted upon an eccentric at its upper end and rests against a toggle at its lower end. The eccentric imparts a circular or gyratory movement to the upper end while the toggle compels the lower end to describe a small arc. This motion is both forward and downward and helps the discharge.

Adjustment:

Adjustment is made by a hand screw behind the shaft. This lifts a solid wedge and forces the movable jaw forward. The entire adjustment is oversize so that there is practically no possibility of it becoming damaged. Two sizes of toggles are provided to compensate for the wearing of the jaw plates. If by accident a bolt or nut, or other uncrushable material, should get between the jaws, the toggle is designed so that it would be the first part to break and it is easily and cheaply replaced.

Specifications:

Capacity, depending on type of ore, 600 pounds per hour; jaw opening, 5-3/4 x 2-3/4 inches; pulleys 13 x 2-1/2 inches; RPM 350-450; power required, 2 HP, weight 340 pounds (bare).

750 pounds, on base c/w drive

Minimum Setting ………………………………….. 1/16″

Maximum Setting……………………………………. 3/4″

Maximum Feed Size………………………………….. 2″