Table of Contents

RP-4 Shaker Table Instructions Manual

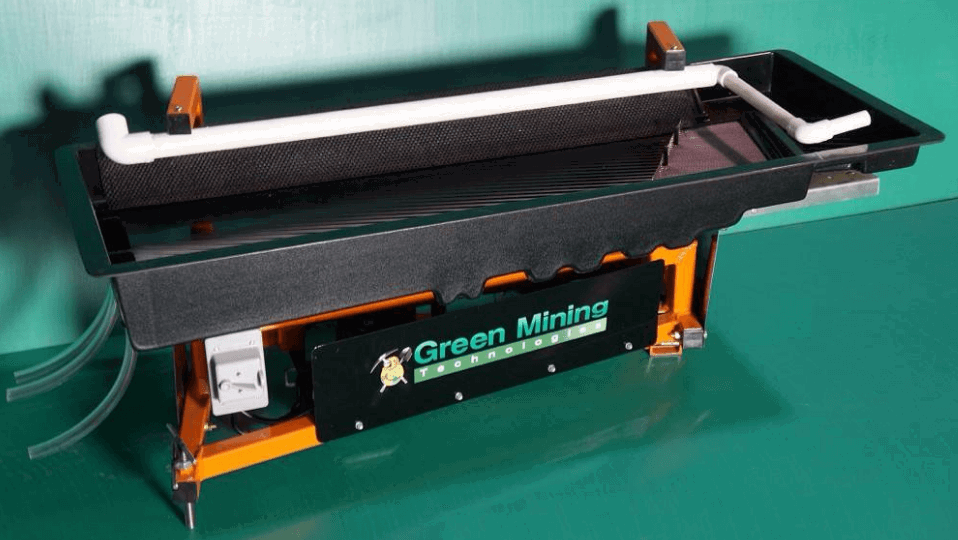

RP-4 GOLD SHAKER TABLE

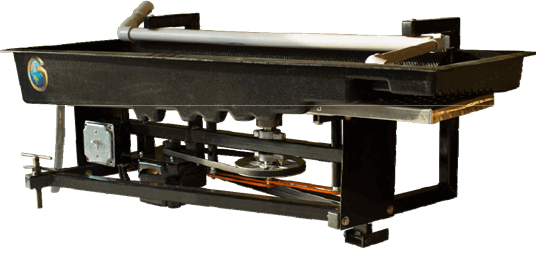

All RP4 shaker tables operate best when firmly secured to a dense solid mounting base. Wooden stands will set up harmonics and vibrations. Dense concrete or solid bedrock is preferred or a heavy braced steel table sitting on concrete. Mount shaker table to solid bed rock if possible when operating in the field. When that is not an option, six or seven sand bags may also be used if concrete or bedrock is not available for mounting.

Vibration and/or harmonics will have a negative effect on the concentrating action of the deck and a negative scattering effect on the gold.

LEVELING THE RP-4 SHAKER TABLE

DO NOT LEVEL ACROSS OR ON TOP OF THE TABLE’S DECK RIFFLES.

Place a level on top of the steel bar that extends between the two bolts down mounting feet. Use flat washers installed under either end of the mounting feet for precise level adjustment in the long axis.

Read Level across your Table’s Back Bar

Optional Gravity Shaker Table Stand

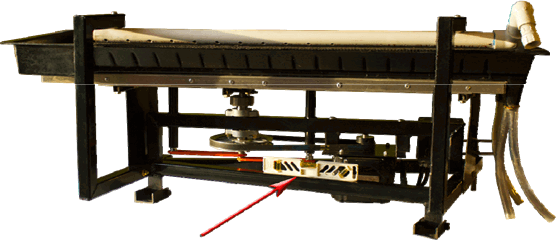

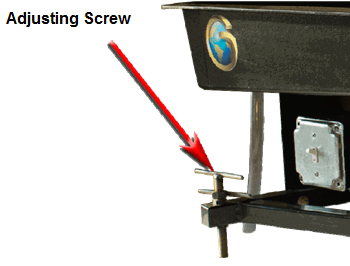

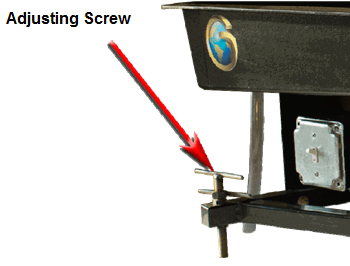

| Horizontal slope of table will change by adjusting the slope tilting screw up or down for precise control of concentrate line. Occasional apply lubricant to threads. |  |

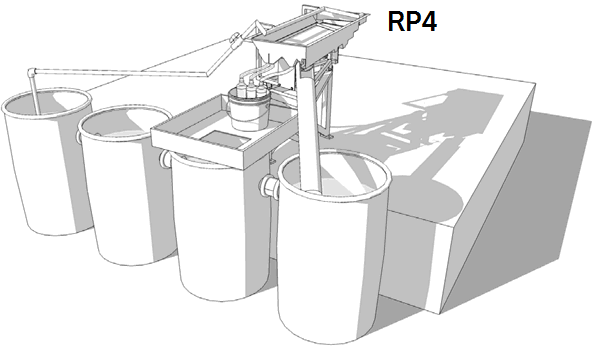

RP4 SETTLING OR CLARIFYING PONDS

At no time should sand or slime be re-circulated back with mill water. Large, calm, surface areas are required to settle slimes. Buckets, barrels or any deep containers with turbulent water will not allow slimes to settle. Tailings should discharge into a tails pond or into a primary holding vessel before entering slime settling ponds. Surface area is more important than depth. A small 10 x 20 ft. settling pond can be installed in about 30 minutes. Shovel a 6” high retainer wall of earth and remove all gravel. Lay a soft bed of sand in the bottom. A small raised wall area (with the top approximately 2” blow water level) should be placed around the pump area. Roll out plastic liner and fill with water. Desert areas require a plastic cover to retard evaporation. Use a 2×4 wood across pond and lay plastic.

SETTLING OR CLARIFYING CONTAINERS

As with ponds, at no time should sand or slime be re-circulated back with mill water. A calm surface is needed in the final two barrels to settle slimes. (In lieu of the last two barrels, the discharge from barrel two may be directed to a settling pond as outlined above.) Turbulent water will not allow slimes to settle. Tailings are discharged into the first container.

Note: Care must be taken not to overload the barrels if they are to be emptied without mechanical assistance.

COMPACT SHAKER TABLE TAILINGS THICKENER

A small compact tailings thickener introduces tailings feed at a controlled velocity in a horizontal feed design that eliminates the conventional free settling zone. The feed particles quickly contact previously formed agglomerates. This action promotes further agglomeration and compacting of the solids. Slowly rotating rakes aid in compacting the solids and moving them along to the discharge pipe, these solids are eventually discharged at the bottom of the unit. Under flow from the thickener 60-65% solids are processed through a vacuum filter and a 90-95% solids is sent to the tailings area. Tailings thickeners are compact and will replace ponds. A 23 ft. diameter will process flow rates at 800 gpm or 50 tph.

DEFLOCCULANTS AND WETTING AGENTS GOLD LOSSES

Pine oils and vegetation oils regularly coat the surface of placer gold. Sometimes up to 50% of the smaller gold will float to the surface and into the tails. The pine oil flotation method for floating gold is still in use today. A good wetting agent will aid in the settling and recovery of oil coated gold.

OPERATION OF THE RP-4 SHAKER TABLE

Magnetite Being Lifted Out of the Gold Concentrate

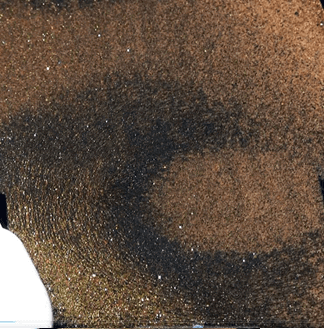

Separation of concentrate from tails Minerals or substances that differ in specific gravity of 2.5 or to an appreciable extent, can be separated on shaker tables with substantially complete recovery. A difference in the shape of particles will aid concentration in some instances and losses in others. Generally speaking, flat particles rise to the surface of the feed material while in the presence of rounded particles of the same specific gravity. Particles of the same specific gravity but varying in particle size, can be separated to a certain extent, varying in particle size, can be separated to a certain extent, removing the larger from the smaller, such as washing slime from granular products.

Mill practice has found it advantageous in having the concentrate particles smaller than the tailing product. Small heavy magnetite particles will crowd out larger particles of flat gold making a good concentrate almost impossible with standard gravity concentrating devices. The RP-4 table, using rare earth reverse polarity magnets, overcame this problem by lifting the magnetite out and above the concentrate material thus allowing the magnetite to be washed into the tails. This leaves the non-magnetics in place to separate

normally.

SIZING OF RP4 HEAD FEED MATERIAL

No established mathematical relationship exists for the determination of the smallest size of concentrate particle and the largest size of tailing particle that can be treated together. Other factors, such as character of feed material, shape of particles, difference in specific gravity, slope or grade of table dock and volume of cross flow wash water will alter the final concentrate.

Size of feed material will determine the table settings. Pulverized rod mill pulps for gravity recovery tables should not exceed 65-minus to 100-minus 95% except where specific gravity, size, and shape will allow good recovery. Recovery of precious metals can be made when processing slime size particles down to 500-minus, if the accompanying gangue is not so coarse as to require excessive wash water or excessive grade to remove the gangue, (pronounced gang), to the tails. Wetting agents must be used for settling small micron sized gold particles. Once settled, 400-minus to 500 minus gold particles are readily moved and saved by the RP-4 shaker table head motion.

Oversized feed material will require excess grade to remove the large sized gangue, thus forcing large pieces of gold further down slope and into the middling. Too much grade and the fine gold will lift off the deck and wash into the tailings. Close screening of the concentrate into several sizes requires less grade to remove the gangue and will produce a cleaner product. A more economical method is to screen the head ore to window screen size (16-minus) or smaller and re-run the middling and cons to recover the larger gold. This concept can be used on the RP-4 shaker tables and will recover all the gold with no extra screens. A general rule for good recovery is less grade for the table deck and as much was water as possible without scouring off the fine gold. Re-processing on two tables will yield a clean concentrate without excess screening. Oversized gold that will not pass through window screen size mounted on RP-4 shaker tables, will be saved in the nugget trap. Bending a small 1/4” screen lip at the discharge end of the screen will trap and save the large gold on the screen for hand removal.

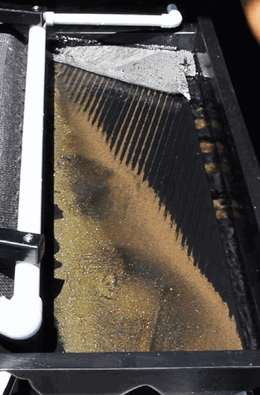

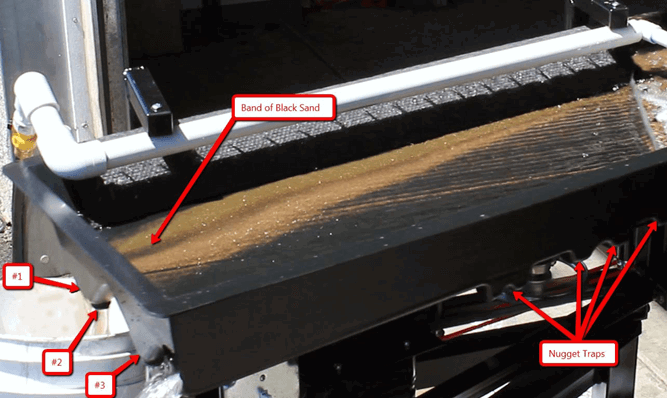

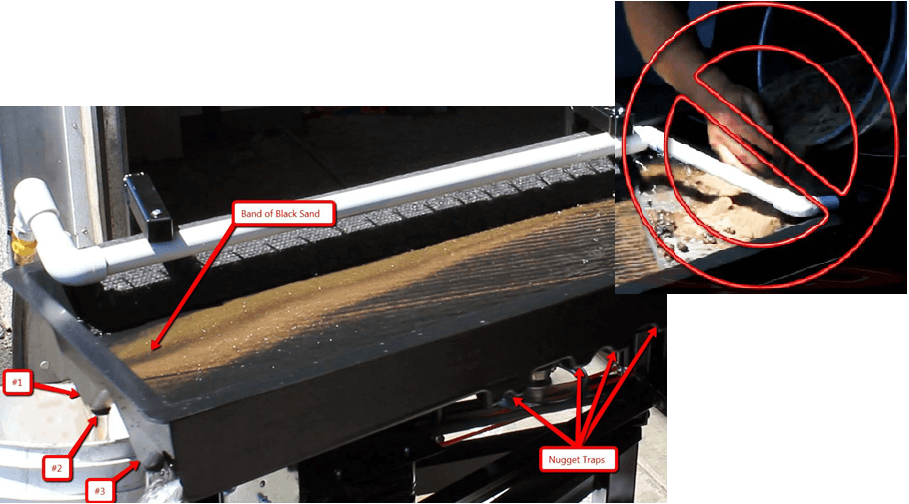

On the first run, at least one inch or more of the black concentrate line should be split out and saved into the #2 concentrate bin. This concentrate will be re-run and the clean gold saved into the #1 concentrate pocket. Argentite silver will be gray to dull black in color and many times this product would be lost in the middling if too close of a split is made.

SCREEN SIZING OR CLASSIFICATION OF SHAKING TABLE

The riffled portion of the RP-4 shaker table separates coarse non-sized feed material better than the un-riffled cleaning portion. Upon entering the non-riffled cleaning plane, small gangue material will crowd out and force the larger pieces of gold further down slope into the middling. Screen or to classify.

The largest feed particles should not exceed 1/16” in size. It is recommended that a 16-minus or smaller screen be used before concentrating on the RP-4 shaker table, eliminating the need for separate screening devices. Perfect screen sizing of feed material is un-economical, almost impossible, and is not recommended below 65-minus.

A classified feed is recommended for maximum recovery, (dredge concentrates, jig concentrates, etc.) The weight of mill opinion is overwhelmingly in favor of classified feed material for close work. Dredge concentrates are rough classified and limiting the upper size of table feed by means of a submerged deck screen or a mechanical classifier is all that is necessary. A separate screen for the sand underflow is used for improved recovery when using tables.

HEAD FEED MATERIAL & WASH WATER CAPACITY OF RP-4

Head feed capacity on the RP-4 tables will differ depending on the feed size, pulp mixture and other conditions. Generally speaking, more head feed material may be processed when feeding unclassified, larger screened sized material and correspondingly, less material may be processed when feeding smaller sized classified rod or ball mill pulps. Smaller classified feed material will yield a cleaner concentrate. Ultimately, the shape of the feed material particles and a quick trial test will determine the maximum upper size.

The width between the riffles of the RP-4 table is small and any particle over 1/8” may cause clogging of the bedding material. A few placer operators will pass 1/8” or larger feed material across the RP-4 table, without a screen, with the intent of making a rough concentrate for final clean up at a later date. This method will work, but excess horizontal slope/grade of the table deck must not be used as some losses of the precious metals will occur. Magnetite black sands feed material, passing a 16-minus screen (window screen size if 16-minus + or -) will separate without losses and make a good concentrate at approximately 500 to 600lbs feed per hour for the RP-4. Head feed material must flow onto the RP-4 screen, at a constant even feed rate. An excess of head feed material placed on the table and screen at a given time will cause some gold to discharge into the tailings nugget trap. Head feed material should be fed at the end of the water bar into the pre-treatment feed sluice. Do not allow dry head feed material to form thick solids. The wash water will not wash and dilate the head feed material properly, thus allowing fine gold to wash into the tails.

Feed material should disperse quickly and wash down slope at a steady rate, covering all the riffles at the head end, washing and spilling over into the tails trough. A mechanical or wet slurry pump feeder (75% water slurry) is recommended for providing a good steady flow of feed material. This will relieve the mill operator of a tedious chore of a constantly changing concentrate line when hand feeding.

Eight gallons of water per minute is considered minimum for black sands separation/concentration on the RP-4 shaker table. 15 gallons of water per minute is considered optimum and will change according to feed material size, feed volume and table grade. A 1” inch hose will pass up to 15 gpm, for good recovery, wash water must completely cover the feed material 1/4” or more on the screen.

PVC WATER DISTRIBUTOR

The PVC water distribution bar is pre-drilled with individual water volume outlets, supplying a precision water flow. Water volume adjustment can be accomplished by installing a 1” mechanical PVC ball valve for restricting the flow of water to the water distributing holes. Said valve may be attached between the garden hose attachment and water distributing bar.

More water at the head end and less water at the concentrate end is the general rule for precise water flow. More feed material will occupy the head end of the RP-4 shaker table deck in deep troughs and less material will occupy the concentrate end on the cleaning plane. A normal water flow will completely cover the feed material over the entire table and flow with no water turbulence.

A rubber wave cloth is installed to create a water interface and to smooth out all water turbulence. This cloth is installed with holes. Holes allow water to run underneath and over the top of the cloth and upon exiting will create a water interface smoothing out all the water turbulence. Bottom of water cloth must contact the deck.

Note: A shallow turbulent water flow without the wave cloth or no deflocculant / wetting agent and/or excess table grade will wash the gold further down slope and into the middling.

HORIZONTAL RP4 TABLE SLOPE

Avoid excessive slope and shallow turbulent water. For new installations, all horizontal grade/slope adjustments should be calculated measuring from the concentrate end of the steel frame to the mounting base. For fine gold, the deck should be adjusted almost flat.

PULP FEEDS

All head feed must be fed as a 75% water pulp. Clean classified sand size magnetite will feed without too much problem when fed dry. Ground rod or ball mill feed material 65-minus or smaller must be fed wet, (75% water slurry by weight or more) and evenly at a constant rate, spilling over into the tails drain trough at the head end of the table. Feed material without sufficient water will not dilute quickly and will carry concentrate too far down slope or into the tails. A good wet pulp with a deflocculant and a wetting agent will aid the precious metals to sink and trap within the first riffles, thus moving onto the cleaning plane for film sizing. Round particles of gold will sink instantly and trap within the first riffles. The smaller flat gold particles will be carried further down slope to be trapped in the mid riffles. Potential losses of gold can occur if the table deck is overloaded by force feeding at a faster rate than the smaller flat gold can settle out. Under-feeding will result in the magnetite’s inability to wash out of the riffles, thus leaving a small amount of magnetite concentrated with the gold. A small addition of clean quartz sand added to a black sand concentrate will force the magnetite to the surface and will aid in its removal. Slimes require a separate table operation.

CONTROL OF GOLD CONCENTRATE LINE

At some point on the concentrate end of the RP-4 table, separation of middling and concentrate must occur. Small changes in the volume of feed material, wash water, deck slope and other factors will affect and change the concentrate line formed on the cleaning plane, thus requiring attention. A belt feeder for dry or a slurry pump feeder for wet is recommended for large tonnages or commercial operations. Hand feeding is tedious and one cannot feed at a continuous rate, which will cause the concentrate line to change continually. Deck horizontal slope/grade is used for the final control of the concentrate line and for accurate splitting of the concentrate. A slope T handle adjusting screw on the RP-4 shaker table is located at the concentrate end of the table. The entire table assembly rotates, thus eliminating complicated splitting devices.

Middling will always contain some values and should be re-run if operating at a high volume or the concentrate line was split too close. Save at least 1” of the top concentrate line into the #2 nugget trap on the first run.

RP-4 NUGGET TRAP

A live bed nugget trap is molded into the tailings drain trough and will save all oversized gold that will not pass the submerged deck screen. The nugget trap should be cleaned periodically. When cleaning the nugget trap, the wash water and table deck should continue to operate with the head feed material shut off. This will allow the nugget trap to clean itself of all tails gangue. After the remaining tails material has moved off and out of the nugget trap, stop the water and reciprocating action of the table. The remaining heavy material should be hand washed out of the nugget trap, into a gold pan, and inspected for values.

NOTE: Excessive slope, overloading of feed material or no wetting agent during operations, will result in fine gold trapped in the nugget trap.

Continued operation of the table with water, during clean-up of the nugget trap without a protective cover of sand in the nugget trap will result in some fine gold being scoured out of the nugget trap. Large gold nuggets will withstand the normal flow of water in the drain trough and will not be scoured out of the nugget trap.

GOLD TABLE FLOTATION

In small scale USA, froth flotation, is almost a lost art. For most operations this method will never be practiced, but for a few, this method could save the mill operator thousands of dollars. Froth flotation using air and flotation reagents have survived the test of time.

Most minerals respond to the modification of particle surface by atoms, ions or compounds from aqueous phase, thereby aiding selective sorption of collector agents.

Minerals can be made to float or sink. Air bubbles attach themselves to the oil coated mineral to be floated and will form froth at the surface. This froth can be dispersed into the tailings or with the use of pipes and air jets; they can be discharged into the concentrate bins.

Discovery of mineral flotation occurred when miners discovered gold floating on top of the water in their gold pans. Most libraries will carry books explaining the principles of flotation.

CRUSHING

Jaw for primary and cone crusher for secondary crushing. (See Glossary)

GRINDING

Conventional grinding must be analyzed using the performance characteristics of the mill for the rock type. Hammer and impact mills are designed for soft materials with no more than 5-10% silica. Rolls should be used for dry soft friable ores. Excessive maintenance and downtime are associated with these mills.

Combinations of rod and ball mills continue to dominate the serious mining operations around the world. Characteristics of a combination rod and ball mill circuit include:

- High unit power efficiency.

- Low steel consumption per mt of ore. Depending on ore hardness and other factors steel consumption will range from ½ lbs. -3lbs mt.

- Low mechanical and process risk.

- High controllability of plant capacity and product size.

- Necessity for a three or four stage crushing plant.

- Necessity for more grinding units than a single stage rod or ball mill circuit.

- Design availability of 95%. Generally, rod mill ball mill circuits can be justified for use in long life plants because of their low operating cost. Single stage wet rod mills are normally used in minerals processing plants using the RP-4 shaker tables. Advantage of rod mills include the ability to feed larger and harder feed product, low operating costs and close control of size without creating excessive slimes.