To start the discussion on grinding circuits I would like to begin by showing you some simple Flowsheet SCHEMATICS of some sample circuits, but before I do there is one thing that I must explain for the schematics to make sense. When the ore is put into the first piece of equipment for grinding, water is added to it to form a SLURRY. This water addition is very important, it makes the rest of the separation process possible as you will see a little later.

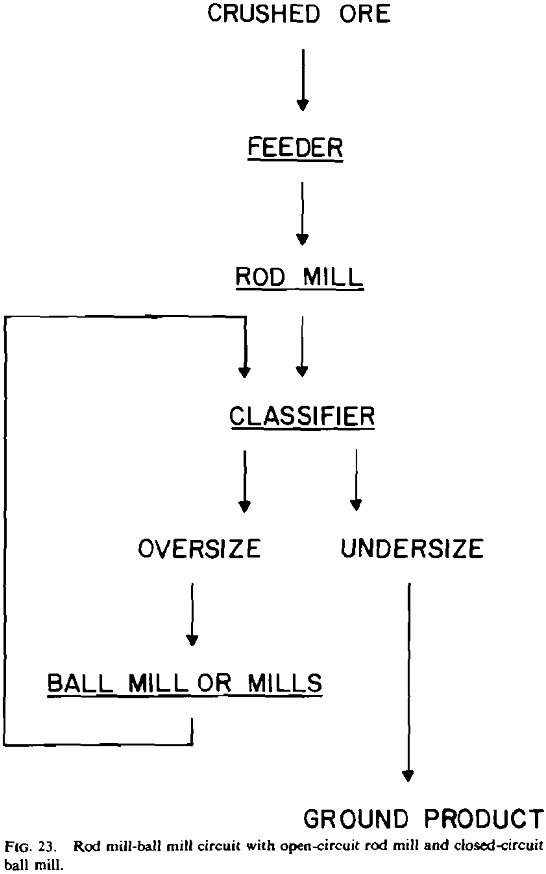

To design a circuit there is some information that has to be learned. The HARDNESS OF THE ORE, the TONNAGE that has to be ground per hour and the DEGREE TO WHICH IT MUST BE GROUND. Once these three pieces of information has been discovered the design of the circuit can begin. The four circuits that I am going to show you start with the simplest, the one that is grinding the softest ore to the coarsest grind.

The ore is simply brought from the fine ore storage area and run into one end of the grinding machine called a MILL, the mill grinds it and mixes it into a slurry which is sent to the next stage of processing.

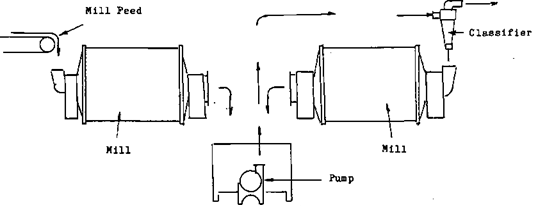

Our second flow sheet, has a couple extra pieces of equipment added. These are a PUMP and a CLASSIFIER, A classifier is a piece of equipment that separates ground material by size, There are different methods that can be employed to accomplish this, but again that is something that we .will take up in greater detail in further sessions.

This is the path that the ore takes in this circuit. The ore comes from the fine ore storage area to be added to the mill. Again it is ground but this time the ground material is pumped to a classifier to be classified by size. The material that has not been ground enough will be sent back to the mill for regrinding. The material that is ready for the next phase of processing will be sent there.

That brings us to our third circuit. Like the second one, the ore is ground in a mill and sent by way of a pump box to a classifier. Now however there has been a second mill added. The rock that requires further grinding is sent to this mill where it is reground. Once the ore has gone through the mill, it is sent by way of the pump back for reclassification.

These circuits have been getting more and more complex. This is because the ore and the required grind has been getting more and more complicated. The ore in the first one was the softest and the grinding wasn’t critical. In the second one the ore was probably still very soft, but the grind had become critical, therefore it had to have a positive control on it, hence the classification. The third one however has harder ore with a critical grind.

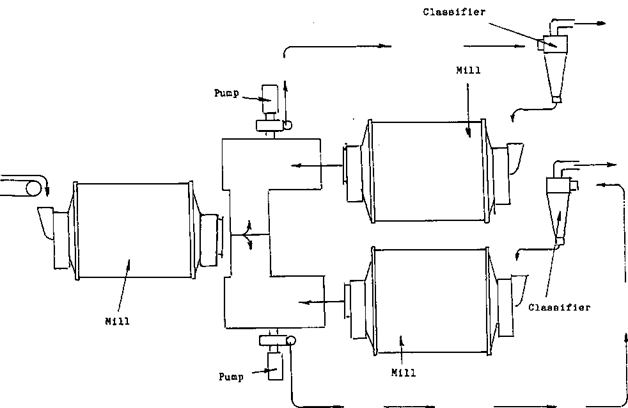

Now for our fourth and final flow sheet. This is one that has been-designed for exceptionally hard ore and/or a grind that must be very fine.

This time the ore is conveyed to the first mill, mixed with water and ground. As it exits the mill it is separated and sent to two different pumps which in turn sends it to be classified. Each of the classifiers will send the material that requires grinding back to its own mill. On this circuit there was one PRIMARY MILL feeding two SECONDARY MILLS each with their own pump and classifier. Again the secondary mill discharge is sent back to its own classifier to be reclassified.