Table of Contents

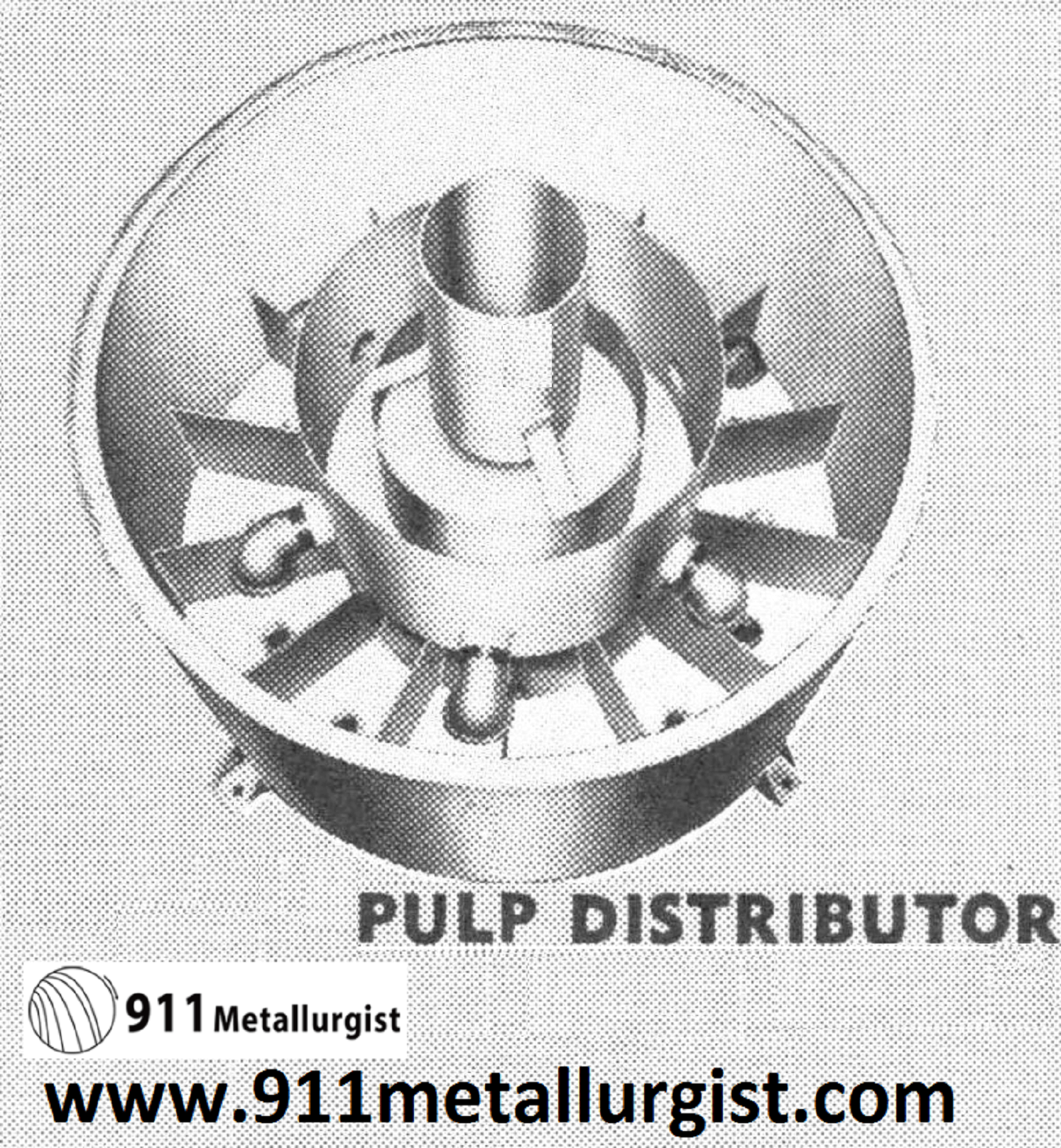

The Slurry Distributor (Self-Rotating or Motorized) is a simple, accurate, positive unit that distributes Slurry automatically wherever material must be distributed to several machines or circuits for treatment. The self-rotating distributor is powered by the force of the material being distributed. No operator or adjustments are necessary.

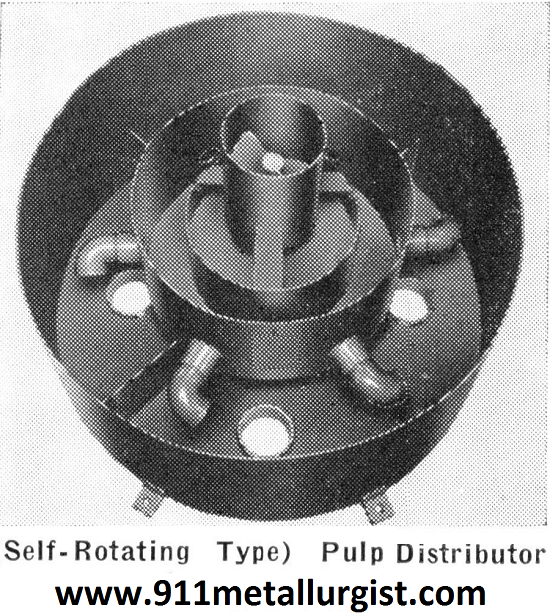

Self-Rotating Pulp Distributor

The Slurry-Pulp Distributor is a simple, accurate and positive unit for distributing pulp in a concentrator where-ever it is necessary to split a pulp stream and send equal quantities of material with identical characteristics to several points or circuits for treatment. It is self-rotating and requires no driving mechanism.

Every operator realizes the importance of eliminating surges and controlling pulp to flotation machines, concentrating tables, etc. By eliminating these surges without frequent operating adjustments, higher efficiency can be obtained as well as increased recovery.

Slurry Distributor are made in two types, the only difference being the bearing mounting of the distributor head. A wide range of standard units makes it possible to select the correct type and size for your installation: from two foot size, built with two to eight compartments and handling 10 to 50 tons; up to the six foot size, built with two to twenty compartments handling 2000 tons or more. Send us a description of your problem and let us recommend the correct pulp distributor. Sizes up to 12′ diameter.

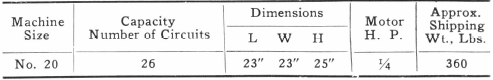

Slurry Distributor Capacity Table

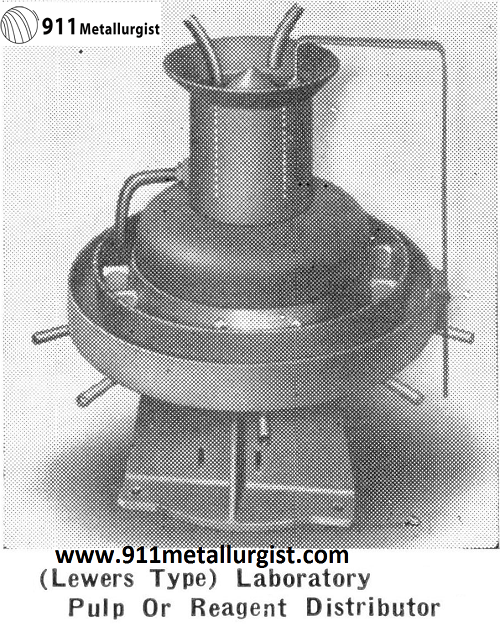

The (Lewers Type) Laboratory Pulp or Reagent Distributor will accurately distribute pulp or reagent in a continuous pilot test plant wherever it is necessary to split these materials. The use of this unit allows the distribution of equal quantities of material with identical characteristics to several points or circuits.

Every test plant operator realizes the importance of eliminating surges and controlling pulp to flotation machines, concentrating tables, etc. By eliminating these surges, without frequent operating adjustments, higher efficiency of test plant operation can be obtained as well as increased recoveries.

This unit will accomplish required control and distribution and is simple to adjust. The material enters a revolving head and passes to a discharge spout, which is revolving with the head, and out into a circular trough. From this compartmented trough as many as twenty-six different points of distribution may be fed from this central distributor. Practically no power is required and units can be furnished with either belt or motor drive.

A small, inexpensive distributor is also available where only a few distributing branches are desired.