Table of Contents

- Continuous Process Development

- Methods and Procedures

- Results of Continuous Heavy Liquid Process Development

- Test Series A (Steam Stripping With Dry Feed)

- Pre conditioning Circuit

- Cyclone Circuit

- Recovery Circuit

- Test Series B (Steam Stripping With Prewetted Feed)

- Preconditioning Circuit

- Cyclone Circuit

- Recovery Circuit

- Test Series C (Steam Consumption)

- Preconditioning Circuit

- Cyclone Circuit

- Recovery Circuit

- Test Series D (Steam-Stripping Time)

- Preconditioning Circuit

- Cyclone Circuit

- Recovery Circuit

We are continuously engaged in research activities to develop or improve methods of utilizing our mineral resources. One such method, heavy liquid separation (HLS), has long been a recognized laboratory technique to separate minerals but only in recent years has this method been considered as a continuous process. The best prospects appear to be the direct concentration of minerals to yield marketable products or pre-concentration of ores ahead of a final separation.

Heavy liquid separation is a gravity concentration method based on the simple principle that a material whose specific gravity is less than the liquid’s will float and a material with a greater specific gravity will sink. The use of a heavy liquid with uniform chemical and physical properties potentially offers the best method for gravity separation of fine particles of relatively close specific gravity. The primary reasons that organic heavy-liquids have not been used commercially are that they are expensive and a fully effective or cheap method for their recovery from mineral particles has not heretofore been developed. New and improved heavy liquid recovery systems are under consideration with present emphasis on solvent extraction, thermoevaporation, and water washing.

Although commercial application of the heavy liquid concentration method has not been completely successful, industry has demonstrated the need for such a process, has proven its technical feasibility, and has examined some of its economic aspects. However, the ultimate industrial use of large-scale heavy liquid separation of minerals will depend on continuing research to develop process economics.

Relatively few research programs have dealt with the different aspects of heavy liquid mineral concentration. Interest is presently focused on adopting fluid cyclones to the process but published data on the subject are limited and no continuous information is known. After laboratory investigations were successful in concentrating minerals using HLS cyclones and two new heavy liquid recovery methods were developed by the Bureau, a continuous heavy liquid plant was built at the Bureau’s Tuscaloosa Metallurgy Research Laboratory to verify the proposed system in more detail. The prime objective of the program was to scale up and combine the beneficiation and recovery stages into an effective, continuous, and autogenous process. The 200-pound-per-hour plant was designed to use steam stripping, detergent scrubbing, or a combination of these two recovery techniques. The steam method was initially installed to investigate the influence of detergent addition on the stripping efficiency. Other variables also examined were the steam consumption, stripping time, filtration efficiency, and feed conditions.

The scope of this paper is directed toward the application of HLS cyclone concentration of spodumene and subsequent recovery of the heavy liquid, tetrabromoethane (TBE). This scheme was selected for the present continuous study as it represented a simple HLS operation.

Continuous Process Development

Description of the Ore

Spodumene, LiAl(Si2O6), is a mineral which theoretically contains 8.4 per-cent lithia, 27.4 percent alumina, and 64.5 percent silica. Almost all spodumene is sold through private contracts as concentrates containing 80 percent or more spodumene at a price between $4 and $5 per unit of lithia. Ore deposits are generally found in granite pegmatites associated with the minerals, quartz, feldspar, mica, and often beryl. Although trace amounts of denser minerals are sometimes present in the ores, spodumene with a specific gravity of 3.1 is significantly denser than the major gangue minerals, the specific gravities of which range from 2.5 to 2.8.

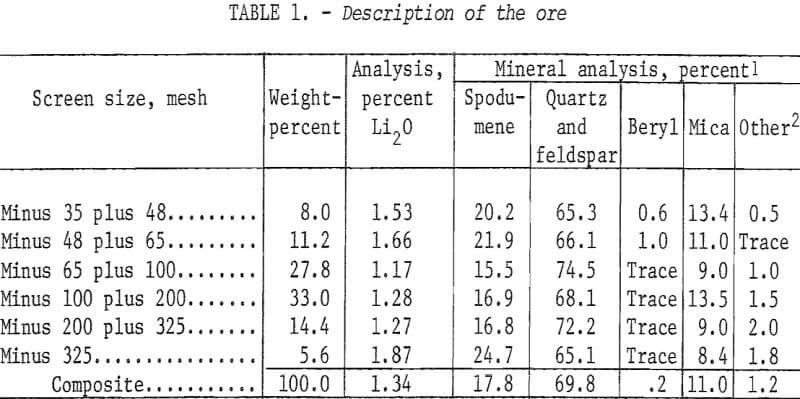

A composite sample of minus 3/8-inch spodumene ore was obtained from the Kings Mountain region of North Carolina. The ore was crushed dry to minus 28 mesh using a jaw crusher and rolls in closed circuit with vibrating screens. This preparation provided the minimum amount of fine comminution. Table 1 gives the size distribution of the test sample including the mineralogical and chemical analyses of each size fraction. Petrographic examination showed that the spodumene crystals were completely liberated at all sizes given in the table.

Description of Heavy Liquid

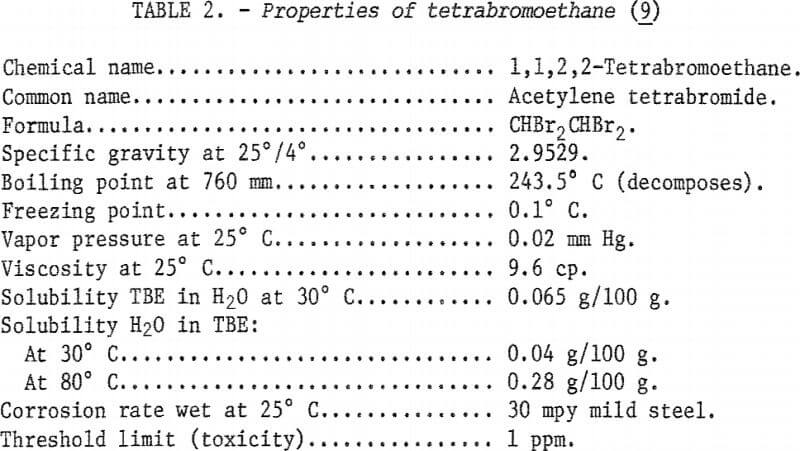

Prior investigators have shown tetrabromoethane (TBE), also known as acetylene tetrabromide (ATB), to be suitable for the separation of a variety of minerals and is adaptable to various heavy liquid recovery schemes that have been proposed for natural ores. Spodumene has been separated from its quartzitic gangue in batch testing using pure tetrabromoethane.

One of the heavy liquids in common use, TBE is priced at about 65 cents per pound in the United States. Large-scale production from the Dead Sea brines in Israel has suggested that a price of 30 cents per pound is possible provided there is sufficiently large industrial demand.

When pure, TBE is colorless, nonflammable, relatively stable, immiscible with water, and has a specific gravity of nearly 2.96. Some properties of tetrabromoethane are given in table 2.

Because of the toxicity of the TBE, a safety program was established to insure that personnel working on the project were provided with maximum safety. This program included medical examinations, air pollution control, safety procedures , and regulations. The Bureau of Mines in conjunction with the U.S. Public Health Service collaborated in developing the safety standards for use when handling large quantities of heavy liquids. Acknowledgment is gratefully given to the Dow Chemical Company for its assistance in this safety program.

The safety design of the continuous plant equipment was centered around exhaust ventilation furnished by two 8,000-cfm blowers. Each piece of equipment in the operation was hooded with an airflow of at least 100 cfm per unit. During normal operation this arrangement was satisfactory in keeping the vapor level below 1 ppm threshold limit. Since TBE vapors are relatively heavy and tend to accumulate at floor level, additional ducts were spaced about the laboratory floor to insure air movement in this region. The major problem with this type of venting system is that dead air pockets form when several ventilation outlets would draw against one another. The exhaust of the ventilation system poses a potential air pollution problem due to volatilized or decomposed TBE vapor. Design of the blower stacks was such that the exhaust air was mixed with auxiliary fresh air to reduce concentration of any contaminants. However, in a commercial operation it would be anticipated that a wet scrubber or activated charcoal filter would be preferred to eliminate any possible external air pollution.

Monitoring of the air in, the working area provided a short-term measure of the TBE vapor concentration in the heavy liquid laboratory area. Volumetric air samples were taken using silica gel to collect the TBE vapor. The gel was analyzed by X-ray fluorescence and reported as parts per million TBE in the air. Samples were taken at least daily and every hour during the continuous operation.

Because of the aqueous recovery system employed in the continuous operation , it is necessary to know the solubility of TBE in water over a moderate temperature range. These data permit estimation of the heavy liquid losses with the water phase and determine if corrective measures are needed to prevent a pollution problem. A search of the literature did not reveal any detailed solubility information and laboratory determinations are underway.

Description of Continuous Operation

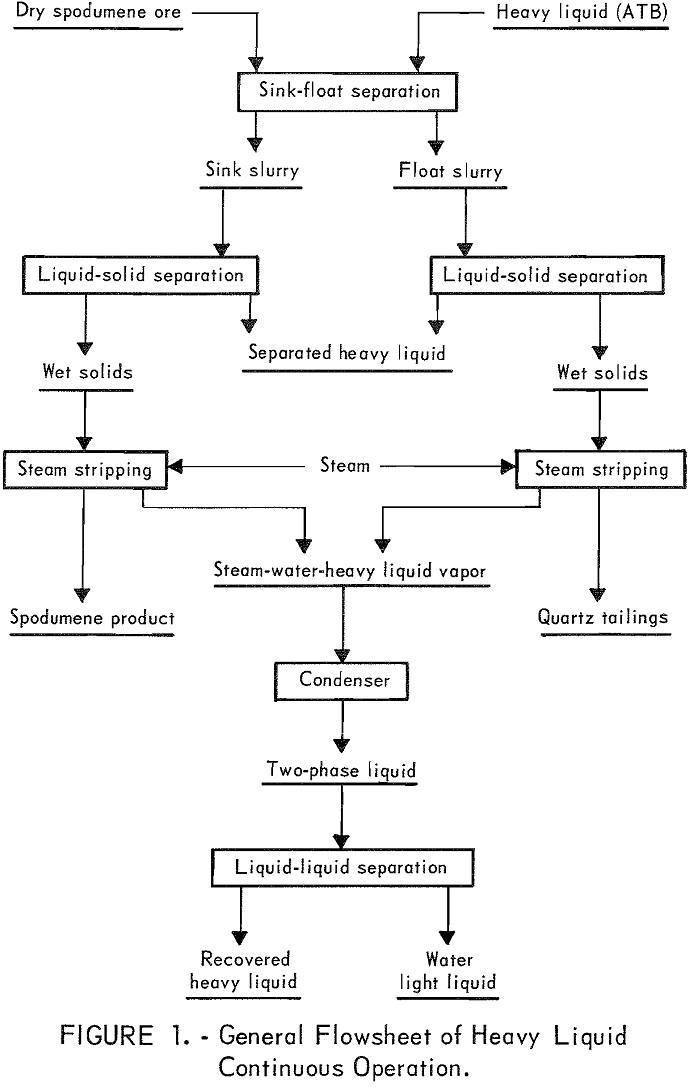

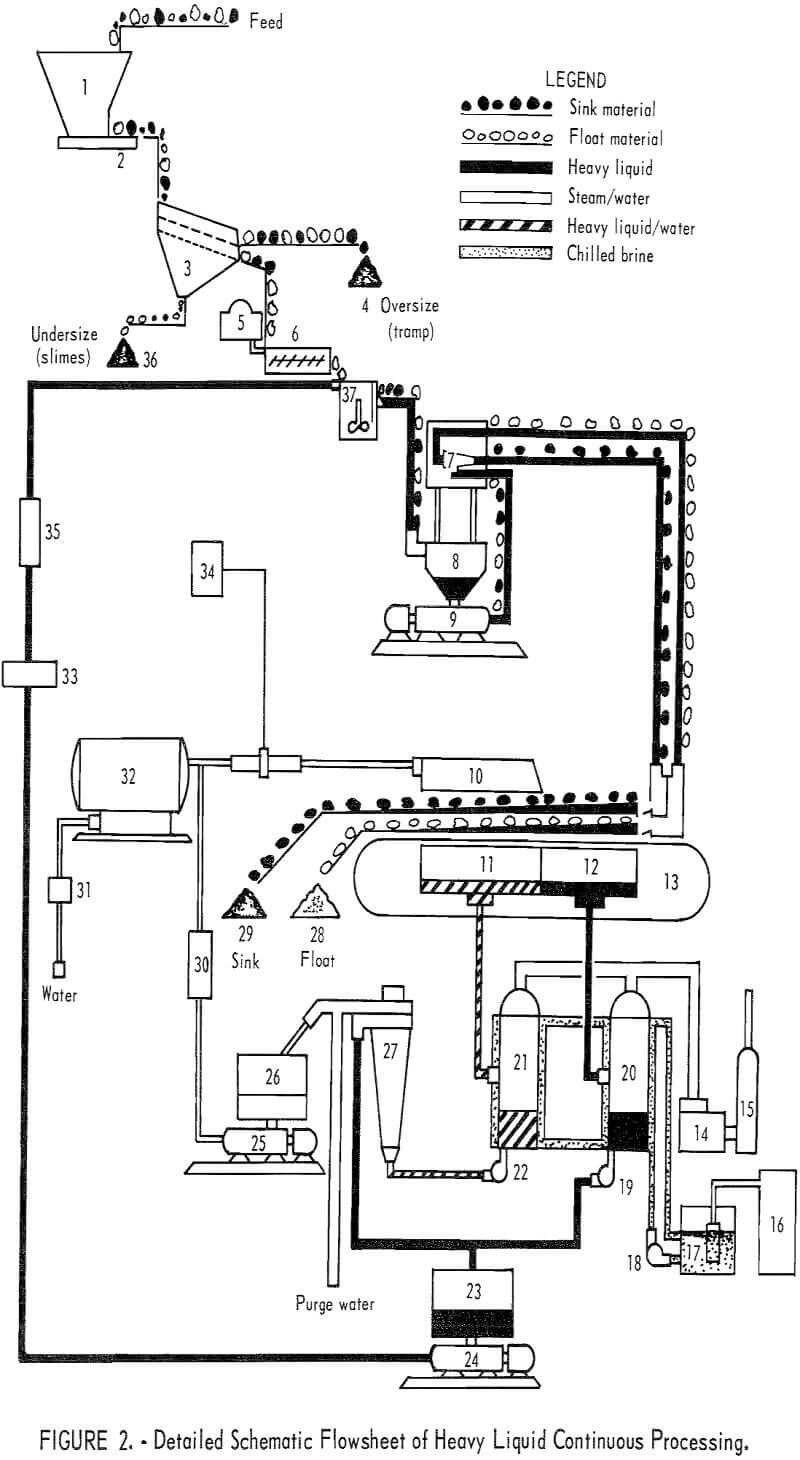

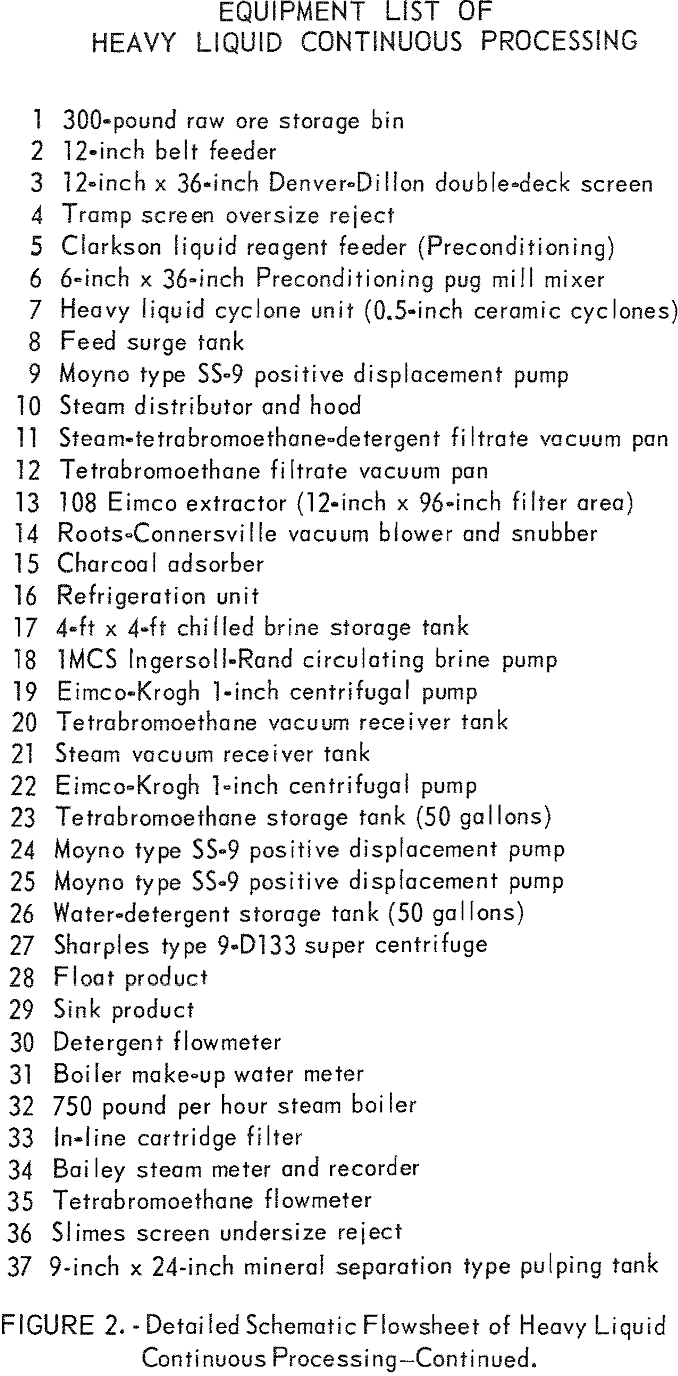

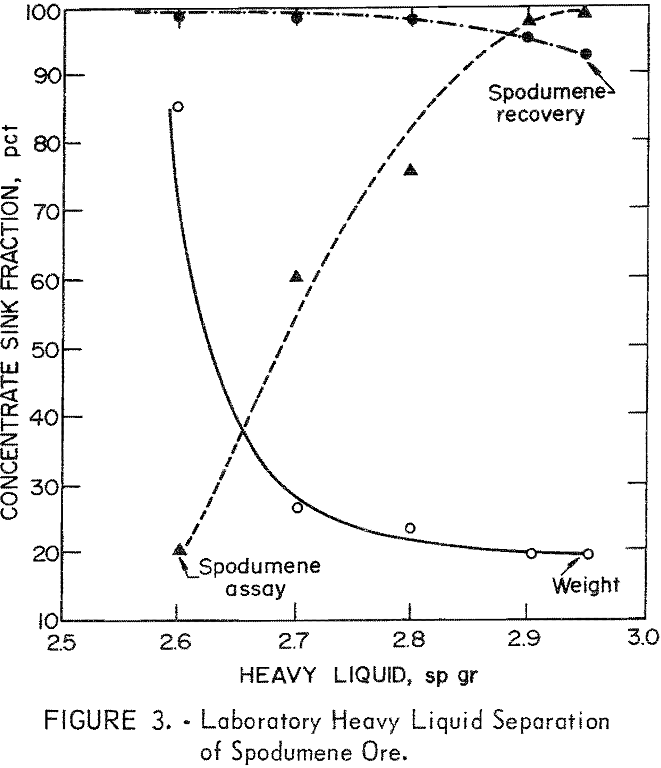

Figure 1 gives the general flowsheet used for the continuous heavy liquid operation and figure 2 shows a more detailed schematic diagram of the different flows and various pieces of equipment. Standard, commercially available equipment is used throughout. Bench-scale sink-and-float tests were conducted at various liquid densities to determine the permissible operating gravity range. The results of these tests are given in figure 3 and indicate that commercial grades of spodumene products can be produced at specific gravities ranging from 2.85 to 3.1.

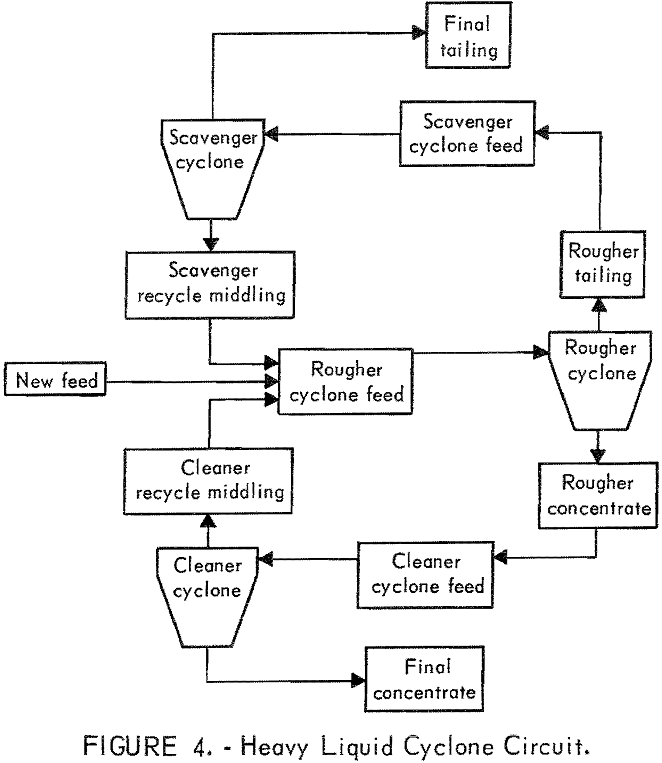

After the dry ore is pulped with pure acetylene tetrabromide in a conditioner, the heavy liquid separation of the minerals takes place in three ½-inch ceramic cyclones fitted with 0.09-inch vortex finder opening and 0.11-inch apex diameter. Figure 4 shows the arrangement of rougher, cleaner, and scavenger cyclones. The cyclone feed density is maintained between 10 and 15 percent solids. Cyclone pressure is set at about 90 psig in the rougher unit and 20 psig in the scavenger and cleaner units. Because of the small opening in the cyclones, a 1-by 3-foot vibrating screen is used to remove any tramp 28-mesh oversize material that might plug the units. Initially the minus 200-mesh fines were also removed, but preliminary test runs indicated that this was unnecessary. Feed containing up to 10 percent minus 200 mesh has been processed without difficulty, but above this level the filtration of the heavy liquid from pulp was difficult and the mineral separation was poor.

After the spodumene is separated from the quartz gangue, both slurries are fed to a 108 Eimco Extractor with a divided horizontal belt. The spodumene and quartz pulps are fed to the filter at about 6 and 16 percent solids, respectively. The first 20 inches of the 12- by 96-inch Poly-P 873 filter belt are used for liquid filtration and the remaining 76 inches are used for steam stripping. Approximately 97 percent of the original heavy liquid fed to the system is removed by direct filtration leaving a filter cake about ½ inch thick arid containing 15 percent liquid. The blower type vacuum pump normally pulls a vacuum of from 2 to 3 inches of mercury. The filtered heavy liquid is recovered in a filtrate tank and pumped to a storage tank for recirculation into the system. Slimes in the liquid which pass through the cloth medium are removed from the circuit via an in-line cartridge filter.

Removal of the remaining heavy liquid entrained in the filter cake is accomplished by passing the material under a steam hood. Low-pressure steam at about 260° C is supplied to the stripping operating through a manifold enclosed in a vapor-tight hood over the filter. A dilute solution of commercial detergent, Rohm & Haas Trition X-100, may be added by injection into the steam line.

After stripping, the water-tetrabromoethane emulsion and steam are pulled through the filter vacuum chamber and into a large filtrate tank. It had been hoped that the expansion of the vapor in the tank plus its exposure to the cool surface of the tank body would decrease the temperature enough for vapor condensation. After startup, it was apparent that the quantity of steam needed for the stripping process required additional cooling capacity to prevent losses through the vacuum exhaust system. Therefore, the filtrate tank was altered into a jacketed condenser with inserted cooling coils. Chilled brine was circulated through the jacket and coils.

The aqueous emulsion of tetrabromoethane is recovered in the bottom of the condenser-filtrate tank and pumped to a Sharples liquid-liquid centrifuge. The heavy phase (TBE) discharge from the unit flows directly into a storage tank for recirculation in the system. The light phase (water) may be reused or discarded.

Methods and Procedures

To insure circuit stability the continuous runs were conducted for at least 2 hours. The sampling of such small flow rates employed in this size of continuous operation can interrupt the system. Therefore, the sampling was performed every 15 minutes to minimize circuit fluctuations and to provide maximum information. Operating data such as temperatures, pressures, and meter readings were recorded for functional evaluation and to indicate process stability. Certain process flows could not be sampled but could be computed. Internal checks of these flow rates, and analysis, were made to insure that the calculated values were reasonable. These included a feed grade check, a filtration check, and a heavy liquid recycle check. These checks were reliable within ±10 percent.

The heavy liquid recovery circuit was evaluated on the amount of residual TBE remaining on the ore after filtration and steam stripping. Because of the small size of the continuous operation, fluctuations were amplified with progression of the material through the plant and therefore the steam-stripping results were more variable than other data. Since steam stripping was the final stage of the process, filter cake samples were taken every 5 minutes to obtain more reliable data. The reported composite analysis was the average of these individual samples except those which were obviously erratic. Such periodic high assays were found to coincide with the time lag during the material balance sampling and were attributed to an unstable process condition.

A recording steam meter, an integrating steam meter, and metered steam boiler water input provided an estimate of the steam consumption within the desired 10 percent values. However, the distribution and recovery of the condensed water was hampered by steam leakage, the filter vacuum exhaust steam, and water spillage. The aqueous phase flow through the plant was the most difficult to determine and gave the least reliable results.

In commercial plants, sink-float methods have been used for control to estimate the percentage of spodumene in the product. In the present investigation, all the samples were analyzed by standard sink-float methods using pure TBE at a density of 2.96. Reliability of the sink-float determinations was indicated by the calculated feed grade analysis obtained by material balances. The calculated grade of feed was 16.1 percent spodumene with a standard deviation of ±1.5 percent. This value includes the experimental errors due to sampling, weighing, assay, and rounding the computations. Periodic sampling of the actual feed gave 17.0 percent spodumene with a standard deviation of 0.7 percent. It is worth mentioning that a correlation has been obtained between the usual chemical determination of Li2O and sink-float results.

Samples from the filter prior to steam stripping always contained more than 5 percent TBE and were dried under a hood, the loss in weight being assumed to be volatilized tetrabromoethane.

The quantity of tetrabromoethane remaining on the mineral surface after steam stripping was determined by two methods: (1) chemical determination and (2) X-ray fluorescence. Other methods are also known; for example, iodometric, colormetric, infrared, and gas chromotography. Because of the number of samples and the speed of determination, the chemical method was used whenever possible. It was periodically checked by the X-ray fluorescence method. Erratic results were encountered with the chemical method at very low TBE concentrations and a minimum detectable limit was set at 0.02 percent TBE (0.40 lb/ton). The X-ray method was used successfully down to 0.005 percent TBE (0.10 lb/ton).

The chemical determination of TBE was adapted from a technique suggested by P. Knight. In this method a 20-gram sample of the ore was placed in a flask containing 100 ml of isopropyl alcohol and agitated for 10 to 15 minutes to dissolve the TBE. It was found that with the spodumene samples only one alcohol wash was necessary to extract the residual TBE. However, depending on the mineral structure this washing procedure will vary with different ore matrices. The alcohol containing the residual TBE is filtered from the sample, dehydrobrominated by an excess of 0.1 normal potassium hydroxide and back titrated with 0.1 normal hydrochloric acid.

X-ray fluorescence determination of residual TBE was by an indirect method. Comparison standards were made by adding known amounts of potassium bromide (KBr) to dry feed samples of the ore. These standards provided a reference curve which was used to compare against unknown test samples. The amount of bromine in the test sample was thus determined and reported as equivalent percent tetrabromoethane.

Results of Continuous Heavy Liquid Process Development

Because of the larger amount of experimental data generated during this study, the reported results are given as a composite average and a standard deviation. To compare the results of the different test runs, the data were statistically analyzed using the Student’s T test at a 95-percent confidence interval.

Test Series A (Steam Stripping With Dry Feed)

A basic problem in the heavy liquid recovery process is the economic effectiveness of the steam-stripping circuit. Batch testing showed that a solution of detergent injected into the steam enhanced the heavy liquid removal from mineral surfaces. Three test runs were conducted using, respectively, a 1-percent detergent solution injected into the steam, steam with an equivalent amount of water but without the detergent, and dry steam. Test A-2 was to discover if the detergent were responsible for any difference in steam stripping or if the water addition would act as a displacement type of wash.

In addition to investigating the influence of steam quality in steam stripping, basic operational data were to be obtained from continuous processing. During all three runs the cyclone and direct filtration operations were tested under similar conditions and an estimate of the system variability was determined.

Pre conditioning Circuit

During the aforementioned three runs the new ore to the continuous operation was fed dry without any preconditioning.

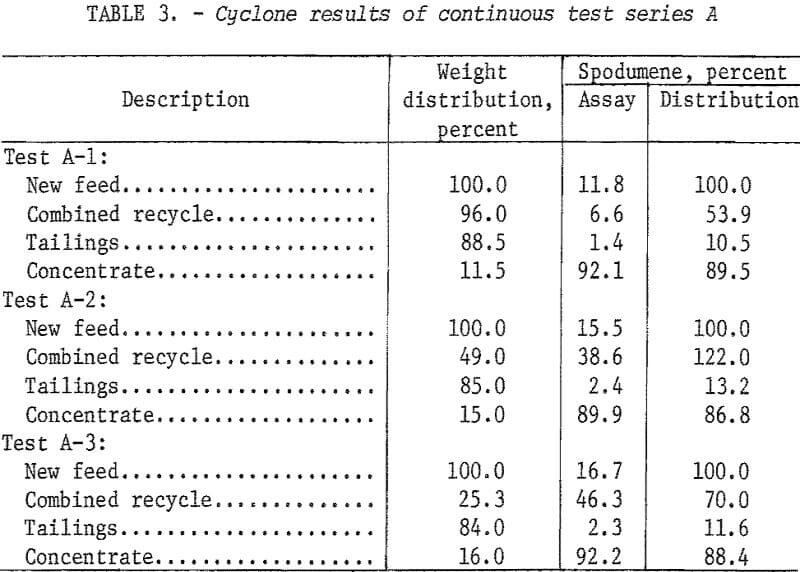

Cyclone Circuit

In this first series of runs no attempt was made to study any of the variables in the cyclone HLS circuit. The important separation parameters had been previously investigated. The average feed rates of the runs were, respectively, 878 g/min at 19.8 percent solids, 629 g/min at 11.7 percent solids, and 629 g/min at 11.9 percent solids.

Overall results are shown in table 3. Statistically no significant difference was detectable between the concentrate grades and the spodumene recoveries of the individual runs, even though the feed rate of A-1 was noticeably high and there were major fluctuations in the circulating loads of the cyclone. The average concentrate grade of the three test runs was 91.4±5.2 percent spodumene with an average recovery of 88.5±4.8 percent. A detailed analysis of the individual mesh sizes of the product was most revealing in that 80 percent of the minus 200-mesh material was recovered as an acceptable product.

Recovery Circuit

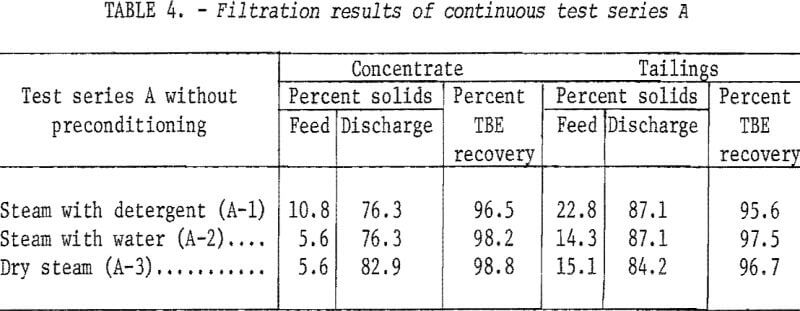

The major portion of the heavy liquid is initially recovered by simple solid-liquid separation in the filtration section of the Eimco extractor. Table 4 shows the results of the three runs compiled from individual samples. The filtration time was approximately 2 minutes.

The heavy liquid recovery from the concentrate filter cake was slightly higher than the recovery from the tailings filter cake. This is understandable because the liquid:solid ratio in the cyclone concentrate product is higher than in the tailings product and both products filter to about the same weight-percent of liquid. The overall TBE recovery from the three runs was 96.9±0.5 percent. No significant difference was noted between the TBE recoveries of the three runs. Nor was there any difference detected between the pulp consistency of the spodumene concentrate filter cake (79.7±8.1 percent) and that of the quartz tailings filter cake (86.8±1.9 percent) even though the cake thicknesses were, respectively, 1/16 inch and 3/8 inch. Therefore, it was concluded that there was no difference between the filtration qualities of the spodumene concentrate and of the quartz tailings. The overall pulp consistency of the combined filter cake was calculated to be 83.7±2.1 percent solids, equivalent to 390 pounds of residual TBE per ton.

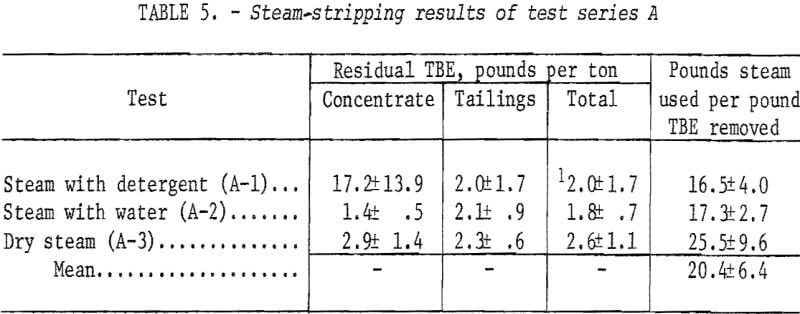

The amount of steam used in each of the three runs was about 3.1 tons per ton of ore. In test A-1, the detergent addition was 4.4 pounds per ton of feed. The final filter cake moisture was about 5 percent. The time of TBE stripping was between 6 and 7 minutes. The data used for comparing the steam- stripping tests are given in table 5.

The residual TBE in the quartz tailing was compared statistically against that in the spodumene concentrate. In tests A-2 (wet steam) and A-3 (dry steam) no significant difference was detected between the two products. The residual TBE of the tailings and concentrates of A-2 and A-3 were therefore combined. In test A-1 (detergent and steam) it was obvious during the test and from the results that something untoward happened during the steam stripping of the concentrates. Therefore, this particular result was not considered in the evaluation. Tentatively it was assumed that the steam-stripping process worked equally well on both products.

No difference was detectable between results using wet steam or steam with a detergent solution added. Therefore, the two results were combined to give an average residual TBE of 1.9±0.9 lb/ton. The dry steam results (2.6±1.1) was suspiciously high. At a 90-percent confidence level there was insignificant difference but the difference became significant at a 95-percent level. Additional data were needed to determine if the increase in residual TBE when using dry steam was due to the steam quality or due to experimental error. Results of these three tests indicated that the heavy liquid in the products was reduced to about 2 pounds TBE per ton of ore using about 20 pounds steam to remove each pound of TBE.

Test Series B (Steam Stripping With Prewetted Feed)

Bench-scale investigation suggested that the steam-stripping process was more effective when the incoming ore was previously wetted. It was surmised that this could be due to the fact that most minerals show a high affinity for water but are not wetted by the organic liquids. Although not confirmed it is also possible that preconditioning with certain surfactants may also assist in the steam-stripping process.

The purpose of this series was to study the effect that adding 1.5 percent water to the feed had upon the mineral separation and the steam-stripping efficiency. To further supplement the results from test series A, three runs were made under the same steam conditions. These conditions were conducted using a 1-percent detergent solution added to the steam (B-1), steam with water added but no detergent (B-2), and dry steam (B-3).

Preconditioning Circuit

Sufficient water was added to the incoming feed at the pug mill to produce approximately 1.5 percent moisture in the cyclone feed. Approximately 10 minutes retention time in the pug mill insured thorough mixing of the water and ore to wet the mineral surfaces.

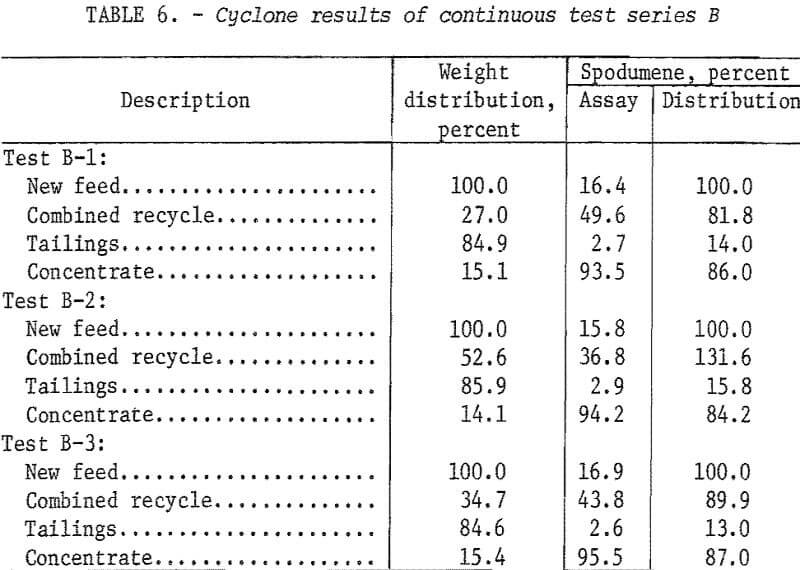

Cyclone Circuit

To compare the results with those previously obtained in test series A (without preconditioning), no operational changes were made in the cyclone circuit. The average feed rates of the individual runs were 615 g/min at 11.3 percent solids, 793 g/min at 15.9 percent solids, and 671 g/min at 11.8 percent solids. Actual preconditioning moisture was determined to be 1.5, 1.7, and 1.8 percent, respectively. Heavy liquid cyclone results are shown in table 6. Statistically tests B-1, B-2, and B-3 showed no significant differences, and the computed overall concentrate grade was 94.4±3.2 percent spodumene with a recovery of 86.0±7.1 percent. Results of a Student’s T test did not show any difference between HLS cyclone results without preconditioning (test series A) and with 1.5 percent water preconditioning (test series B).

That is, within the experimental error of the continuous operation, the addition of 1.5 percent water to the feed did not affect the HLS cyclone concentration of the spodumene ore.

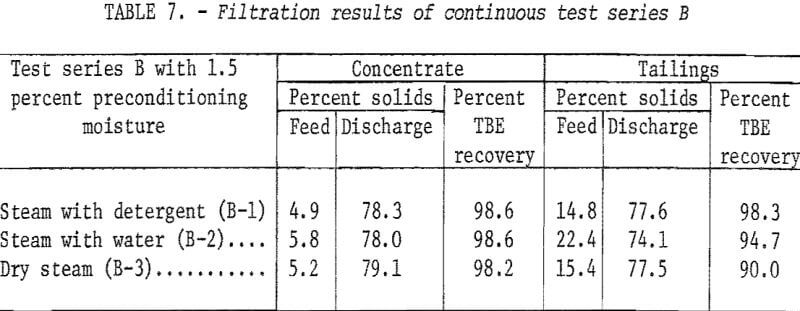

Recovery Circuit

The operating conditions for tests A and B were similar. Thus the influence of preconditioning could be determined, as well as more information about the filtration and steam-stripping properties of the two cyclone products. Filtration time was about 2 minutes. Filter cake thickness was ¼ inch for the concentrate and 3/8 inch for the tailings. The TBE recovery from runs B-1, B-2, and B-3 averaged 95.3±2.9 percent.

The pulp density of the concentrate (78.5±7.3 percent) and the tailings (76.4±5.1 percent) were found to be within experimental error, and gave an average pulp density of 76.8±4.8 percent solids. That is the equivalent to 604 pounds residual TBE per ton, which should be recovered in the steam-stripping circuit.

The results of test series B, as shown in table 7, indicated that heavy liquid recovery by filtration is less effective when the ore was preconditioned. During the preconditioning runs the filter cake pulp density was decreased by 6.9±2.3 percent solids. This meant that the subsequent steam-stripping section must recover an additional 27 pounds TBE per ton of ore. Since the cost of filtration presumably is less than that of steam stripping, this factor must be considered in an economic evaluation of the process.

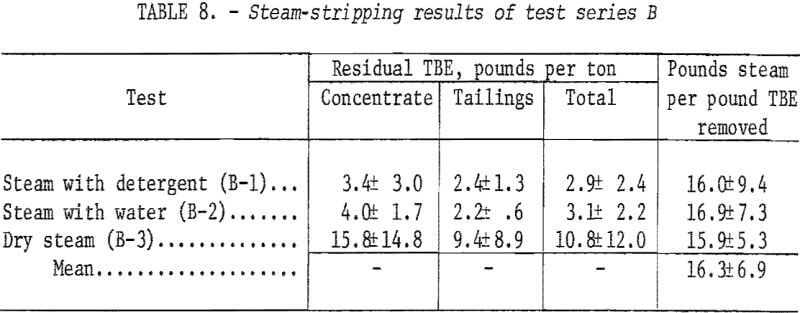

The results of steam stripping after filtration are given in table 8. These three runs corresponded to similar runs in test series A to obtain more conclusive evidence concerning (1) the steam-stripping efficiency of the quartz tailings and spodumene concentrates and (2) the type of steam used during stripping. No difference was detected between the steam consumption of the three runs, which averaged about 4.1 tons steam per ton of ore. The final filter cake moisture was 5 percent. In test B-1 the detergent addition was 6.7 pounds per ton of feed. Average steam-stripping time was about 6 minutes.

The residual TBE in the two filter products were compared statistically to determine their steam-stripping qualities. In all three runs there were no significant differences between the residual TBE in the quartz tailings and in the spodumene concentrates. This was the conclusion from previous tests A-2 and A-3. Therefore it was decided that both the filtration and steam stripping-effectiveness of the concentrate and tailings filter cakes are equal and that there is no advantage in using a split-belt two-product operation.

No difference was detectable between the results using wet steam or steam with addition of a detergent solution. Therefore, the two results were combined to give an average residual TBE of 3.0±2.3 lb/ton. However, the Student’s T test showed that when using dry steam residual TBE increased by 7.8±4.1 lb/ton and confirms that dry steam is not as effective in removing heavy liquids from mineral surfaces as wet steam. The results from these three tests showed that the heavy liquid in the products was reduced to about 3 pounds TBE per ton of ore using about 16 pounds of steam to remove each pound of TBE, The data indicate that preconditioning may assist in the heavy liquid recovery process.

Test Series C (Steam Consumption)

Inasmuch as steam consumption is a major cost item in the recovery process, a study of the effect of this factor is essential. The purpose of the three runs in series C was to investigate the stripping recovery process at 355 pounds of steam per hour (C-1), 415 pounds per hour (C-2), and 480 pounds per hour (C-3), respectively. Detergent was added to the steam in each run.

Preconditioning Circuit

The new cyclone feed was preconditioned at 3.5 percent moisture to compare the HLS cyclone separation at no preconditioning (test series A), 1.5 percent moisture (test series B), and 3.5 percent moisture (test series C), Parenthetically, flocculation of the preconditioned ore occurred near 5 percent water. Under such conditions, heavy liquid separation in the cyclones was impossible. Retention time in the pug mill was approximately 10 minutes.

Cyclone Circuit

Since no operational changes were made in the cyclone circuit and sufficient information had been obtained from previous tests, the individual data from these three runs were not tabulated. Calculated feed grade was 16.5 percent spodumene. The average feed rate was 890 g/min at 13.4 percent solids. The average concentrate grade was 90.9±3.3 percent spodumene, not substantially different from results at 1.5 percent preconditioning with water or without preconditioning. However, the average spodumene recovery of 79.6±4.3 percent was 8.1 percent lower than when the ore was not preconditioned, or preconditioned at 1,5 percent moisture. Tailings and recycle products analyzed 4.4 and 30.9 percent spodumene, respectively.

Recovery Circuit

Since previous tests had shown that the filtration and steam-stripping properties of the two cyclone products were similar, there was no advantage in separating the products. Hence, the divided filter belt construction was removed. In this way many of the physical problems surrounding a two-product circuit were eliminated and reduced fluctuation in the pilot plant. The average heavy liquid recovery was 94.2±2.7 percent with a filter cake density of 74. 9± 3.8 percent solids. This is equivalent to 671 pounds of residual TBE per ton, which should be recovered in the steam-stripping circuit. A Student’s T test did not show any significant change in the percent solids of the filter cake between test series B (1. 5 percent preconditioning) and test series C (3.5 percent preconditioning). Filter time was approximately 2-½ minutes.

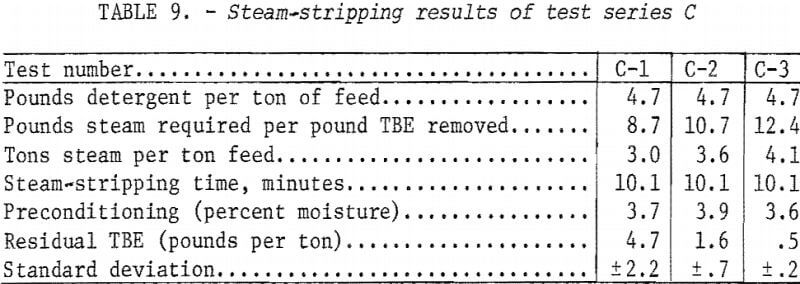

The average steam consumption was 3.0, 3.6, and 4.1 tons steam per ton of feed. Approximately 4.7 pounds of detergent per ton of feed was added to the steam. The steam-stripping time of 10.1 minutes was due to a slower filter belt speed and increased the cake thickness to about ½ inch.

Table 9 gives a brief summary of these three test runs which show the influence of steam consumption. As the steam was increased from 8. 7 to 12.4 pounds of steam per pound of TBE, the residual heavy liquid was reduced from about 5 pounds per ton to 0.5 pound per ton.

To permit a study of the influence of preconditioning on steam stripping, it was hoped that these runs would be made under approximately the same conditions as those of tests A and B. However, an increase in feed rate, coupled with an increase in the steam-stripping time, made a direct comparison invalid. Presumably the increase in preconditioning water to 3 percent, or the increase in steam-stripping time, or a combination of both, substantially reduced the residual TBE to less than 1 pound per ton. It is also true that the single product filter belt arrangement gave less steam loss. Steam consumption per pound of heavy liquid was lower in these tests, yet the TBE was more effectively removed from the mineral surfaces.

Although the changes in conditions in these tests make difficult a numerical comparison with previous runs, the most important questions concerning the heavy liquid recovery process were answered. That is, it was proven that tetrabromoethane can be continuously recovered from mineral surfaces by steam stripping, with residual heavy liquid losses less than 1 pound per ton.

Test Series D (Steam-Stripping Time)

The purpose of test series D was to investigate the relationship between steam-stripping time and heavy liquid recovery. Previous investigation indicated that steam-stripping time was an important factor in the recovery of heavy liquid. For example, the batch results showed that the residual TBE at 10 minutes stripping time would be between 3 and 8 pounds per ton, decreasing to about ½ and 3 pounds per ton at 15 minutes, depending on the test conditions. The results of test C, using 10 minutes stripping time, indicated a similar relationship in the continuous operation.

Varying the stripping time in the continuous circuit presented considerable difficulty. A variable-speed drive mechanism was installed on the Eimco extractor to change the filter belt speed. However, decreasing the belt speed to obtain a steam-stripping time in excess of 10 minutes produced a filter cake of unacceptable thickness. Therefore, other means of changing the stripping time were attempted.

One method of accomplishing this end would be to decrease the feed rate and filter belt speed simultaneously in order to maintain a reasonable filter cake thickness. Identical conditions cannot be achieved but may be approximated in this manner. The major problem that this change presents is the decreased pulp density of the cyclone products, which in turn can reduce the filtration efficiency. Nevertheless, two runs were made at 432 g/min (D-1) and 706 g/min (D-2).

Another method of investigating the effect of steam-stripping time is to increase the stripping area on the filter. Although this is obviously the best means it also is the most difficult to attain because of equipment design. Any increase in steam-stripping area must be at the cost of filtration area since the total available surface area on the Eimco extractor is constant. In test D-3, the filtration length on the belt was reduced from 20 to 15 inches, thereby increasing the length of the steam-stripping section to 81 inches. This was the maximum possible change that could be accommodated. As in test series C, the two cyclone products were combined as feed to the filter belt.

Preconditioning Circuit

Inasmuch as the foregoing three tests were conducted under different conditions, samples from the individual runs were not composited. Feed rates during these runs were 432 g/min at 7.0 percent solids (D-1), 706 g/min at 11.9 percent solids (D-2), and 913 g/min at 16.3 percent solids. Preconditioning moisture was 3.9 percent in tests D-1 and D-2 but was only 3.1 percent in test D-3.

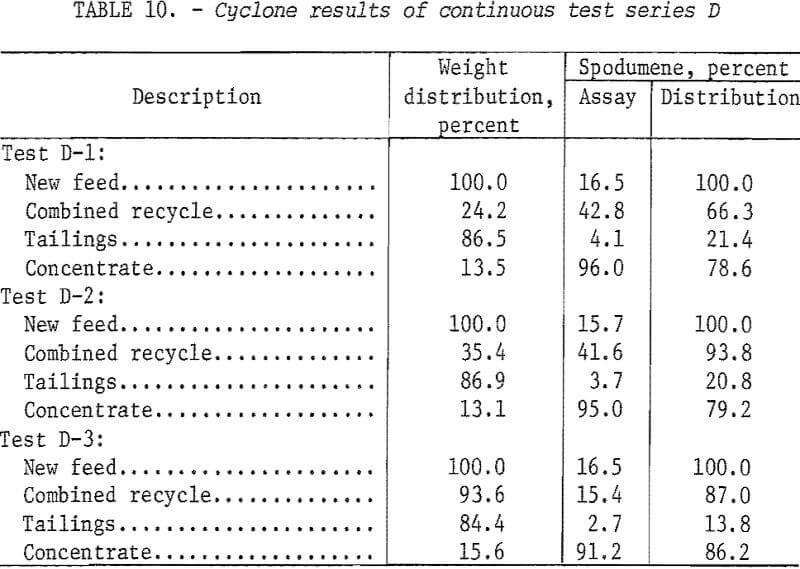

Cyclone Circuit

The results of the heavy liquid separation in the cyclone circuit are given in table 10. A statistical comparison of these three runs showed that although the feed rate of D-1 was almost half the feed rate of D-2, no difference was noted between the grades and recoveries of the respective spodumene concentrates. The grade of the combined concentrates was 95.6±1.0 percent with a 79.6±1.9 percent recovery. These results, obtained at 3.9 percent preconditioning moisture, were not significantly different than those obtained in tests of series C which were preconditioned at 3.6 percent moisture. However, during test D-3, under changed conditions, the preconditioning moisture fell to 3.1 percent. The concentrate assayed 91.2±3.0 percent spodumene, representing a recovery of 85.2±9.8 percent. It thus appears that preconditioning the ore did not noticeably affect the spodumene recovery until the moisture reached about 3 percent.

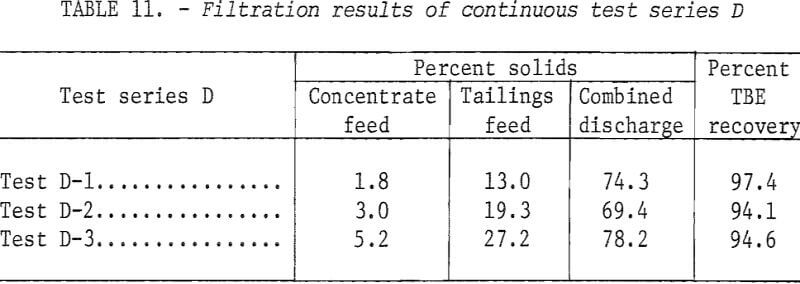

Recovery Circuit

Table 11 gives the results compiled from individual samples in the filtration section. The filtration time of all tests was about 2-½ minutes but because of the variation in feed rate, cake thickness varied from ¼ inch in test D-2 to ½ inch in test D-1, and to 5/8 inch in test D-3. The recovery of the heavy liquid in this section was steady at about 95 percent, but the pulp density of the filter cake products ranged from 69.4 to 78.2 percent solids. Insufficient data were available to conclude if the variation in pulp consistency was due to the difference in filter cake thickness or to fluctuations in the pilot plant operation. The results demonstrate that a high solids content can be obtained with a deep filter bed.

The steam-stripping time in tests D-1 and D-2 was about 9 minutes and was increased to 14 minutes in test D-3. Final filter cake moisture was about 5 percent. Water without detergent was injected into the steam during the stripping process.

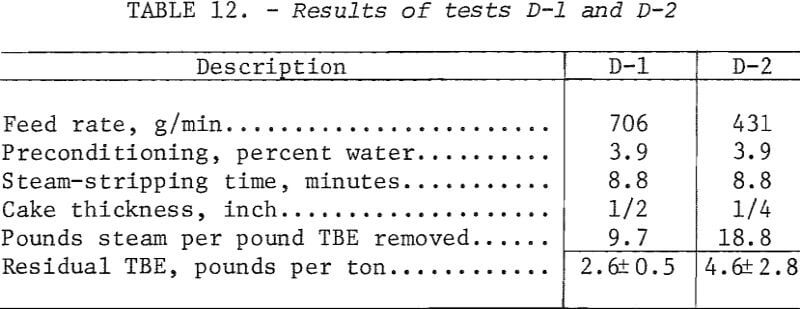

Reduction of the feed rate from 706 g/min (D-1) to 431 g/min (D-2) changed the cake thickness and the steam consumption. A statistical comparison of the residual TBE failed to indicate any difference between the two runs, even though test D-1 had double the steam consumption and gave half the cake thickness. As expected, the thin filter cake resulted in more variation in residual TBE analysis because of the greater probability of steam leakage and channeling. Table 12 gives the condensed data from these two tests.

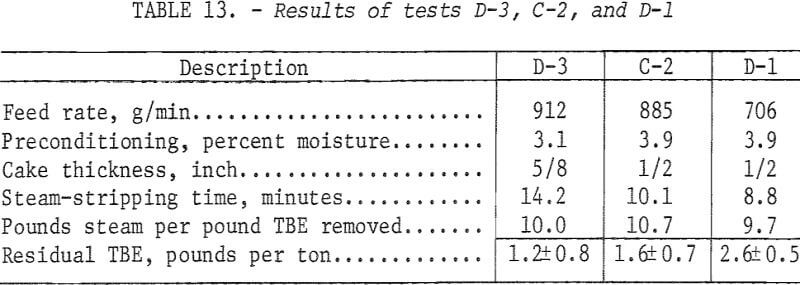

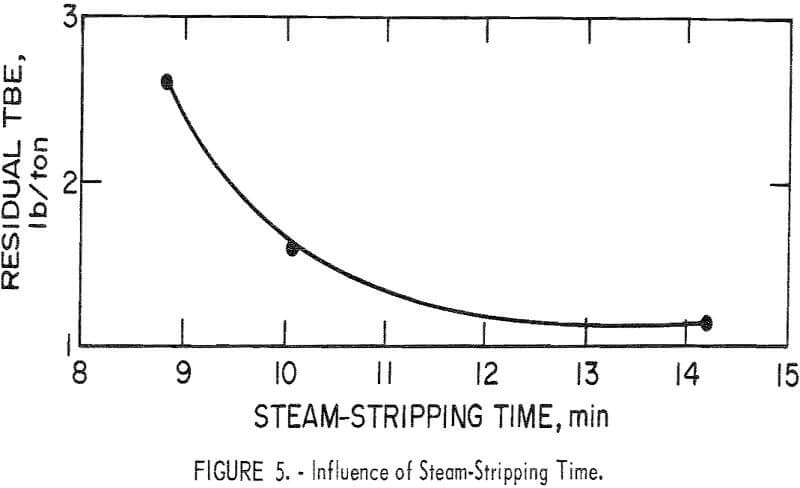

Operating conditions between tests D-1, D-3, and C-2 were very similar except for the steam-stripping time and feed rate. Inasmuch as a considerable variation in the feed rate did not produce a marked difference in cake thickness, with the steam consumption remaining constant, it was surmised that only steam-stripping time was a variable factor. As shown in table 13, increasing the steam time did materially reduce the residual TBE from 2.6 pounds per ton at 8.8 minutes to 1.2 pounds per ton at 14.1 minutes. Figure 5 indicates that the effect of time of steam stripping results in only a slight increase in recovery of TBE after about 10 minutes.

Summary and Conclusions

The continuous HLS study conducted on the spodumene ore verified laboratory test work and produced much of the desired information concerning the application of the heavy liquid separation process to mineral beneficiation.

The research program included a continuing study of the hazards and safety precautions required to adequately handle heavy liquids. It was shown that substantial quantities of tetrabromoethane could be used safely in a minerals beneficiation process when reasonable safety precautions and standards are maintained. No noticeable harmful effect to personnel occurred after 4 years’ exposure. The two major concerns for safety were (1) absorption of the liquid into the body by heavy liquid vapors and (2) direct contact of the heavy liquid solutions to the outer portions of the body. Procedures were developed to monitor the air for TBE contamination, routine medical examinations were established, safety regulations were prescribed, and design features of the pilot plant equipment were formulated.

In the continuous test runs the HLS cyclone concentrates averaged 93.5 percent spodumene. This is well above the concentrate grade normally produced by flotation and therefore the HLS products are considered commercially acceptable. In analyzing the individual mesh sizes, the fine sizes showed better separation than that obtained during the semicontinuous laboratory cyclone tests. The minus 200-mesh fraction in the concentrate, assayed near 80 percent spodumene with about a 75-percent recovery.

Although feed moisture did not influence the spodumene concentrate grade, recovery was susceptible to moisture variation. When the feed contained less than 3 percent water the recovery averaged 86.5 percent spodumene but decreased to 78.5 percent as the moisture was raised from 3 percent to 5 percent water. Above 5 percent water in the feed, the ore flocculated in the heavy liquid pulp.

The direct recovery of the heavy liquid from the cyclone concentrate and tailings by filtration was 95.7 percent. Overall pulp density of the filter cake was 77.8 percent solids. This is equivalent to 572 pounds of TBE per ton of ore which must be recovered by the steam-stripping method. For this particular ore, a filtration time, of about 3 minutes was satisfactory when the amount of minus 200-mesh fines was less than 10 percent of the feed. No difference was detected between the filtration properties of the spodumene concentrate and the quartz tailing.

Results indicated that feed moisture increased the amount of TBE remaining in the cake after vacuum filtration by as much as 180 more pounds of heavy liquid. However, since the moisture may be beneficial in the steam-stripping stage of recovering tetrabromoethane, this decrease in filtration efficiency may be economically justified.

Using low-pressure steam, the continuous results showed that tetrabromoethane could be stripped from the mineral surfaces to where less than 1 pound of heavy liquid remained in the final cake. During laboratory testing a 15-minute steam-stripping time was necessary but only 10 minutes was required in the continuous operation. The amount of steam used was shown to be directly related to the removal of the heavy liquid. Using 3.0 tons of steam per ton of ore the residual TBE was 4.7 pounds per ton but was reduced to 0.5 pound TBE per ton when the steam was increased to 4.1 tons per ton. No difference was noted between the steam-stripping properties of the spodumene concentrate and quartz tailing.

Of the three different steam conditions studied—(1) dry steam, (2) wet steam, and (3) wet steam with detergent added—dry steam was not as effective in removing the heavy liquid from the filter cake as either the wet or detergent type of steam. The tests were inconclusive as to the effect the deter¬gent had on the stripping process.

Although preconditioning the feed with water was shown to assist steam stripping during laboratory tests, this was not conclusively confirmed in the continuous operation. Preconditioning may be effective in improving the steam-stripping efficiency during a continuous process but it is much less than expected.